Switching power supply of macromolecular leather paint spraying dryer

A switching power supply and drying machine technology, applied in the electronic field, can solve problems such as output voltage and current instability, achieve the effects of improving load capacity, stable working performance, and preventing deformation or paint peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

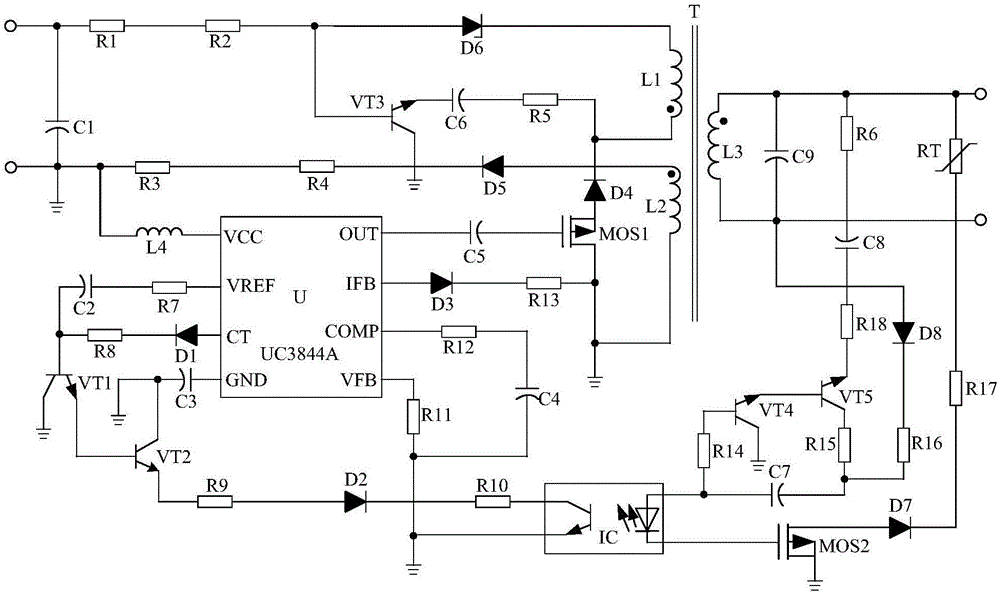

[0017] Such as figure 1 As shown, the present invention is mainly composed of a control chip U, a transformer T, a field effect transistor MOS1, a resistor R11, a resistor R12, a resistor R13, a polar capacitor C4, a polar capacitor C5, a diode D3, a current adjustment circuit, a photoelectric coupling switch circuit, and an overvoltage protection circuit.

[0018] When connected, the negative pole of the polarity capacitor C5 is connected to the gate of the field effect transistor MOS1, and its positive pole is connected to the OUT pin of the control chip U. The N pole of the diode D3 is connected to the drain of the field effect transistor MOS1 through the resistor R13, and its P pole is connected to the IFB pin of the control chip U. The positive pole of the polarity capacitor C4 is connected to the COMP pin of the control chip U through the resistor R12, and its negative pole is connected to the VFB pin of the control chip U through the resistor R11. The overvoltage prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com