A medical wastewater treatment process

A wastewater treatment and wastewater technology, applied in natural water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of poor wastewater removal effect, low organic matter and ammonia nitrogen removal rate, high cost, and improve sludge Settling effect and dehydration performance, improving system resistance to poison shock, decolorization effect, and activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

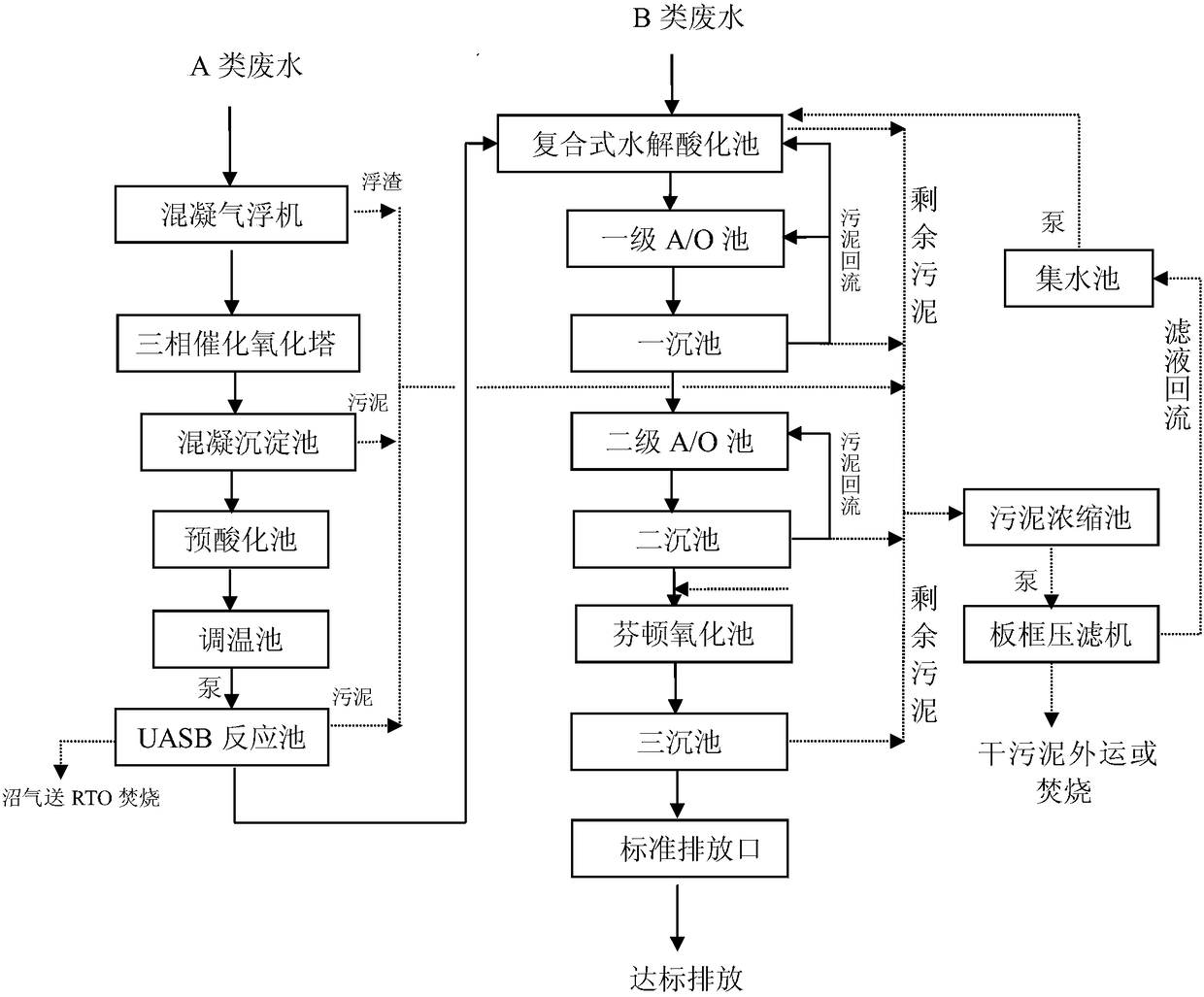

Image

Examples

Embodiment 1

[0023] (1) Wastewater quality and quantity

[0024] 1. Design water volume: Q=3600m 3 / d

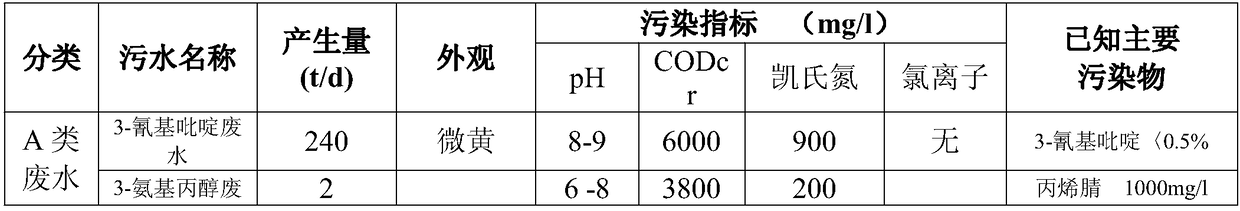

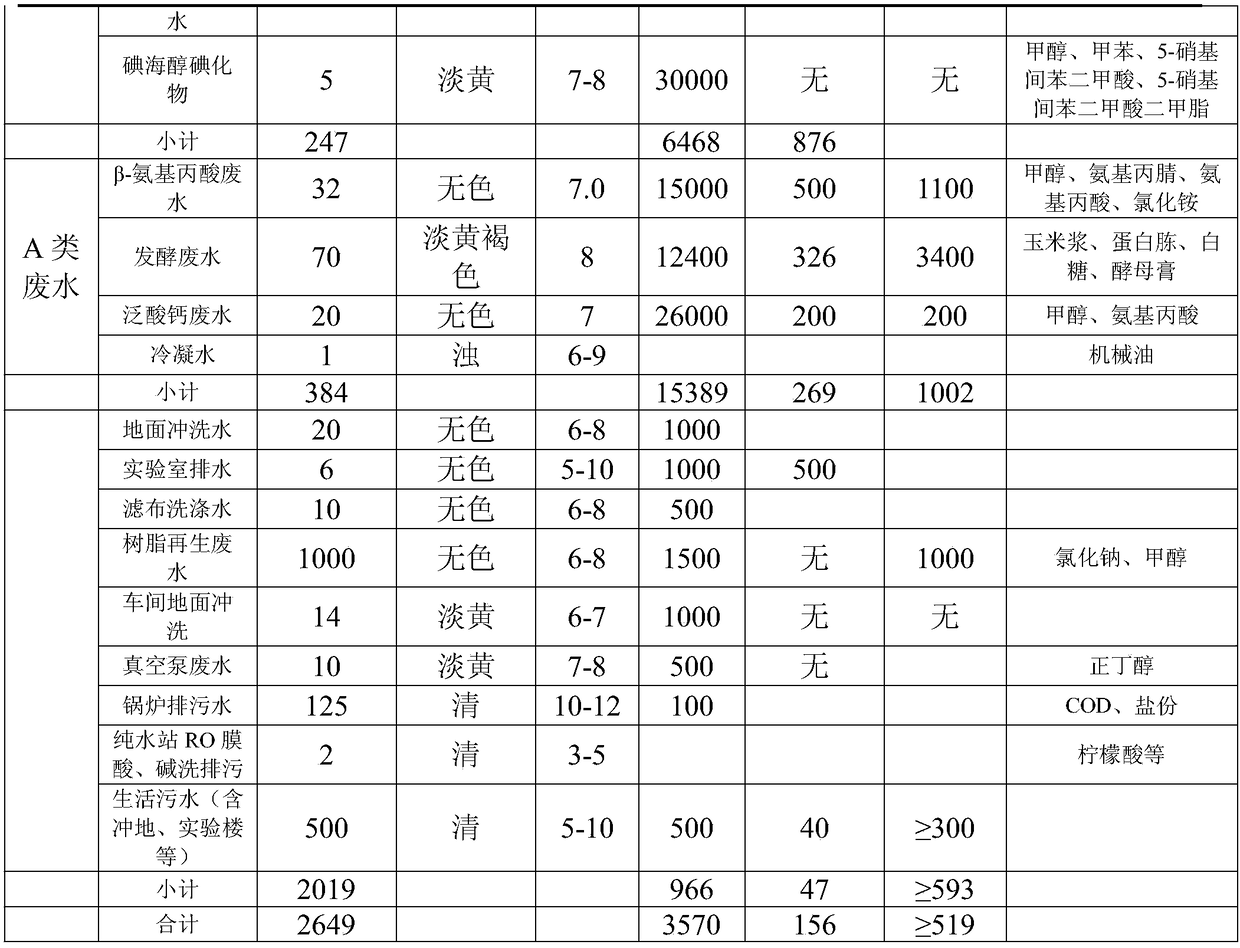

[0025] 2. Influent water quality is shown in Table 1

[0026] Table 1 Influent water quality

[0027]

[0028]

[0029] (2) A kind of medical wastewater treatment process, the specific influent water quality is as shown in table 1, specifically comprises the following steps:

[0030] Step 1, pretreatment: one of the 3-cyanopyridine wastewater, 3-aminopropanol wastewater, iohexol iodide wastewater, β-alanine wastewater, fermentation wastewater, calcium pantothenate wastewater and condensed water that needs to be