A kind of ultrasonic-assisted preparation spherical praziquantel crystal and method

An ultrasound-assisted, praziquantel technology, applied in the direction of organic chemistry, organic chemistry, and resistance to vector-borne diseases, can solve problems such as difficult effects and product purity, and achieve cost savings, uniform crystal shape, and fluidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

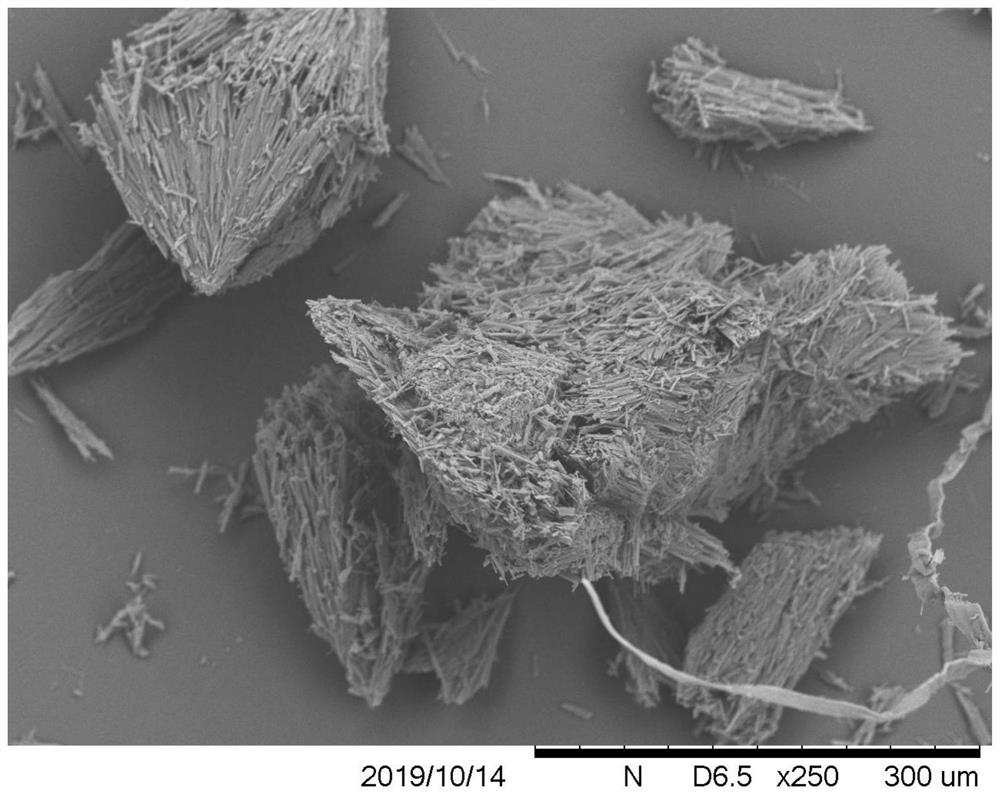

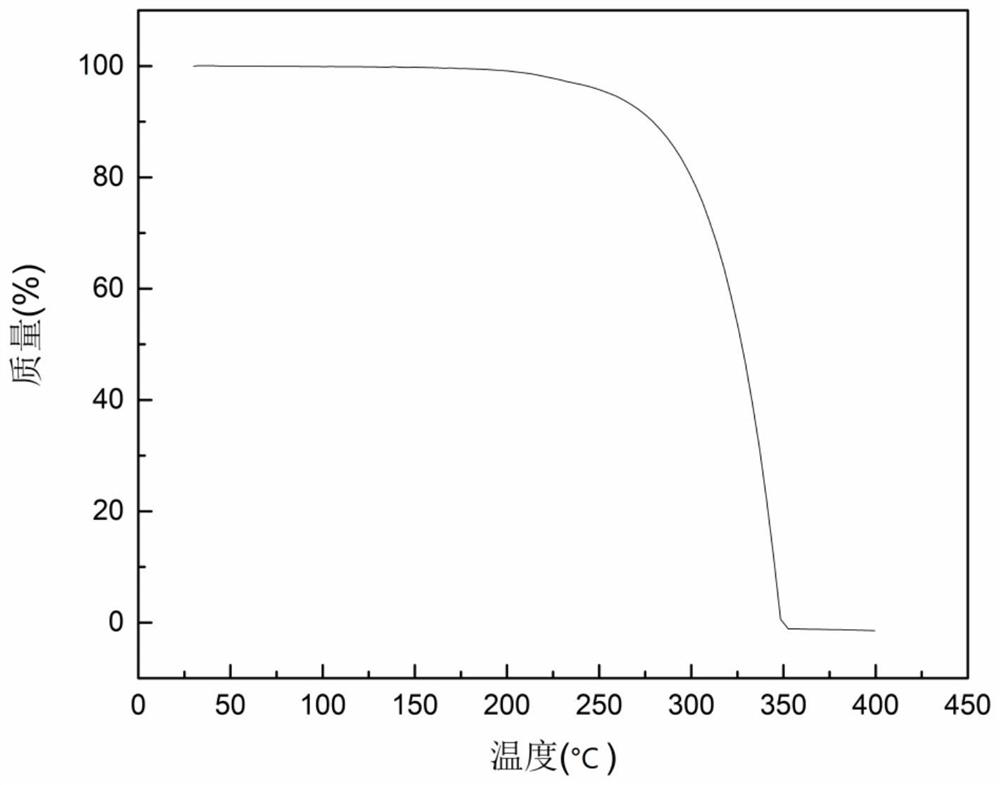

Embodiment 1

[0046]Add 25.5g of praziquantel to 100.0g of isopropanol solution, start stirring, the stirring rate is 50rpm, the system temperature is 50°C, adopt the cooling crystallization method, cool down at 10°C / h, and insert the ultrasonic probe when the temperature drops to 30°C , set the ultrasonic power to 100W, and the ultrasonic time to 5min. During the ultrasonic process, crystals will be precipitated in the system. After maintaining the crystal for 30min, continue to cool down at 30°C / h until the temperature is lowered to 0°C, and keep warm for 30min. Then filter, wash with ice isopropanol (0° C.), and dry at 50° C. under normal pressure for 3 hours to constant weight to obtain praziquantel spherical crystal product. The mass fraction of crystals within the particle size range of 1 mm to 3 mm is 90.9%, the roundness value of the praziquantel spherical product is 0.94, the angle of repose is 7°, and the caking rate is 2.32%.

Embodiment 2

