Metal additive preparation method for curved-surface thin shell structure

A metal additive, layer structure technology, applied in the direction of additive processing, additive manufacturing, energy efficiency improvement, etc., to achieve the effect of improving corrosion resistance and fatigue resistance, high operating efficiency, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

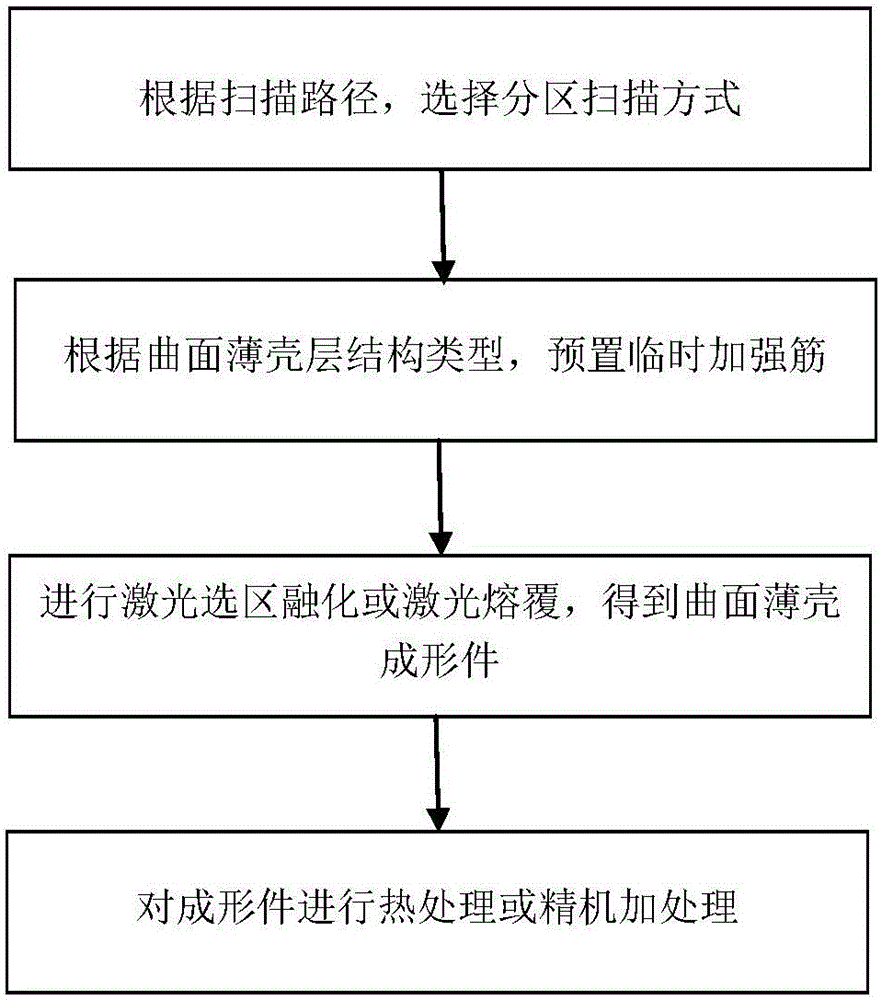

[0023] Attached below figure 1 The specific steps of a metal additive manufacturing method with a curved surface and thin shell structure of the present invention are described in detail.

[0024] A method for preparing a metal additive material with a curved surface thin shell structure, characterized in that the preparation method comprises the following steps:

[0025] 1) According to the surface parameter equation of the curved surface thin shell structure, the characteristic analysis of the surface set is carried out to obtain the scanning path during laser selective melting or laser cladding, and the mobile scanning method is determined to be the partition mobile scanning method. During the forming process of layer-by-layer additive manufacturing In , control the process parameters of the laser to scan the boundary contour of the surface layer and each partition. The shape of each partition is square, rectangular or circular, and the scanning method is skip or continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com