Abelmoschus manihot stem and leaf polysaccharide and preparation method and application thereof

A technology of hollyhock, stems and leaves is applied in the field of preparation of polysaccharides of stems and leaves of hollyhock, can solve the problems of waste of resources, lack of effective utilization methods of stem and leaf resources, abandonment and the like, achieves improvement of production efficiency, promotes proliferation of spleen lymphocytes, and facilitates enrichment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Extraction process of hollyhock stem and leaf polysaccharide is preferred

[0030] (1) Optimization of single factor for extracting polysaccharides from stems and leaves of hollyhock

[0031] Take the hollyhock stem and leaf samples and divide them into several parts. After proper crushing, weigh them, add water with a weight ratio of (1:10, 1:15, 1:20, 1:30, 1:40) of the raw materials, and set the temperature at (60°C , 70°C, 80°C, 90°C, 100°C) extraction temperature, extraction (0.5h, 1h, 2h, 3h, 4h), extraction (1 time, 2 times, 3 times). Filtrate, take the supernatant, and measure the polysaccharide extraction rate by the phenol-sulfuric acid method, and the optimal factor index results are shown in Table 1.

[0032] Table 1 Univariate analysis

[0033]

[0034]

[0035] (2) Orthogonal optimization test for extraction of polysaccharides from stems and leaves of hollyhock

[0036] Taking solid-liquid ratio, extraction time, and extraction temperatu...

Embodiment 2

[0042] Embodiment 2 A kind of separation and purification process of hollyhock stem and leaf polysaccharide, it comprises the steps:

[0043] (1) Get 1.0 kg of hollyhock stems and leaves, after crushing, add 20 kg of water according to the optimized extraction method in Example 1, heat and reflux at 100° C. to extract twice, each time for 2 hours, and filter to obtain the filtrate.

[0044] (2) Take the filtrate obtained in step (1), concentrate it to 1 L, add ethanol until the alcohol content is 80%, let it settle for 24 hours, and centrifuge to separate the solid and liquid to obtain the alcohol precipitate.

[0045](3) Take the alcohol precipitation precipitate obtained in step (2), add water to dissolve, separate through AB-8 macroporous adsorption resin column chromatography, and elute with 10% ethanol aqueous solution to obtain the eluent.

[0046] (4) Take the eluate obtained in step (3), concentrate it appropriately, and ultrafilter it through a hollow cellulose ultraf...

Embodiment 3

[0048] Embodiment 3 A kind of separation and purification process of hollyhock stem and leaf polysaccharide, it comprises the steps:

[0049] (1) Get 2.0 kg of hollyhock stems and leaves, after crushing, add 40 kg of water according to the optimized extraction method in Example 1, heat and reflux at 100° C. to extract 3 times, each time for 1 hour, and filter to obtain the filtrate.

[0050] (2) Take the filtrate obtained in step (1), concentrate it to 1 L, add ethanol to reach an alcohol content of 70%, let it settle for 24 hours, and filter to obtain an alcohol precipitate.

[0051] (3) Take the alcohol precipitation precipitate obtained in step (2), dissolve it in water, separate it through D101 macroporous adsorption resin column chromatography, and elute with water to obtain an eluent.

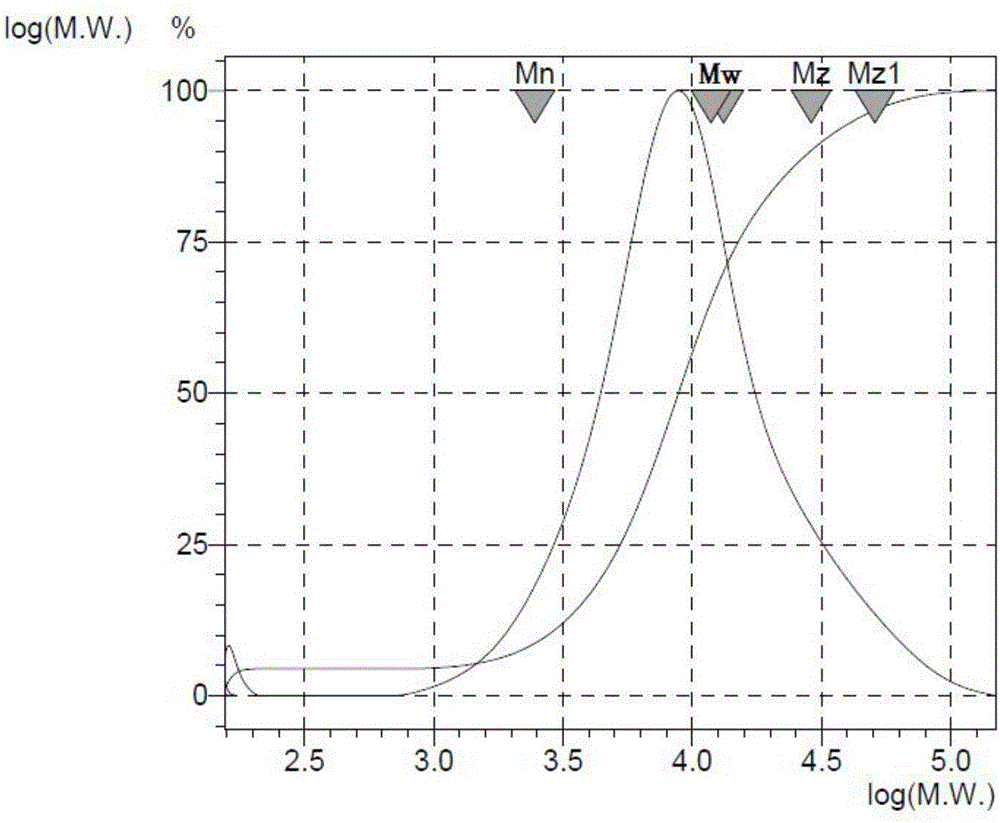

[0052] (4) Take the eluate obtained in step (3), concentrate it properly, and ultrafilter it through an ultrafiltration membrane, take some samples with a molecular weight ranging from 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com