Aseptic collagen liquid with biological activity and preparation method thereof

A technology of biological activity and collagen solution, which is applied in the direction of medical preparations containing active ingredients, skin care preparations, drug combinations, etc., can solve the problems of reducing collagen antigenicity, difficult to realize the supply process, unstable process, etc., and achieve shortening Purification time, avoid denaturation and inactivation, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

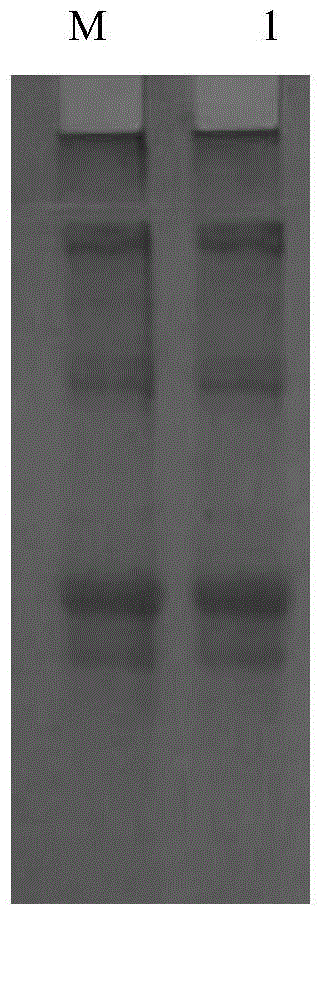

Image

Examples

preparation example Construction

[0033] A preparation method of a biologically active sterile collagen solution, comprising the steps of:

[0034] 1) Degrease, slice and sterilize the tendon of the animal;

[0035] 2) Pulverizing the above-mentioned sterilized tendons under ultra-low temperature conditions to obtain filamentous tendon fibers;

[0036] 3) The pulverized tendon tissue is acid-dissolved and enzymatically hydrolyzed, and then the slag is filtered to obtain the original collagen solution;

[0037] 4) The collagen stock solution is further salted out and purified to obtain a high-purity collagen solution;

[0038] 5) Fill the purified high-purity collagen solution in a clean environment of class 100,000 or above, subpackage and seal;

[0039] 6) Freeze the sealed high-purity collagen solution;

[0040] 7) Put the frozen collagen solution into a foam box or an incubator equipped with dry ice or an ultra-low temperature freezer, seal it, and sterilize it with low-temperature radiation. After thawi...

Embodiment 1

[0055] 1) Fresh healthy beef tendon, remove the fat and fascia, wash to remove impurities, freeze and slice, sterilize and save for later use

[0056] 2) Take the above-mentioned sterilized beef tendons and grind them at -80°C to -60°C to obtain filamentous tendon fibers;

[0057] 3) Add 100 times the volume of a mixture of 0.5mol / L glacial acetic acid and 400mg / L pepsin to the tendon fibers, and continue stirring for 3 hours. The ambient temperature range is 25-28°C, and the stirring speed is 50rpm;

[0058] The above mixed solution was filtered to remove slag to obtain the collagen stock solution;

[0059] 4) Add the above collagen stock solution to an equal volume of 1.4mol / L sodium chloride solution for salting out, take the precipitate, add 0.5mol / L glacial acetic acid to dissolve the precipitate, and purify it through ultrafiltration equipment, ultrafiltration system The conditions are: the pressure at the mouth end is 40psi, the return end is 10psi, and the high-purity c...

Embodiment 2

[0064] 1) Fresh healthy pork tendon, remove the fat and fascia, wash to remove impurities, freeze and slice, sterilize and save for later use

[0065] 2) Take the above-mentioned sterilized pork tendons and grind them at -150°C to -100°C to obtain filamentous tendon fibers;

[0066] 3) Add 150 times the volume of a mixture of 0.4mol / L glacial acetic acid and 300mg / L pepsin to the tendon fibers, and continue to stir for 10 hours. The ambient temperature range is 25-27°C, and the stirring speed is 10rpm;

[0067] The above-mentioned mixed solution is filtered through a 40-mesh filter screen to remove slag to obtain a collagen stock solution;

[0068] 4) Add the above collagen stock solution to an equal volume of 1.4mol / L sodium chloride solution for salting out, take the precipitate, add 0.4mol / L glacial acetic acid to dissolve the precipitate, and purify it through ultrafiltration equipment, ultrafiltration system The conditions are: the pressure at the mouth end is 10psi, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com