Preparation method and application of titanium dioxide nanocomposite particles loaded with pt-au alloy

A nanocomposite, pt-au technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as limiting the development of catalytic materials , to achieve the effect of preventing sintering and agglomeration and improving the catalytic oxidation performance of CO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1%Au / TiO 2 Preparation of composite nanoparticles and CO oxidation performance:

[0033] (1) Preparation of precursor solution: Weigh 0.05mol tetrabutyl titanate and dissolve it in 70ml xylene, then add 20.8ml 0.02mol / L chloroauric acid alcohol solution, then add 9.2ml ethanol, the xylene / L The volume ratio of ethanol was 7 / 3, and the mixed solution was sonicated for 20 minutes to obtain a precursor solution for use.

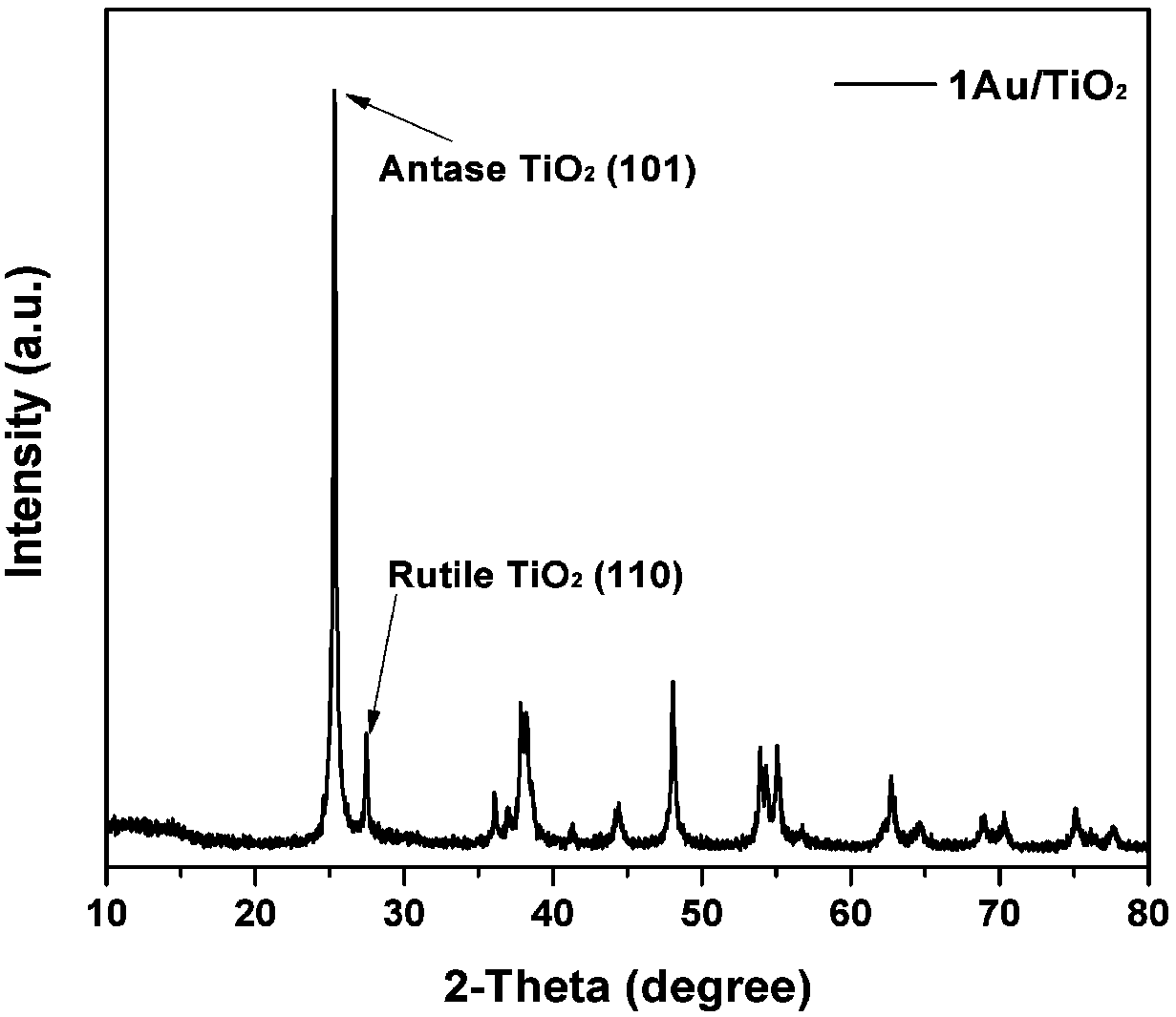

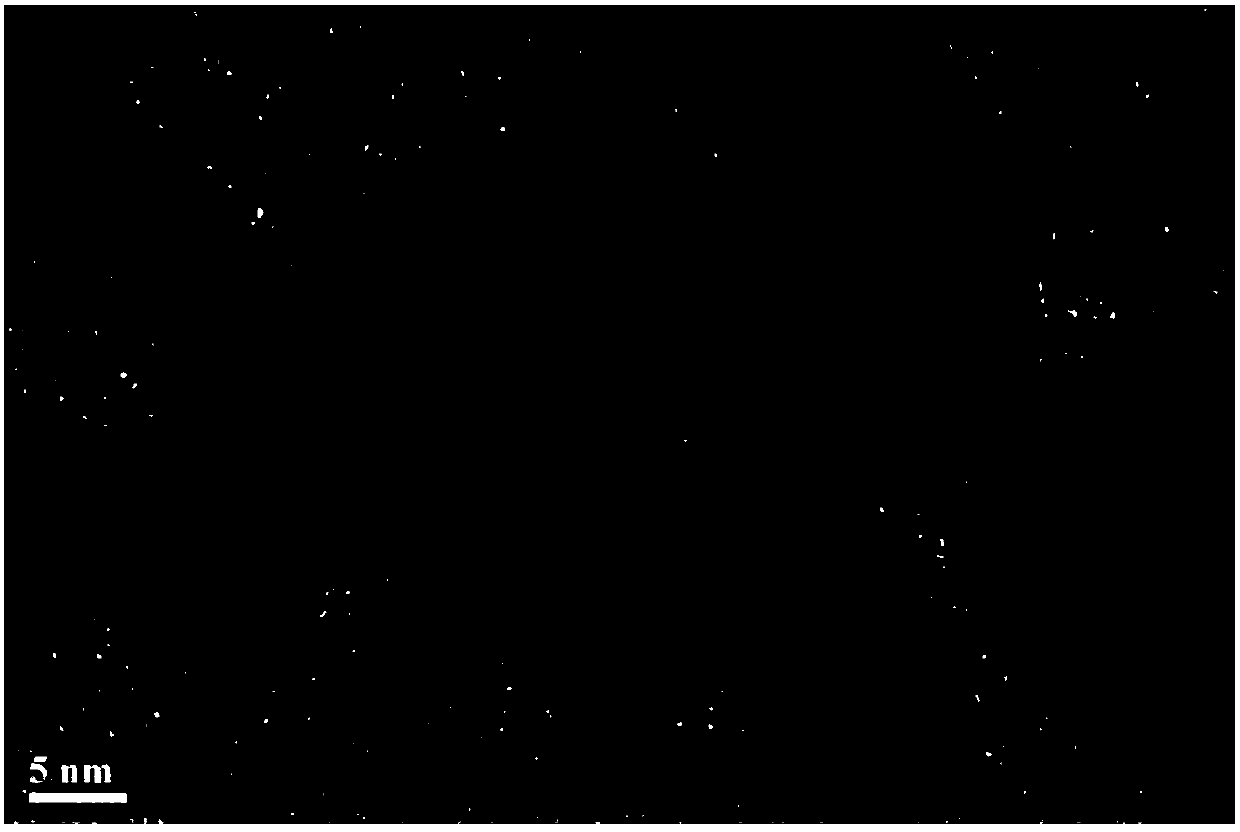

[0034] (2) Use a syringe pump to send the precursor solution to the reactor at a certain speed of 5mL / min through the atomization burner to form fine atomized droplets, and the shear pressure is 0.12MPa. 2 / O 2 (H 2 Flow 0.1m 3 / h,O 2 Flow 1.0m 3 / h) Combustion, pyrolysis, oxidation and other reactions occur under the assistance of a diffusion flame. After leaving the flame, the mixed-phase nano-TiO is collected by a vacuum pump-assisted glass fiber filter membrane. 2 Nanocomposite particles loaded with Au alloy, figure 1 XRD curves show that the ...

Embodiment 2

[0037] 0.75% Au-0.25% Pt / TiO 2 Preparation of composite nanoparticles and CO oxidation performance:

[0038] (1) Preparation of precursor solution: Weigh 0.05mol tetrabutyl titanate and butyl titanate as combined titanium source (ratio 2:1) and dissolve in 70ml xylene, then add 15.6ml 0.02mol / L chlorine Auric acid alcohol solution and 6.25ml 0.02mol / L chloroplatinic acid alcohol solution, then add 8.2ml ethanol, the xylene / ethanol volume ratio in the system is about 7 / 3, after the mixed solution is ultrasonicated for 20min, the precursor solution is obtained. use.

