Molybdenum trioxide-coated molybdenum-doped titanium dioxide nanocomposite particles and its preparation method and application

A technology of titanium dioxide and molybdenum trioxide, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as the influence of electrochemical properties of materials, and achieve high electrochemical activity and high rate performance, The effect of increasing specific capacity and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

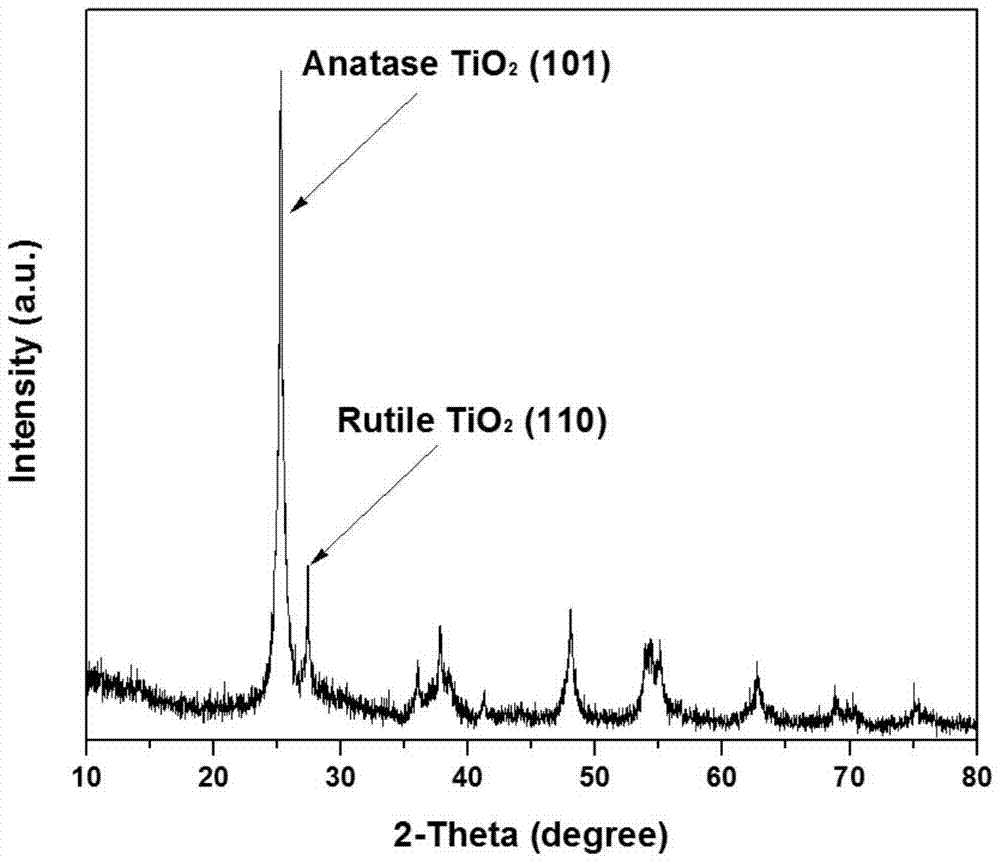

Embodiment 1

[0036] 5%Mo / TiO 2 Preparation of composite nanoparticles and their application in lithium batteries:

[0037] (1) Preparation of precursor solution: 12.93g of tetrabutyl titanate and 0.65g of molybdenum acetylacetonate were ultrasonically dissolved in 100mL of xylene to obtain a 0.4M (titanium source) precursor solution for use.

[0038] (2) Use a syringe pump to form fine atomized droplets through an external gas-assisted shear (shear pressure 0.12MPa) atomization burner at a certain speed of 5mL / min. h 2 / O 2 (H 2 Flow 0.1m 3 / h,O 2 Flow 1.0m 3 / h) Combustion, pyrolysis, oxidation and other reactions occur under the assistance of the diffusion flame. After leaving the flame, the vacuum pump assists the glass fiber filter to collect the molybdenum trioxide-coated molybdenum-doped titanium dioxide nanocomposite particles.

