A kind of method that magnetron sputtering prepares ceo2/ptfe/nafion composite film

A technology of magnetron sputtering and PTFE, which is applied in sputtering coating, electrochemical generator, vacuum evaporation coating, etc., can solve the problems of damaging the performance of proton exchange membrane battery and prone to fracture, etc., and achieves the benefit of casting composite , Improve hydrophilicity, reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] PTFE microporous membrane pretreatment: Flatten the PTFE microporous membrane with two A4 papers, put it under the flat paper cutter, cut into several 7×7cm PTFE microporous membranes, cut the cut PTFE microporous membranes The film was immersed in acetone solution, soaked in a fume hood for 20 hours, then soaked in 98% ethanol solution for 10 hours, after soaking for many times to remove acetone, washed with deionized water to remove ethanol, and finally dried at 60°C for 10 hours to obtain Cleaned PTFE microporous membrane.

[0029] Target pretreatment: the CeO 2 The target material was wiped several times with acetone, then wiped with 98% ethanol, dried, and placed in a magnetron sputtering coating machine.

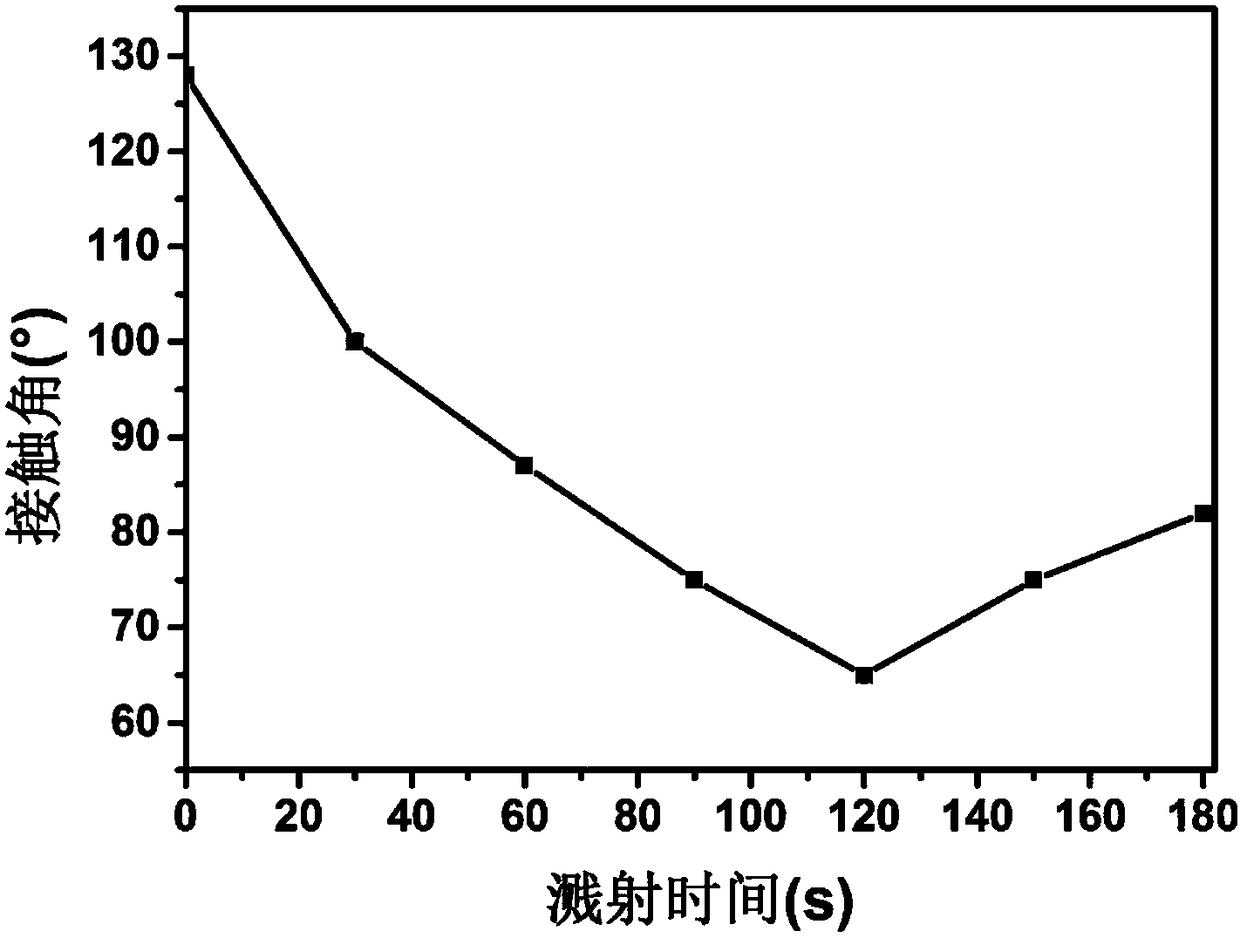

[0030] First put the pretreated PTFE microporous membrane in a magnetron sputtering coating machine, in an argon atmosphere, adjust the sputtering power to 60w, the sputtering pressure to 0.6Pa, and the sputtering time to 30s, 60s, 90s, 120s, 150s, 180s.

[0...

Embodiment 2

[0034] PTFE microporous membrane pretreatment: soak PTFE microporous membrane in acetone solution for 20 hours; then soak in 98% ethanol solution for 10 hours, after soaking for many times to remove acetone, wash with deionized water to remove ethanol; finally at 60°C Dry for 10 hours to obtain a cleaned PTFE microporous membrane.

[0035] Target pretreatment: the CeO 2 The target material was wiped several times with acetone, then wiped with 98% ethanol, dried, and placed in a magnetron sputtering coating machine.

[0036] Put the pretreated PTFE microporous membrane in a magnetron sputtering coating machine in an argon atmosphere, adjust the sputtering time to 120s, the sputtering pressure to 0.6Pa, and the sputtering power to 20w, 40w, 60w, and 80w respectively , 100w.

[0037] Casting Nafion resin: Mix dimethyl sulfoxide and 5% Nafion resin at a ratio of 3:1, put it in a rotary evaporator until the weight of the mixed solution is constant, cool to room temperature, and i...

Embodiment 3

[0040] PTFE microporous membrane pretreatment: soak PTFE microporous membrane in acetone solution for 20 hours; then soak in 98% ethanol solution for 10 hours, after soaking for many times to remove acetone, wash with deionized water to remove ethanol; finally at 60°C Dry for 10 hours to obtain a cleaned PTFE microporous membrane.

[0041] Target pretreatment: the CeO 2 The target material was wiped several times with acetone, then wiped with 98% ethanol, dried, and placed in a magnetron sputtering coating machine.

[0042] Put the pretreated PTFE microporous membrane in a magnetron sputtering coating machine, in an argon atmosphere, adjust the sputtering time to 120s, the sputtering pressure to 60W, and the sputtering pressure to 0.2Pa, 0.4Pa, 0.6Pa, 0.8Pa, 1.0Pa.

[0043] Casting Nafion resin: Mix dimethyl sulfoxide and 5% Nafion resin at a ratio of 3:1, put it in a rotary evaporator until the weight of the mixed solution is constant, cool to room temperature, and impregna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com