[0048] Add 25.5g of praziquantel to 100.0g of isopropanol solution, start stirring, the stirring rate is 50rpm, the system temperature is 50°C, adopt the cooling crystallization method, cool down at 10°C / h, and insert the ultrasonic probe when the temperature drops to 30°C , set the ultrasonic power to 100W, and the ultrasonic time to 5min. During the ultrasonic process, crystals will be precipitated in the system. After maintaining the crystal for 30min, continue to cool down at 30°C / h until the temperature is lowered to 0°C, and keep warm for 30min. Then filter, wash with ice isopropanol (0° C.), and dry at 50° C. under normal pressure for 3 hours to constant weight to obtain praziquantel spherical crystal product. The mass fraction of crystals within the particle size range of 1 mm to 3 mm is 91.7%, the roundness value of the praziquantel spherical product is 0.94, the angle of repose is 8°, and the caking rate is 2.98%.

Embodiment 3

[0050] Add 30.0g of praziquantel to 100.0g of isopropanol solution, start stirring, the stirring rate is 100rpm, the system temperature is 60°C, adopt the cooling crystallization method, cool down at 10°C / h, insert the ultrasonic probe when the temperature drops to 37.5°C , set the ultrasonic power to 100W, and the ultrasonic time to 5min. During the ultrasonic process, crystals will be precipitated in the system. After maintaining the crystal for 30min, continue to cool down at 20°C / h until the temperature is lowered to 0°C, and keep warm for 30min. Then filter, wash with ice isopropanol (0° C.), and dry at 50° C. under normal pressure for 3 hours to constant weight to obtain praziquantel spherical crystal product. The mass fraction of crystals within the particle size range of 1 mm to 3 mm is 92.9%, the roundness value of the praziquantel spherical product is 0.91, the angle of repose is 6°, and the caking rate is 3.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com