[0039] (3) Calcining the obtained nano-powder in an air atmosphere, the heating rate is 1°C / min, the calcination temperature is 350°C, and the calci...

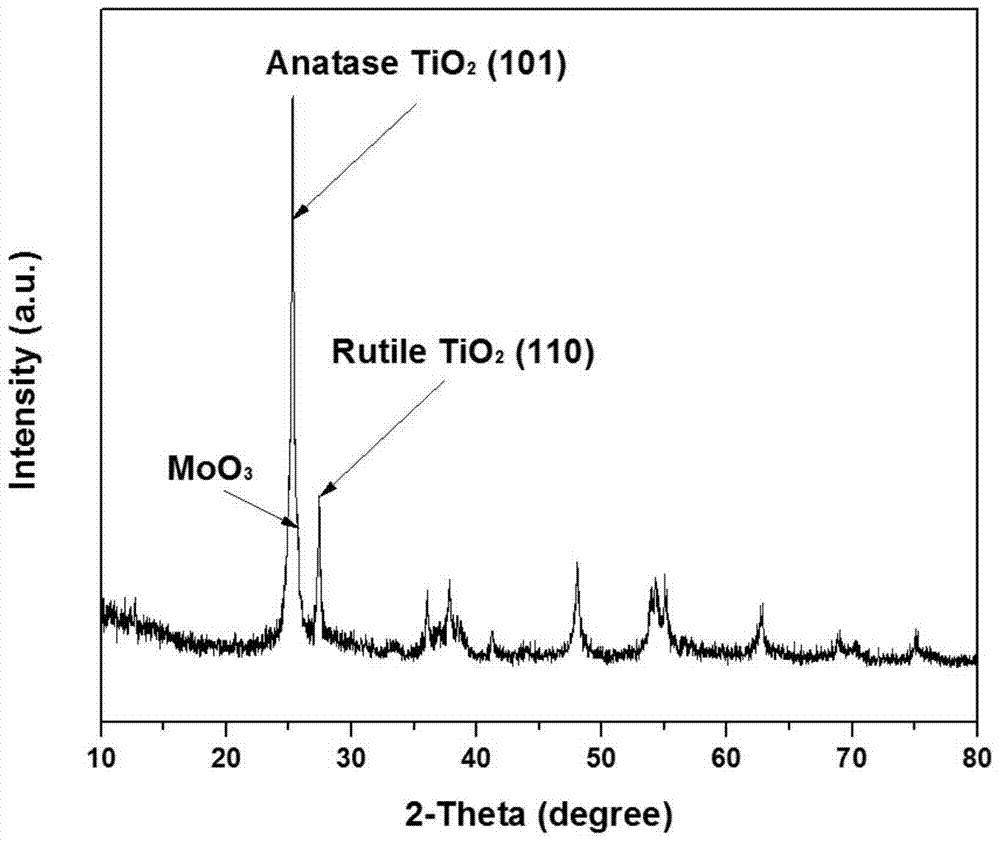

Embodiment 2

[0042] 10%Mo / TiO 2 Preparation of composite nanoparticles and their application in lithium batteries:

[0043] (1) Preparation of precursor solution: Weigh 10.01g of tetrabutyl titanate and 2.25g of butyl titanate as a combined titanium source, dissolve them in 100mL of toluene / xylene (volume ratio of 1:1), a 0.4M (titanium source) precursor solution was obtained for use.

[0044] (2) Use a syringe pump to form fine atomized droplets through an external gas-assisted shear (shear pressure 0.15MPa) atomization burner at a certain speed of 5mL / min. h 2 / O 2 (H 2 Flow 0.15m 3 / h,O 2 Flow 1.0m 3 / h) Combustion, pyrolysis, oxidation and other reactions occur under the assistance of the diffusion flame. After leaving the flame, the vacuum pump assists the glass fiber filter to collect the molybdenum trioxide-coated molybdenum-doped titanium dioxide nanocomposite particles.