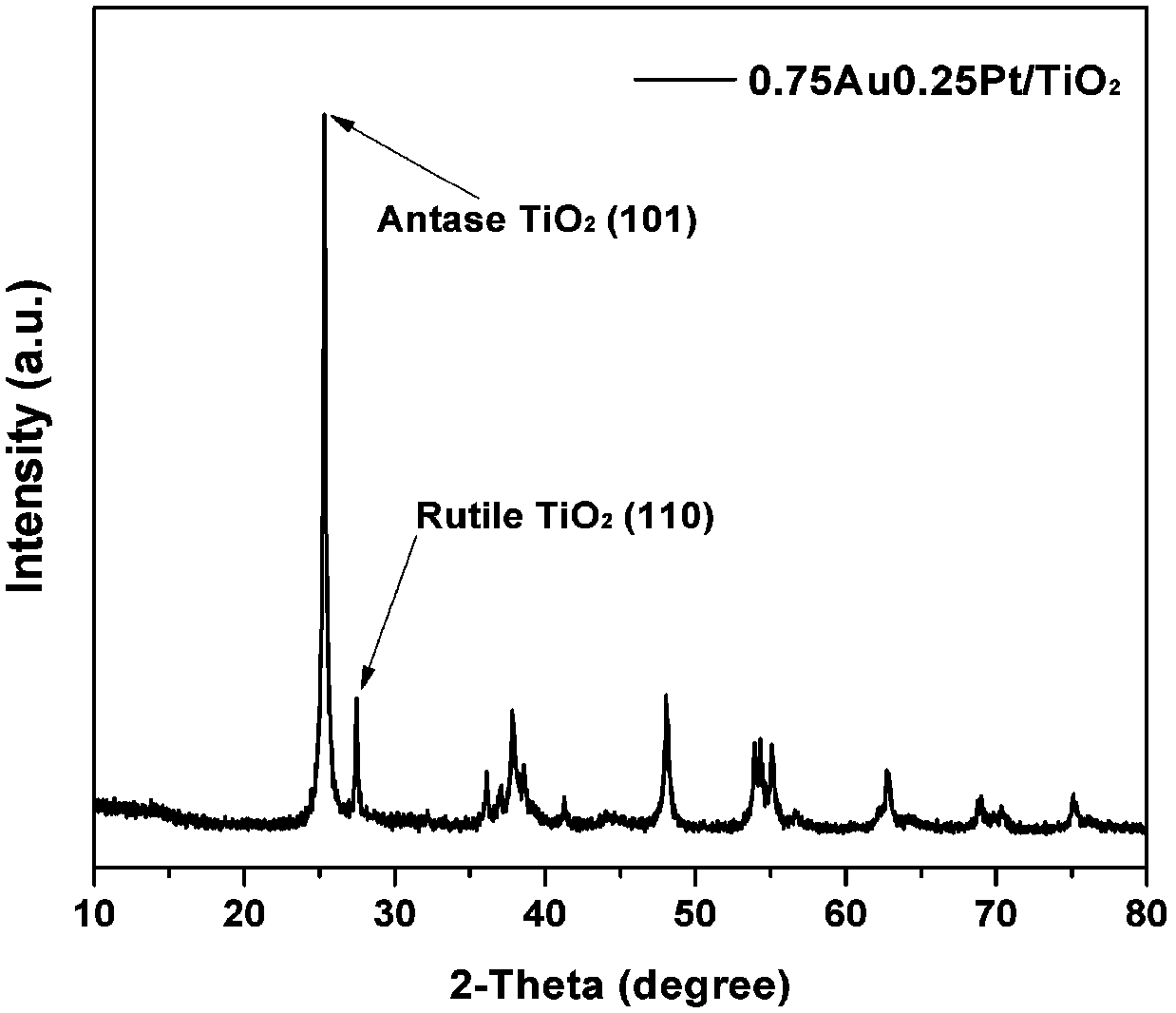

[0039] (2) Use a syringe pump to send the precursor solution to the reactor at a certain speed of 3mL / min through the atomization burner to form fine atomized droplets, and the shear pressure is 0.15MPa. 2 / O 2 (H 2 Flow 0.15m 3 / h,O 2 Flow 1.0m 3 / h) Combustion, pyrolysis, oxidation and other reactions occur under the assistance of a diffusion flame. After leaving the flame, the mixed-phase nano-TiO is coll...

Embodiment 3

[0042] 0.25% Au-0.75% Pt / TiO 2 Preparation of composite nanoparticles and CO oxidation performance:

[0043] (1) Preparation of precursor solution: Weigh 0.05mol butyl titanate as a titanium source and dissolve it in 70ml xylene, then add 5.3ml 0.02mol / L chloroauric acid alcohol solution and 18.8ml 0.02mol / L platinum chloride Acid-alcohol solution, then add 5.9ml of ethanol, the xylene / ethanol volume ratio in the system is about 7 / 3, and the mixed solution is ultrasonicated for 20 minutes to obtain a precursor solution, which is ready for use.

[0044] (2) Use a syringe pump to send the precursor solution to the reactor at a certain speed of 5mL / min through the atomization burner to form fine atomized droplets, and the shear pressure is 0.2MPa. 2 / O 2 (H 2 Flow 0.1m 3 / h,O 2 Flow 1.0m 3 / h) Combustion, pyrolysis, oxidation and other reactions occur under the assistance of a diffusion flame. After leaving the flame, the mixed-phase nano-TiO is collected by a vacuum pump-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com