A kind of resin impregnated ceramic composite material and preparation method thereof

A ceramic composite material, resin infiltration technology, used in pharmaceutical formulations, dental preparations, compression mold cups, etc. Bending strength, effect of avoiding volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a resin-infiltrated ceramic composite material, comprising the following steps:

[0041] (1), mixing the mixture of thermosetting agent and methacrylate compound to obtain mixed resin;

[0042] (2), infiltrating the mixed resin obtained in the step (1) into the ceramic green body to obtain ceramics infiltrated with resin;

[0043] (3) Solidify the resin-infiltrated ceramic obtained in the step (2) to obtain a resin-infiltrated ceramic composite material.

[0044] In the present invention, the mixture of the thermal curing agent and the methacrylate compound is mixed to obtain a mixed resin for use. The present invention has no special requirements on the mixing process, and the mixing method known to those skilled in the art can be adopted; in the embodiments of the present invention, the mixing method of the mixture of the heat curing agent and the methacrylate compound It is specifically the way of ordinary stirring or m...

Embodiment 1

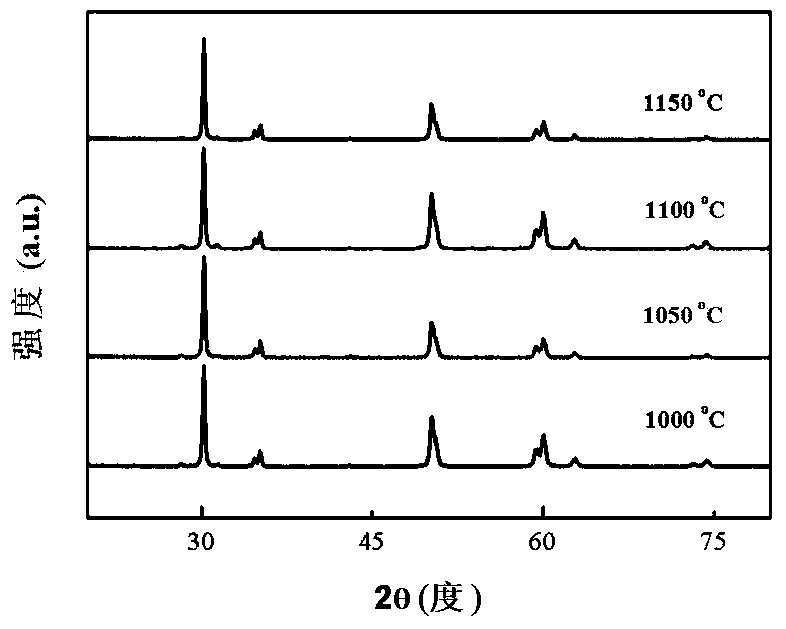

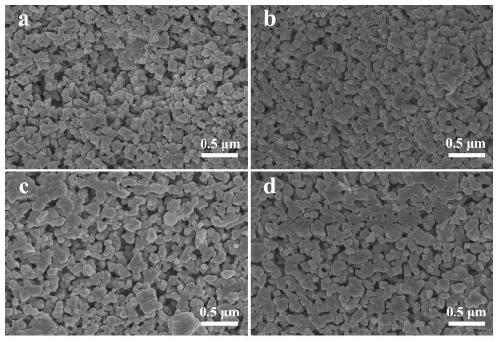

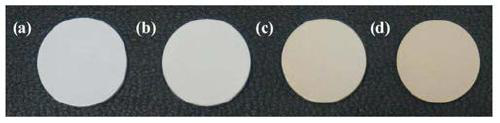

[0067] Weigh 4.5g of 3Y-TZP, use a tablet press to press the powder into a ceramic green body precursor, the pressure is 4MPa, and the holding time is 3min; use cold isostatic pressing to compress the zirconia ceramic green body to obtain a denser ceramic green body Blank, the pressure is 220MPa, the pressure holding time is 1min; the ceramic green body is sintered in the air atmosphere to obtain the ceramic green body for use, wherein the sintering temperature is 1000°C, and the holding time is 2h. Mix bisphenol A glycerol dimethacrylate and tri(ethylene glycol) dimethacrylate with a mass ratio of 1:1, and stir for 2 hours with magnetic stirring; add the curing agent benzoyl peroxide to the above mixed resin Continue to stir for 2 hours to obtain a resin solution. According to the mass fraction of the mixed resin, the amount of curing agent added is 1%; the spare ceramic body is immersed in the resin solution, and placed in a vacuum environment with a vacuum degree of -0.1MPa....

Embodiment 2

[0071] Weigh 4.5g of 3Y-TZP, use a tablet press to press the powder into a ceramic green body precursor, the pressure is 4MPa, and the holding time is 3min; the ceramic green body obtained by pressing the zirconia ceramic green body by cold isostatic pressing, The pressure is 220 MPa, and the holding time is 1 min; the ceramic green body is sintered in an air atmosphere to obtain a ceramic green body, the sintering temperature is 1050° C., and the holding time is 2 h. Mix bisphenol A glycerol dimethacrylate and tri(ethylene glycol) dimethacrylate with a mass ratio of 1:1, and use magnetic stirring for 2 hours to obtain a resin solution; the curing agent benzoyl peroxide Add the above resin solution and continue to stir for 2 hours. According to the mass fraction of the mixed resin, the amount of curing agent added is 1%; immerse the ceramic green body in the mixed resin solution, place it in a vacuum environment, and infiltrate it for 4 hours; The material was cured in a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com