treated Or any combination of Class A wastewater is mixed and pumped into the coagulation air flotation machine, and PAC and PAM are added to the water inlet pipeline through the coagulation dosing system. The mass ratio of PAC and PAM is 3:1. To remove grease, colloid and suspended solids, to ensure the stable operation of subsequent process facilities, the operating pa...

Embodiment 2

[0036] A medical wastewater treatment process, the specific influent water quality is shown in Table 1, specifically comprising the following steps:

[0037]Step 1, pretreatment: one of the 3-cyanopyridine wastewater, 3-aminopropanol wastewater, iohexol iodide wastewater, β-alanine wastewater, fermentation wastewater, calcium pantothenate wastewater and condensed water that needs to be treated Or any combination of Class A wastewater is mixed and pumped into the coagulation air flotation machine, and PAC and PAM are added to the water inlet pipeline through the coagulation dosing system. The mass ratio of PAC and PAM is 3:1. To remove grease, colloid and suspended solids, to ensure the stable operation of subsequent process facilities, the operating parameters of the coagulation air flotation machine are the operating load of 30m 3 / h, the flow rate of the dissolved air pump is 12.5m 3 / h, the reflux ratio of dissolved air pump water to air flotation inlet water is 40%, the p...

Embodiment 3

[0044] A medical wastewater treatment process, the specific influent water quality is shown in Table 1, specifically comprising the following steps:

[0045] Step 1, pretreatment: one of the 3-cyanopyridine wastewater, 3-aminopropanol wastewater, iohexol iodide wastewater, β-alanine wastewater, fermentation wastewater, calcium pantothenate wastewater and condensed water that needs to be treated Or any combination of Class A wastewater is mixed and pumped into the coagulation air flotation machine, and PAC and PAM are added to the water inlet pipeline through the coagulation dosing system. The mass ratio of PAC and PAM is 3:1. To remove grease, colloid and suspended solids, to ensure the stable operation of subsequent process facilities, the operating parameters of the coagulation air flotation machine are the operating load of 30m 3 / h, the flow rate of the dissolved air pump is 12.5m 3 / h, the water volume of the dissolved air pump and the reflux ratio of the air flotation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com