Preparation method for monodisperse spherical silver powder

A monodisperse, silver powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of process complexity and impurity residue, and achieve the effect of simple operation, less residue and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

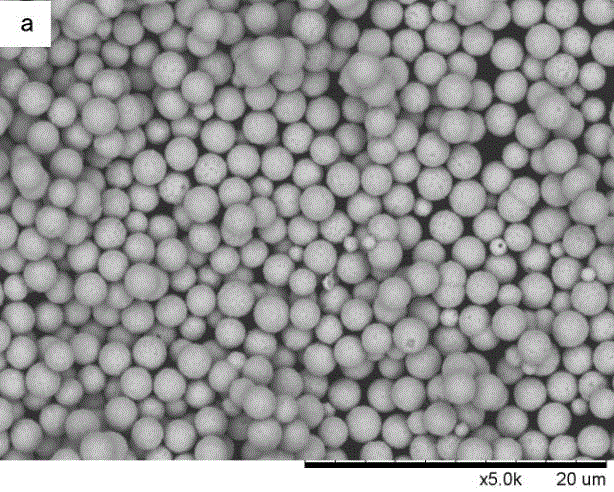

[0024] Embodiment 1: prepare and add 80g silver nitrate in a 1 liter container, dissolve with deionized water, make the concentration of silver nitrate solution reach 100g / L. Add 50 g of ascorbic acid to another 2 liter container and dissolve with deionized water. Then add 0.5g chitosan (molecular weight 20kDa), 2.5g potassium hydrogen phthalate, stir to dissolve, add 0.1g sulfuric acid, then adjust the acidity with 45g nitric acid (mass fraction 65%), and finally add water to make 1 liter of mixture.

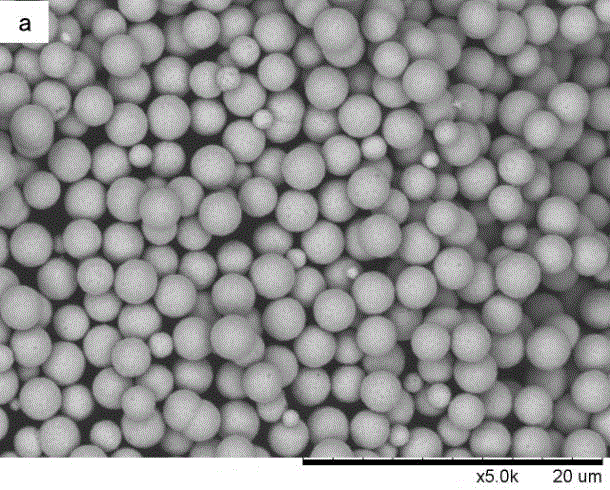

[0025] Heat the above two solutions to 40°C, stir for 30 minutes, quickly pour the silver nitrate solution into the reducing agent mixed solution without stirring, and keep it for 30 minutes, then filter the settled silver powder, wash it with water 4 times, and remove it with absolute ethanol. Wash twice, and dry at 50°C for 12 hours to obtain monodisperse spherical silver powder. The particle size distribution is between 1.0 micron and 4.0 micron, and the concentration is b...

Embodiment 2

[0026] Embodiment 2: prepare and add 80g silver nitrate in a 1 liter container, dissolve with deionized water, make the concentration of silver nitrate solution reach 160g / L. Add 50 g of ascorbic acid to another 2 liter container and dissolve with deionized water. Then add 1.0g chitosan (molecular weight 30kDa), 2.0g potassium hydrogen phthalate, stir to dissolve, add 0.1g sulfuric acid, then add 45g nitric acid (mass fraction 65%) to adjust the acidity, add water to make 1 liter mixture.

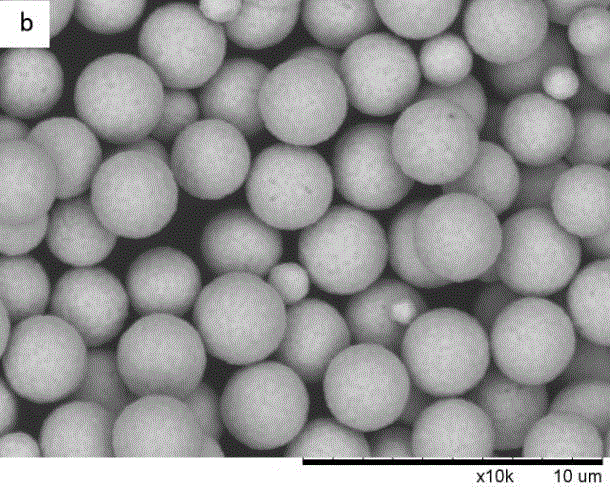

[0027] Heat the above two solutions to 50°C, and after stirring for 30 minutes, quickly pour the silver nitrate solution into the reducing agent mixed solution without stirring. Wash twice, and dry at 50°C for 12 hours to obtain the monodisperse spherical silver powder, with a particle size distribution of 1.0 micron to 4.0 micron, mainly concentrated in 2.0 micron to 3.0 micron, see Figure 3 to Figure 4 .

Embodiment 3

[0029] Embodiment 3: acid silver solution concentration 80g / L, ascorbic acid addition 40g, chitosan addition 0.5g (molecular weight 10kDa), potassium hydrogen phthalate addition 4g, sulfuric acid addition 0.5g, nitric acid addition (mass Fraction 65%) 40g, reaction temperature 60 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com