[0045] (3) Calcining the obtained nano-powder in an air atmosphere, the heating rate is 2°C / min, the c...

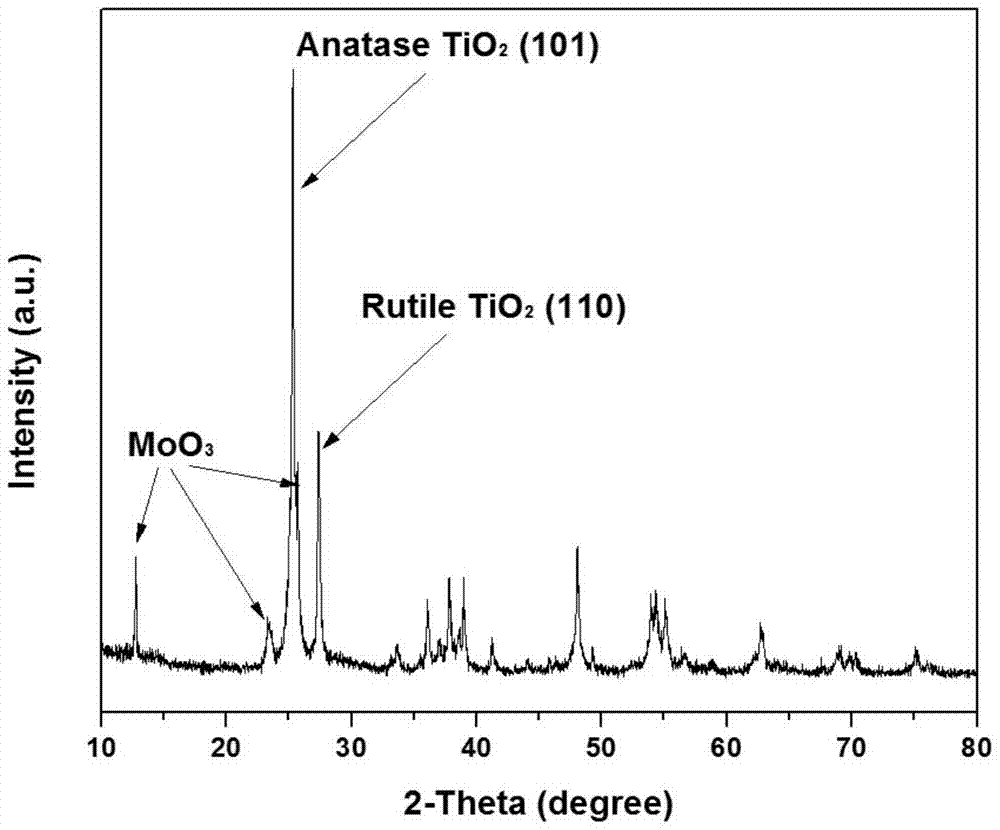

Embodiment 3

[0048] 15%Mo / TiO 2 Preparation of composite nanoparticles and their application in lithium batteries:

[0049] (1) Preparation of precursor solution: 14.46g of butyl titanate and 2.45g of molybdenum acetylacetonate were weighed and dissolved in 100mL of toluene by ultrasonication for 20min to obtain a 0.5M (titanium source) precursor solution for use.

[0050] (2) Use a syringe pump to form fine atomized droplets through an external gas-assisted shear (shear pressure 0.2MPa) atomization burner at a certain speed of 6mL / min. h 2 / O 2 (H 2 Flow 0.1m 3 / h,O 2 Flow 1.2m 3 / h) Combustion, pyrolysis, oxidation and other reactions occur under the assistance of the diffusion flame. After leaving the flame, the vacuum pump assists the glass fiber filter to collect the molybdenum trioxide-coated molybdenum-doped titanium dioxide nanocomposite particles.

[0051] (3) Calcining the obtained nano-powder in an air atmosphere, the heating rate is 1°C / min, the calcination temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com