Permeable concrete pavement protection agent and preparation method thereof

A permeable concrete and protective agent technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problem of incompatibility between water permeability and surface adhesion, small particle size particles in the pavement surface are easy to run, and water-permeable pavement The layer is prone to efflorescence and other problems, to achieve the effect of preventing concrete efflorescence, improving water permeability, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

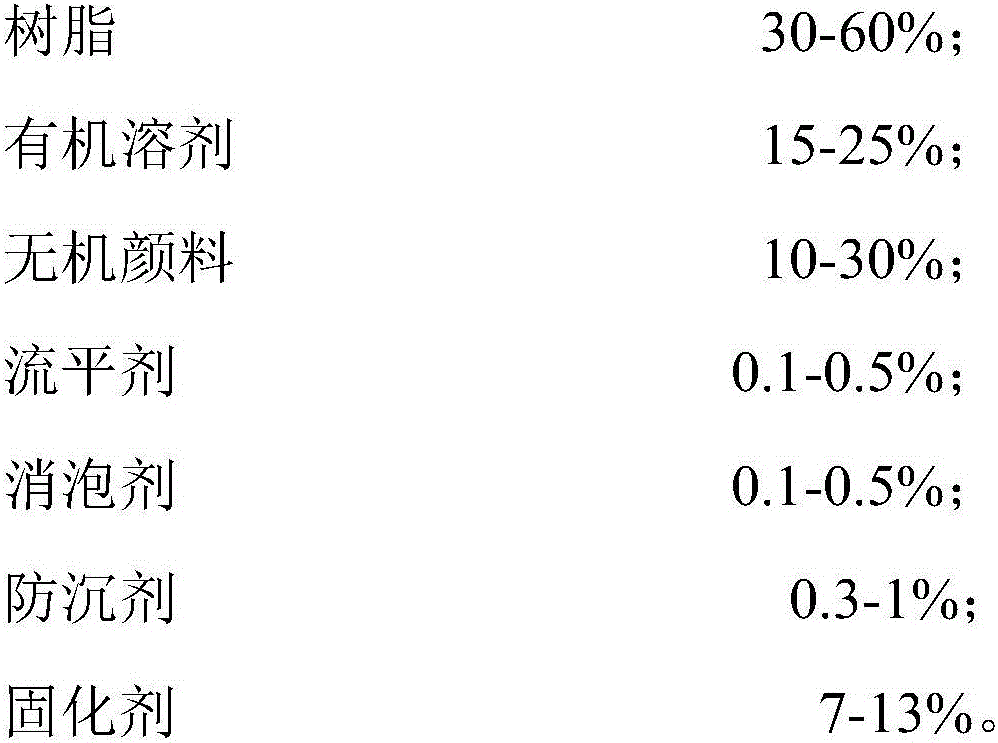

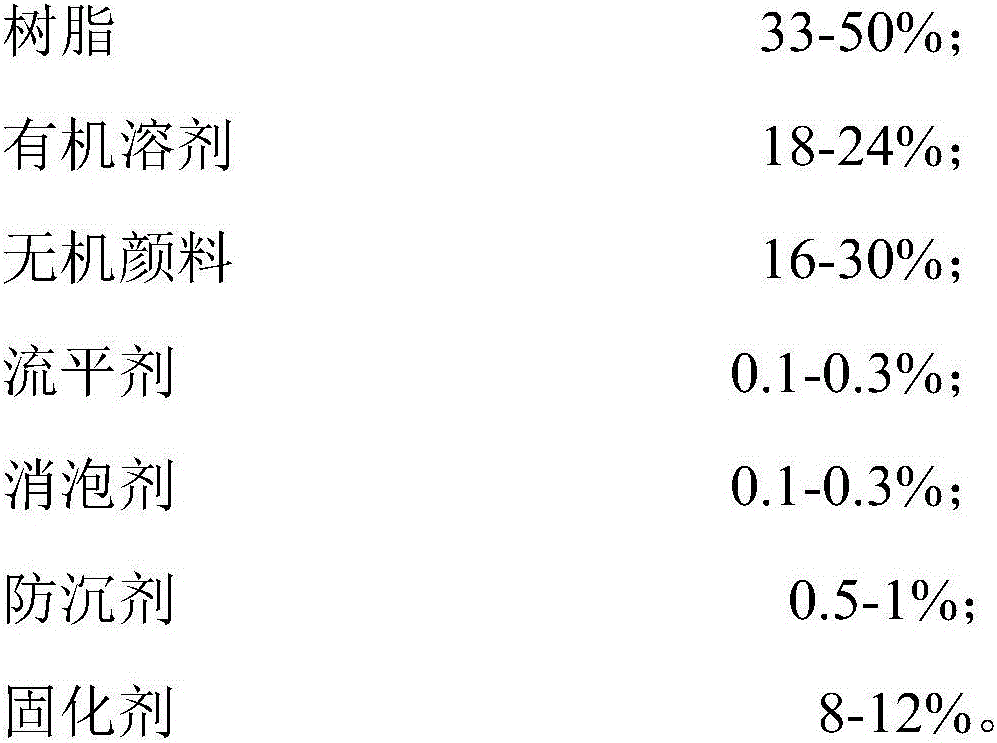

Method used

Image

Examples

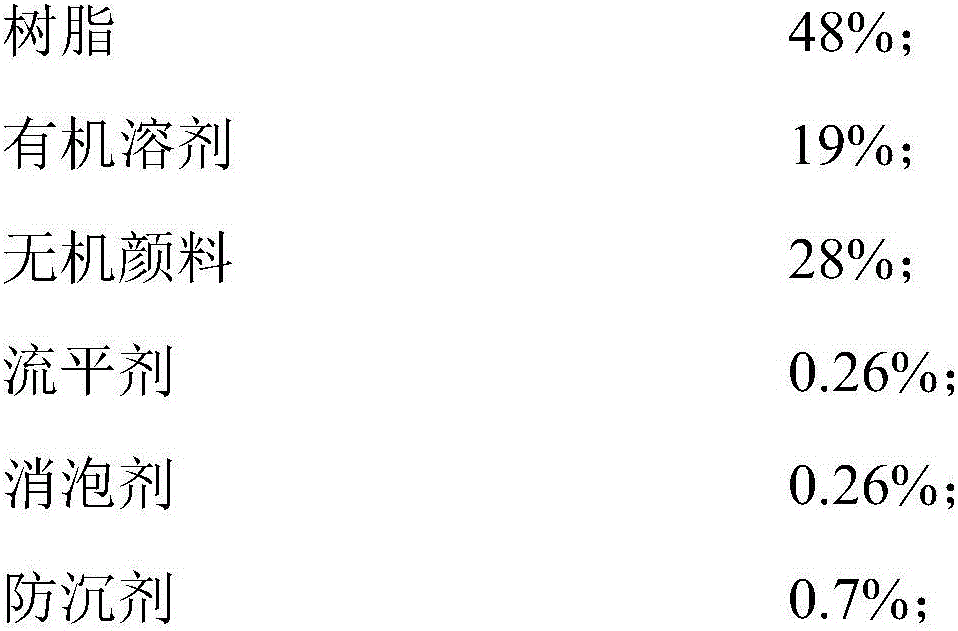

Embodiment 1

[0048] Put 42kg of JF-3X fluorocarbon resin produced by Shanghai Dongfu Chemical into Wuxi Top brand stainless steel mixing tank, and then put the dispersing disc of Jiangyin Fine Chemical Co., Ltd. model FL22 high-speed dispersing machine in the mixing tank. Stir and disperse, then sequentially add 15kg of propylene glycol methyl ether acetate, 20kg of iron oxide red, and 22kg of high-grade clay into the mixing tank, and use a high-speed disperser to disperse and stir at a high speed for 30 minutes to obtain a mixture; then pass the prepared mixture through The horizontal sand mill of Kunshan Zhengdong Industrial Co., Ltd. grinds non-ferrous semi-finished