Self-healing nanocomposite film with structural color and its preparation method without changing color with viewing angle

A nanocomposite, viewing angle technology, applied in the field of nanocomposite films and nanocomposite films with structural color, can solve the problems of limiting the application of structural color materials, lack of high mechanical stability, etc., to improve color durability and enhance light scattering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

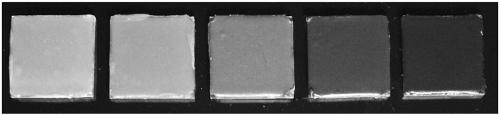

[0028] The surface is modified with octadecyl lipophilic monodisperse silica latex particles with a particle size of 190 nm, carbon black with an average particle size of 25 nm, and the mass ratio of the particles to the monodisperse latex particles is 0, 0.00125, 0.0025 , 0.005, 0.01, polydimethylsiloxane containing amino groups at the end, the content of which is 0.5:1 in mass ratio to monodisperse latex particles, and dimethyl silicone oil with a viscosity of 10 mPa.s, whose content is The mass ratio of polydimethylsiloxane with amino groups at the end is 1:1, dispersed in chloroform to form an emulsion (the mass fraction of monodisperse latex particles is 20 wt%), and the obtained emulsion is heated at a temperature of 20 °C After fully drying, a self-healing blue nanocomposite film with structural color can be easily obtained. After adding carbon black, the saturation of the blue color increases, and the blue color continues to deepen with the increase of the amount of ca...

Embodiment 2

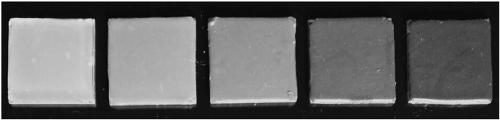

[0030] The surface is modified with hexadecyl lipophilic monodisperse silica latex particles with a particle size of 235 nm, carbon black with an average particle size of 25 nm, and the mass ratio of the particles to the monodisperse latex particles is 0, 0.00125, 0.0025 , 0.005, 0.01, polydimethylsiloxane containing amino groups at the end, the content of which is 0.5:1 in mass ratio to monodisperse latex particles, and dimethyl silicone oil with a viscosity of 10 mPa.s, whose content is The mass ratio of polydimethylsiloxane with amino groups at the end is 1:1, dispersed in chloroform to form an emulsion (the mass fraction of monodisperse latex particles is 40 wt%), and the obtained emulsion is heated at a temperature of After fully drying at 20°C, a self-healing green nanocomposite film with structural color can be easily obtained. After adding carbon black, the saturation of green color increases, and the green color deepens continuously with the increase of carbon black c...

Embodiment 3

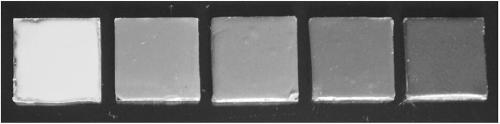

[0032] The surface is modified with eicosyl lipophilic monodisperse silica latex particles with a particle size of 270 nm, carbon black with an average particle size of 100 nm, and the mass ratio of the particles to the monodisperse latex particles is 0, 0.00125, 0.0025 , 0.005, 0.01, polydimethylsiloxane containing amino groups at the end, the content of which is 0.5:1 with the mass ratio of monodisperse latex particles, and dimethyl silicone oil with a viscosity of 10mPa.s, whose content is The mass ratio of polydimethylsiloxane with amino groups at the end is 1:1, dispersed in chloroform to form an emulsion (the mass fraction of monodisperse latex particles is 40 wt%), and the obtained emulsion is heated at a temperature of 20 °C and fully dried, a self-healing red nanocomposite film with structural color was easily obtained. After adding carbon black, the saturation of the red color increases, and the red color deepens continuously with the increase of the amount of carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com