A kind of heavy oil processing technology and processing device

A processing technology, heavy oil technology, applied in the petroleum industry, hydrocarbon oil treatment, catalytic cracking, etc., can solve the problems of low utilization rate and low yield of petroleum resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

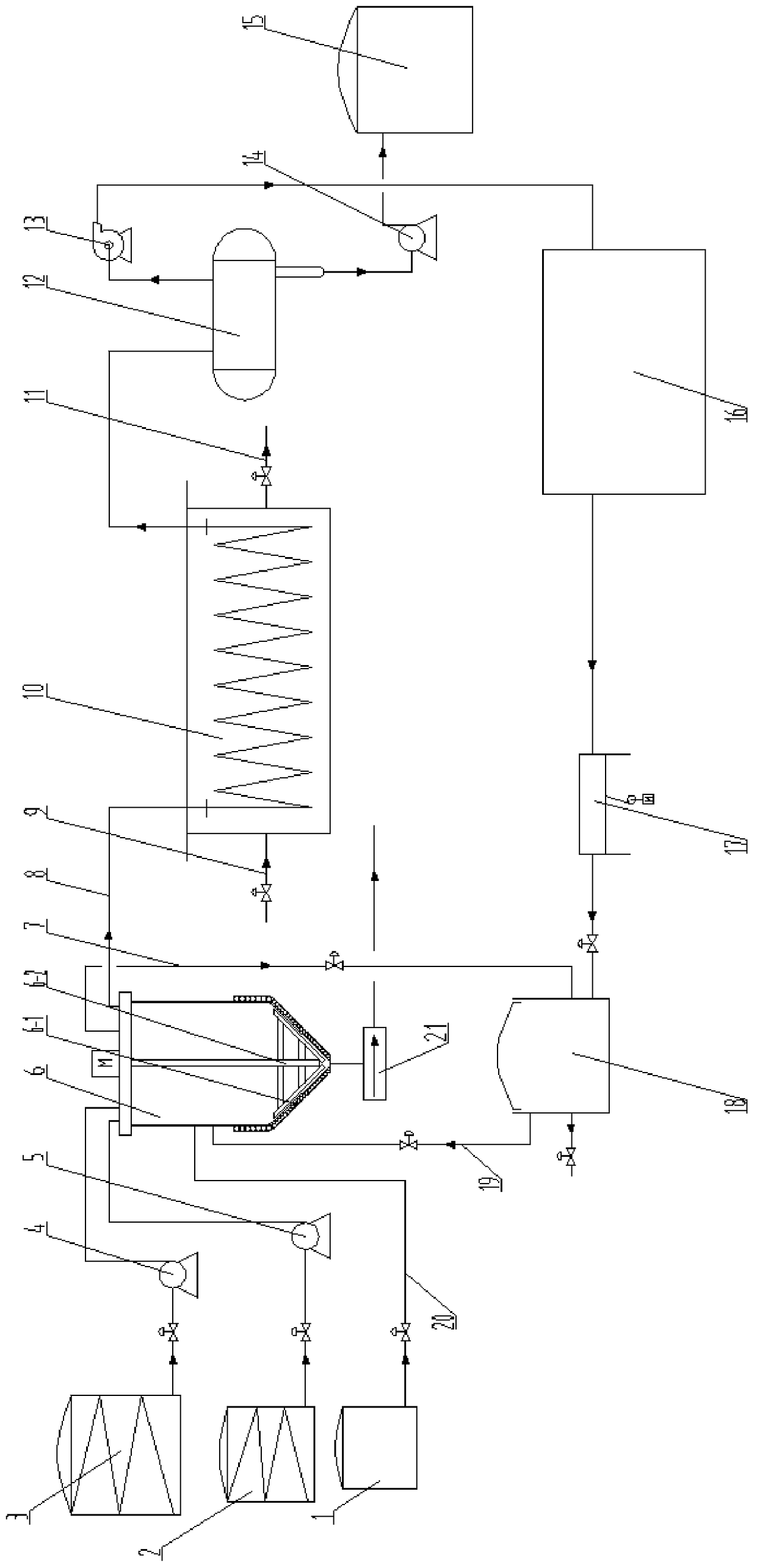

[0071] use figure 1 The processing unit shown processes heavy oil:

[0072] Preheat the materials inside the heavy oil tank 3 and the catalyst tank 2 to 50°C, and pump the two into the reactor 6 at a mass ratio of 98:2. Start the heating device 6-1 and the mechanical decoking device 6-2 to heat and stir respectively, and the material starts to undergo low-temperature catalytic carbonization reaction. When the temperature in the reactor 6 rises to 300°C, lift the mechanical decoking device 6-2 to above the liquid level and close it. When the material inside the reactor 6 is heated to 420°C, the heating device 6-1 is turned off, the entire low-temperature catalytic carbonization time lasts for 2 hours, the tank top gauge pressure is -0.5KPa, and the generated high-temperature oil gas escapes and into the condenser 10. Open the cold glycol circulating water supply pipeline 9 and the cold glycol circulating water return pipeline 11, exchange heat with the high-temperature oil a...

Embodiment 2

[0075] use figure 1 The processing unit shown processes heavy oil:

[0076] Preheat the materials inside the heavy oil tank 3 and the catalyst tank 2 to 95°C, and pump the two into the reactor 6 at a mass ratio of 96:4. Start the heating device 6-1 and the mechanical decoking device 6-2 to heat and stir respectively, and the material starts to undergo low-temperature catalytic dry distillation reaction. When the temperature in the reactor 6 rises to 350°C, lift the mechanical stirring device 6 -2 to above the liquid level and close it. Turn off the heating device 6-1 until the material inside the reactor 6 is heated to 470°C, the entire low-temperature catalytic carbonization time lasts for 4 hours, the tank top gauge pressure is 1.5KPa, and the generated high-temperature oil gas escapes and enters condensation device 10. Open the cold ethylene glycol circulating water supply pipeline 9 and the cold ethylene glycol circulating water return pipeline 11 to exchange heat with ...

Embodiment 3

[0079] use figure 1 The processing unit shown processes heavy oil:

[0080] Preheat the materials inside the heavy oil tank 3 and the catalyst tank 2 to 70°C, and pump the two into the reactor 6 at a mass ratio of 97:3. Start the heating device 6-1 and the mechanical decoking device 6-2 to heat and stir respectively, and the material starts to undergo low-temperature catalytic carbonization reaction. When the temperature in the reactor 6 rises to 315°C, lift the mechanical decoking device 6-2 to above the liquid level and close it. Turn off the heating device 6-1 until the material inside the reactor 6 is heated to 455°C, the entire low-temperature catalytic carbonization time lasts for 3 hours, the tank top gauge pressure is 1KPa, and the generated high-temperature oil gas escapes and enters the condenser within 10. Open the cold ethylene glycol circulating water supply pipeline 9 and the cold ethylene glycol circulating water return pipeline 11 to exchange heat with the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com