Method for preparing FexPO4-containing substances from ferrophosphorus at low temperature

A material, the technology of ferrophosphorus, which is applied in the field of low-temperature preparation of FexPO4-containing substances from ferrophosphorus, can solve the problems of large influence on product particle size, high water consumption, and high energy consumption, and achieve the elimination of slow gas-solid reaction speed and energy consumption High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

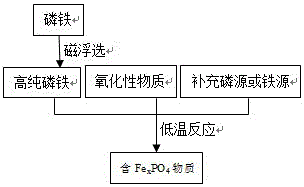

[0023] Ferrophosphorus Fe by solvothermal method 1.5 Preparation of Iron Hydroxyphosphate Fe from P 5 (PO 4 ) 4 (OH) 3 , the ferrophosphate slag Fe 1.5 P is crushed until the particle size is above 400 mesh. According to the magnetic difference between ferrophosphorus and impurities, the high-purity ferrophosphorus is transferred into a clean container by magnetic flotation, thereby improving the purity of the raw material ferrophosphorus. In the hydrothermal kettle with pressure valve, add phosphoric acid and hydrogen peroxide in proportion, and add water or other solvents as needed, and react at 50ºC to 300ºC for 5 to 75 hours to obtain Fe 5 (PO 4 ) 4 (OH) 3 Aqueous solution, the morphology and particle size of the product are controlled through the concentration process, and spherical Fe with a particle size of 20-30 nm can be obtained after drying. 5 (PO 4 ) 4 (OH) 3 finished product, process such as figure 1 Shown, the XRD of product is as figure 2 shown. T...

Embodiment 2

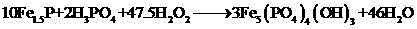

[0027] Using an external magnetic field to strengthen the transfer process and reaction process, made of phosphorus iron Fe 2 Preparation of iron phosphate FePO from P 4 , the iron phosphorus Fe 2 P is crushed until the particle size is above 1000 mesh, and then mixed with supplementary phosphorus source P 2 o 5 The powder is mixed evenly in proportion in a dry atmosphere, and then transferred into a closed heating container with a pressure reducing valve, and a certain amount of air is introduced to make the powder reach a boiling state, and an external magnetic field of 1T~10T is used to strengthen the ferrophosphorus powder in the reaction container. The transfer process and reaction in , react at 100ºC ~ 500ºC for 10 ~ 35 h, get FePO 4 finished product. The reaction equation is as follows:

[0028]

[0029] In this reaction, P 2 o 5 To supplement the phosphorus source, O in the air 2 As an oxidant, the product is only iron phosphate FePO 4 , no other by-product...

Embodiment 3

[0031] Preparation of iron phosphate FePO from iron phosphorus FeP by plasma method 4 , the plasma generator is composed of aluminized stainless steel as the anode, the stainless steel tank wall as the cathode, and distilled water as the electrolyte. Put iron phosphorus FeP into a titanium basket and place it in the anode area where the plasma is generated for oxidation for 0.5~5 h , regulate the voltage and current of the plasma power supply to regulate the composition of oxidation products, adjust the composition of the solution to regulate the solubility of phosphate oxidation products, use the solubility of phosphate to purify the products, adjust the particle size and shape by concentration, and dry FePO 4 finished product. In addition, ferrophosphorus can be modified by in-situ doping by adjusting the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com