products with a fineness of ≤20 microns. Then disperse the above-mentioned colored semi-finished products through a high-speed disperser, and add 0.15 kg of Deqian Chemical’s brand of Levelol835 acrylate leveling agent, 0.15 kg of Deqian Chemical’s brand of Defom5800F defoamer, and 0.7 kg of Deqian Chemical’s brand of Desettl...

Embodiment 2

[0052] Put 50kg of JF-3X fluorocarbon resin produced by Shanghai Dongfu Chemical into Wuxi Top brand stainless steel mixing tank, and then put the dispersing disc of Jiangyin Fine Chemical Co., Ltd. model FL22 high-speed dispersing machine into the mixing tank Stir and disperse, then add 12kg of trimethylbenzene, 25kg of iron oxide green, and 2kg of wollastonite powder into the mixing tank in sequence, and use a high-speed disperser to disperse and stir at high speed for 60 minutes to obtain a mixture; then pass the prepared mixture through Kunshan The horizontal sand mill of Zhengdong Industrial Co., Ltd. grinds colored semi-finished products with a fineness of ≤20 microns. Then the above-mentioned colored semi-finished product is dispersed through a high-speed disperser, and gradually added 0.2kg of Deqian Chemicals brand is the acrylate leveling agent of Levelol 835, 0.2kg of Deqian Chemicals’ brand is the defoamer of Defom 5800F, and 0.6kg of the BASF brand is 963S polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com