Single-nozzle internal combustion engine gas-liquid two-phase fuel injection system and method

A technology for internal combustion engines and liquid fuels, applied in fuel injection devices, charging systems, mechanical equipment, etc., can solve problems such as lubrication, heat dissipation, and layout difficulties, and achieve the effects of increased heat transfer loss, extended life, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

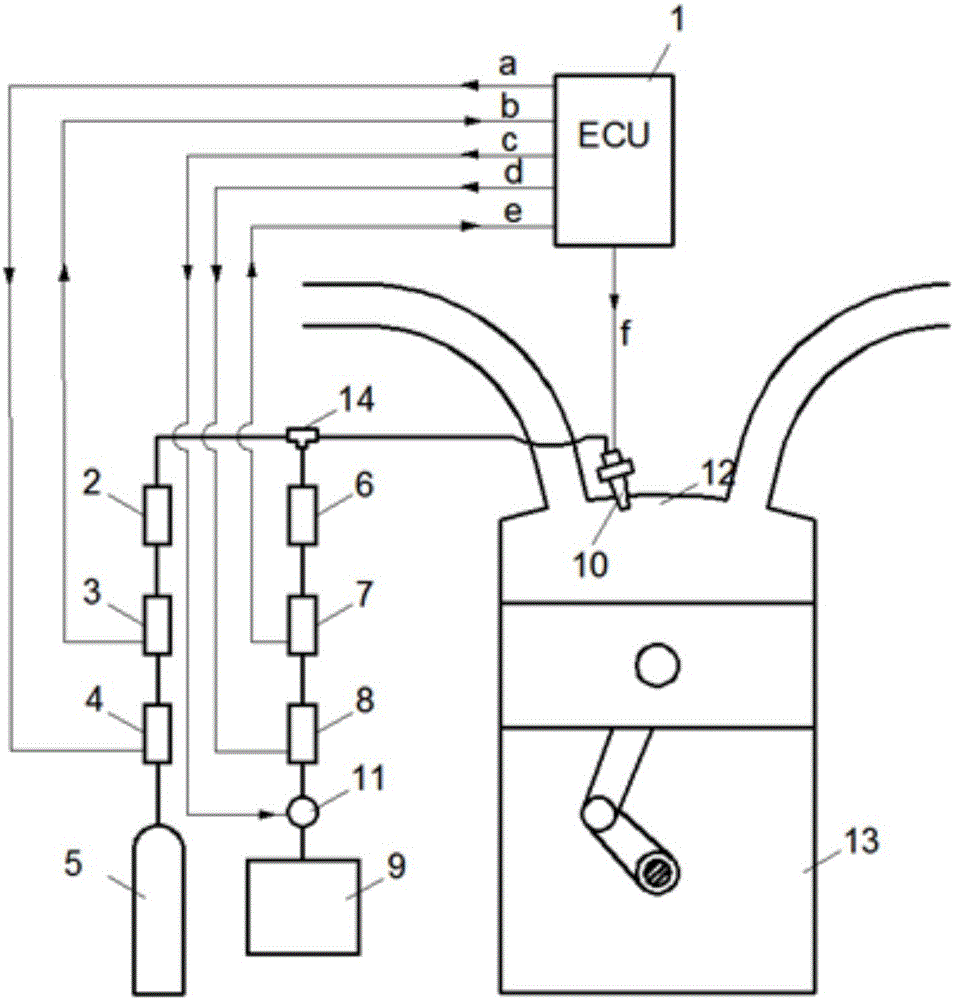

[0026] Such as figure 1 As shown, a gas-liquid two-phase fuel injection system for a single-nozzle internal combustion engine, on the basis of retaining the original engine body 13 and the cylinder head 12 connected with the engine body 13, an electronic control unit 1 and a set of gas Liquid two-phase fuel compound injection system;

[0027] The gas-liquid two-phase fuel composite injection system is characterized by comprising: a gas fuel storage tank 5 , a gas fuel linear solenoid valve 4 , a gas fuel flow and pressure sensor 3 , and a gas fuel check valve 2 . The gas fuel storage tank 5, the gas fuel linear solenoid valve 4, the gas fuel flow rate, the pressure sensor 3 and the gas fuel check valve 2 are connected through a high-pressure gas pipeline;

[0028] The gas-liquid two-phase fuel compound injection system is characterized by comprising: a liquid fuel storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com