Preparation method of isobutyl cage type polysilsesquioxane modified polyurethane

A polysilsesquioxane and isobutyl technology is applied in the preparation field of isobutyl cage polysilsesquioxane modified polyurethane, which can solve the problems of poor dimensional stability, poor thermal stability, production and application of polyurethane materials restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First place 1.8g of isobutyl cage polysilsesquioxane in a vacuum oven at a constant temperature of 100°C for 24 hours. After natural cooling in vacuum, dissolve it in 3.7g of 4,4'-diisocyanate In benzene methane, stir in a three-necked flask protected by a nitrogen atmosphere at 40°C until the isobutyl cage polysilsesquioxane is completely dissolved to obtain a prepolymer; 21.2 g of polyether polyols with a molecular weight of 3000 were dissolved in the three-necked bottle, and the stirring was continued for more than 2 hours. Then the transparent viscous liquid obtained is evenly spread on a glass plate, placed in a vacuum oven at 25mmHg, and dried overnight at a constant temperature of 60°C to obtain a polyurethane film modified by isobutyl cage polysilsesquioxane (the content of isobutyl cage polysilsesquioxane is 7wt%).

[0020] In order to compare the performance difference between the isobutyl cage polysilsesquioxane modified polyurethane prepared by the method o...

Embodiment 2

[0023] First place 3g of isobutyl cage polysilsesquioxane in a vacuum oven at a constant temperature of 100°C for 24 hours, and after natural cooling in vacuum, dissolve it in 3.7g of 4,4′-diphenyl diisocyanate In methane, stir in a three-necked flask protected by a nitrogen atmosphere at 40°C until the isobutyl cage polysilsesquioxane is completely dissolved to obtain a prepolymer; then, continue to stir in a nitrogen atmosphere and stir Dissolve 16.6g of polyether polyol with a molecular weight of 3000 in the three-necked bottle, continue to stir for more than 2 hours, spread the obtained transparent viscous liquid evenly on a glass plate, place it in a vacuum oven at 25mmHg, 60°C Dry overnight at constant temperature to obtain isobutyl cage polysilsesquioxane-modified polyurethane (wherein the content of isobutyl cage polysilsesquioxane is 13wt%).

Embodiment 3

[0025] First place 4.4g of trihydroxytriisobutyl cage polysilsesquioxane in a vacuum oven at a constant temperature of 100°C for 24 hours, and then dissolve it in 3.7g of 4,4'-diiso In diphenylmethane cyanate, stir in a three-necked flask protected by a nitrogen atmosphere at 40°C until the isobutyl cage polysilsesquioxane is completely dissolved to obtain a prepolymer; 1. Dissolve 11.5g of polyether polyol with a molecular weight of 3000 in the three-necked bottle under stirring, continue to stir for more than 2 hours, spread the obtained transparent viscous liquid evenly on a glass plate, and place it in a vacuum oven at 25mmHg and dry overnight at a constant temperature of 60°C to obtain isobutyl cage polysilsesquioxane-modified polyurethane (wherein the content of isobutyl cage polysilsesquioxane is 22wt%).

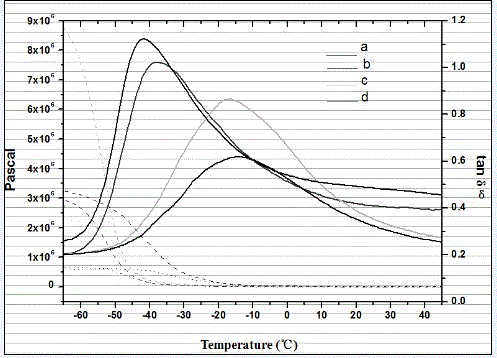

[0026] figure 2 It is the dynamic thermomechanical property spectrum of isobutyl cage polysilsesquioxane modified polyurethane. It can be seen that the glass trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com