Automatic separating and recycling method of lead hanging stripes and system of the same

A technology of automatic separation and lead hanging strips, which is applied in chemical instruments and methods, solid separation, filtration, etc., can solve the problems of lead waste polluting the environment, achieve low recycling costs, reduce harm to the environment and human beings, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

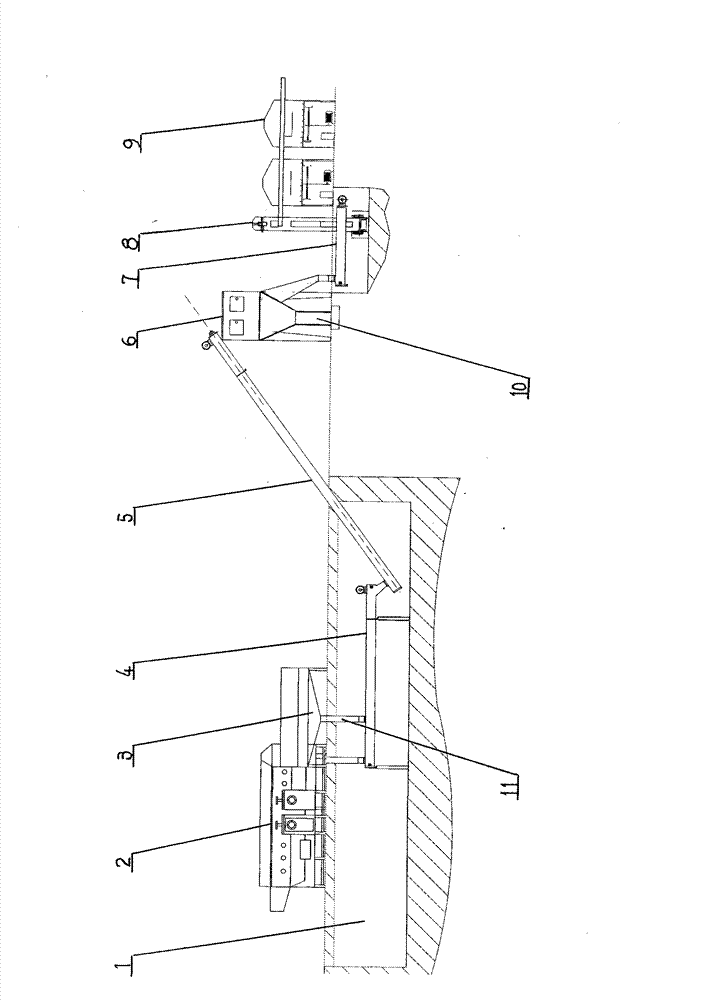

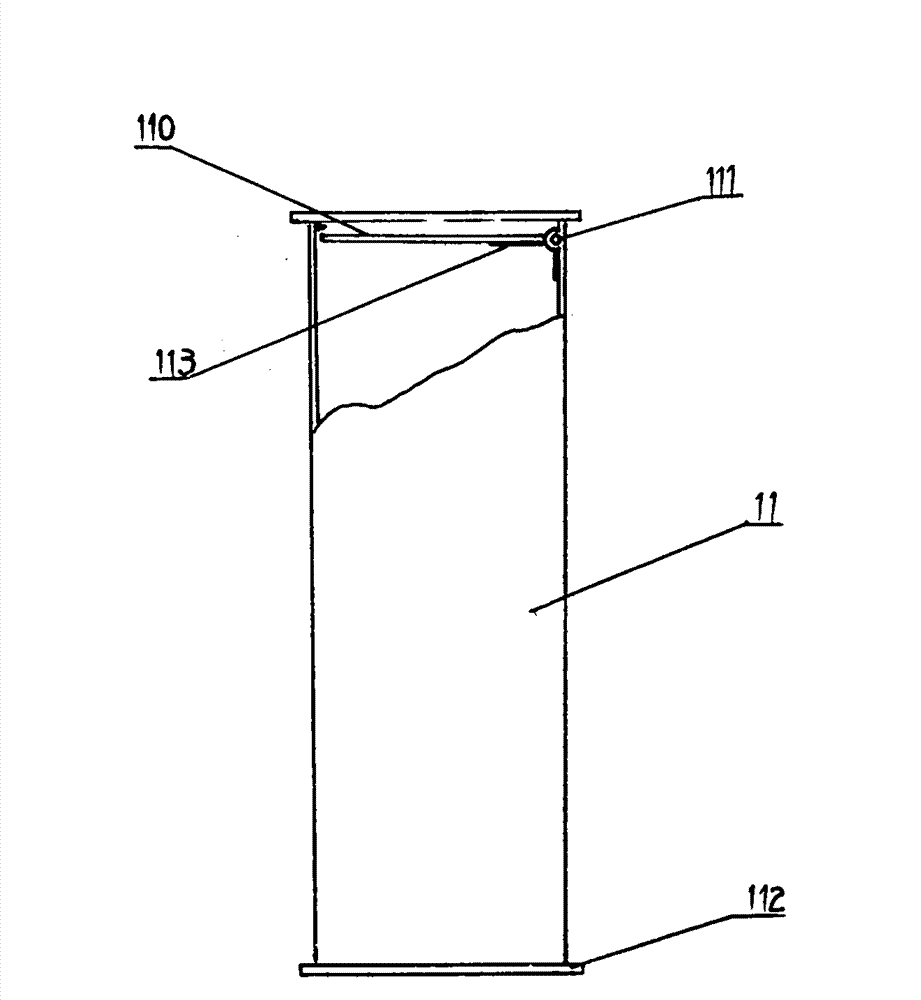

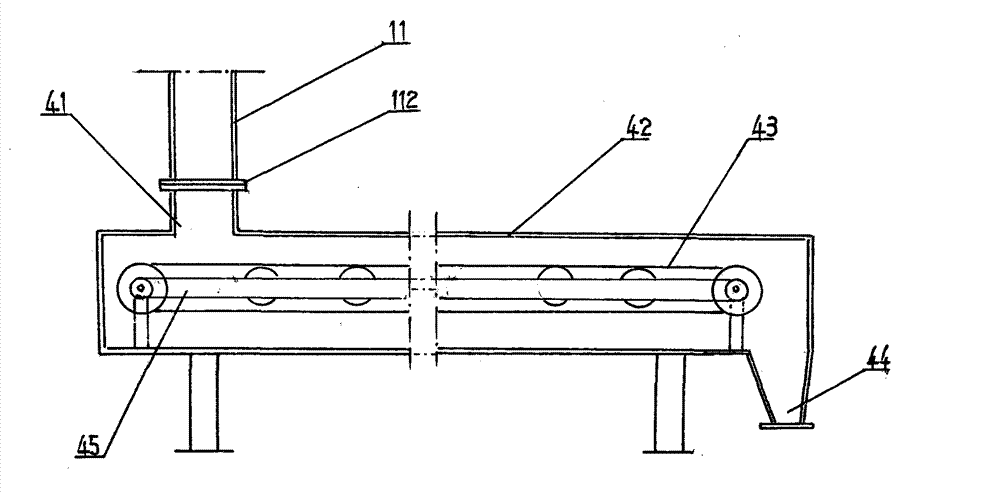

[0025] A method for automatic separation and recycling of lead hanging bars, comprising the following steps,

[0026] (1) Carry out mass production of battery plates, and clearly record the composition, use, and quantity of the lead plates used in the manufacture. The manufacture of battery plates is divided into separate manufacturing processes for positive and negative plates, and the alloy components of the positive and negative plates are different, so they cannot be used in confusion. In order to facilitate recycling and reduce the reuse of raw materials and costs, batch production of battery plates with the same polarity should be carried out, that is, positive plates should be produced in batches at the same time; or negative plates should be produced in batches at the same time. , There is a clear record.

[0027] (2) Seal and collect the lead hanger waste and lead dust produced by the same batch of battery plates. Since a large amount of leftover material will be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com