Waste incineration boiler device

A boiler device and waste incineration technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as the gap in comprehensive utilization, and achieve the effect of high resource recovery and reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

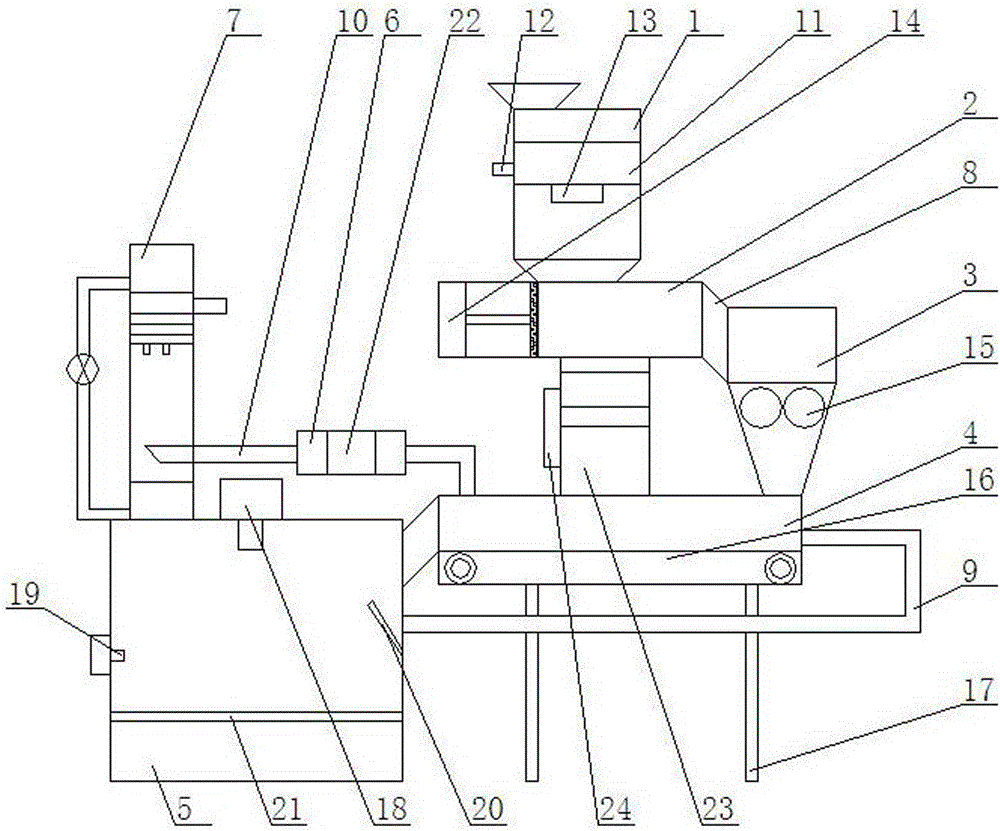

[0026] like figure 1 As shown, a waste incineration boiler device includes a recovery chamber 1, a compression chamber 2, a crushing chamber 3, a drying chamber 4, an incineration power generation chamber 5, a flue gas filtration chamber 6, and a spray treatment chamber 7. The recovery chamber 1 The device is at the top of the compression chamber 2, the compression chamber 2 is connected to the crushing chamber 3 through the inclined conveying pipe 8, the crushing chamber 3 is installed at the upper right end of the drying chamber 4, and the drying chamber 4 is connected to the incineration power generation through the inclined conveying pipe 8 chamber 5, the middle end of the right side of the incineration power generation chamber 5 is connected to the middle end of the right side of the drying chamber 4 through the flue gas pipe 9, and the left side of the top of the drying chamber 4 is connected to the flue gas filter chamber 6 through the flue gas pipe 9, so The flue ga...

Embodiment 2

[0028] like figure 1 As shown, the top of the recovery chamber 1 is equipped with a garbage drop-in opening, and the interior is equipped with a magnetic separation device 11, and the magnetic separation device 11 has a recovery port 12 and a non-recovery port 13.

Embodiment 3

[0030] Such as figure 1 As shown, the hydraulic compression device 14 is installed inside the compression chamber 2, which is composed of a hydraulic drive device, a hydraulic rod, and a compression push plate. The hydraulic drive device is connected to the hydraulic rod, and the hydraulic rod is connected to the compression push plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com