An electronic device and a method for making the curved glass

A technology for electronic equipment and curved surfaces, applied in the field of terminal production, can solve problems such as time-consuming, finished product defects, and inability to guarantee yield, so as to avoid time-consuming problems and improve yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

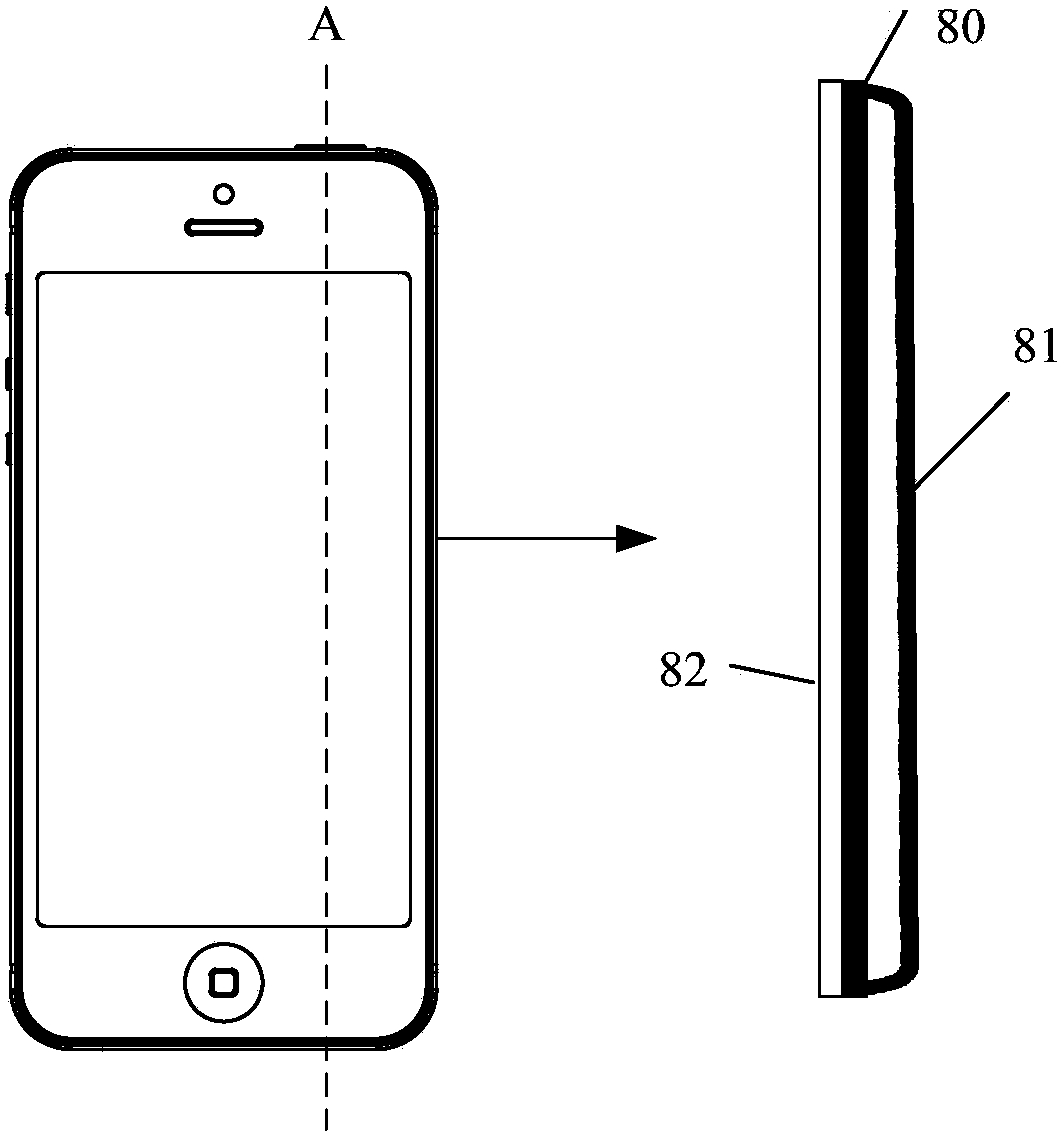

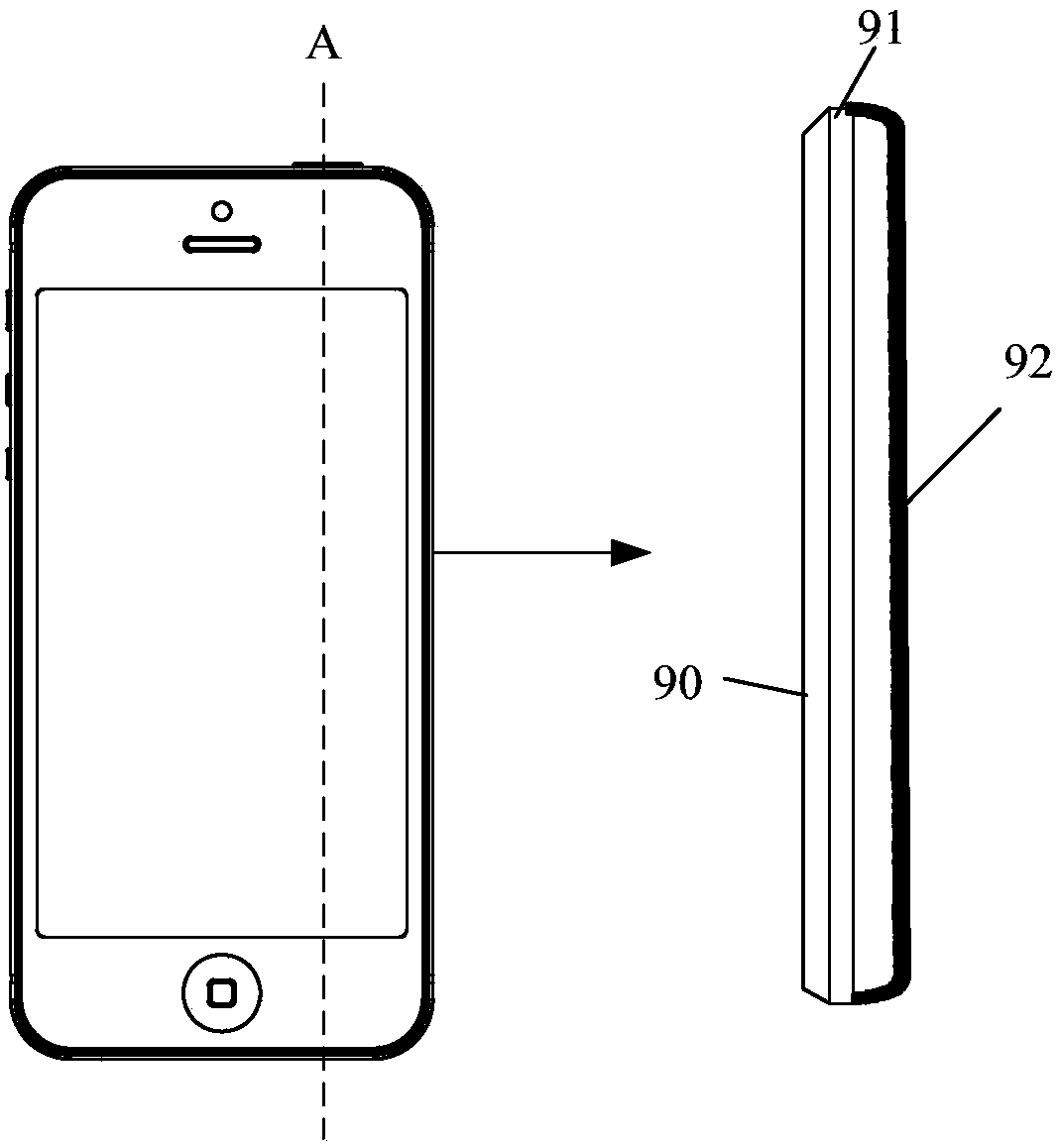

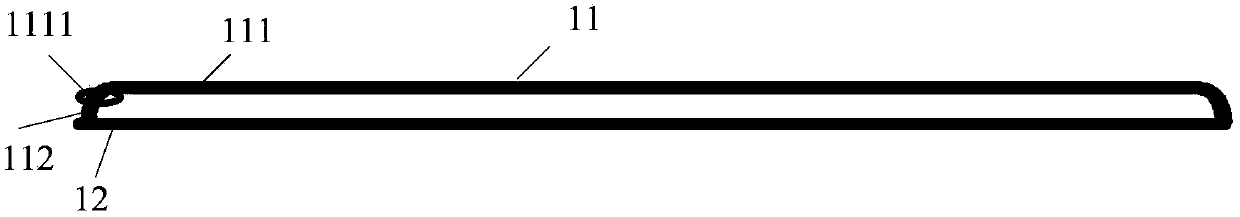

[0025] An embodiment of the present invention provides an electronic device, such as figure 1 As shown, it includes: a glass plate 11, the glass plate 11 is fixedly connected with the frame body 12 of the electronic device, at least part of the glass plate is a curved surface; the glass plate 11 includes: a first glass substrate 111 and a second glass plate Two glass substrates 112, wherein,

[0026] The first glass substrate 111 is located on the second glass substrate 112, and the first glass substrate 111 and the second glass substrate 112 are closely attached; wherein, the first part 1111 of the first glass substrate 111 is a curved surface to form the curved surface of the glass sheet.

[0027] The frame body may be the casing of the electronic device, or the middle frame body of the electronic device, for example, figure 1 The frame body 12 shown in may be only a middle frame body.

[0028] The manner in which the first part 1111 of the first glass substrate 111 is cl...

Embodiment 2

[0042] An embodiment of the present invention provides an electronic device, such as figure 1 As shown, it includes: a glass plate 11, the glass plate 11 is fixedly connected with the frame body 12 of the electronic device, at least part of the glass plate is a curved surface; the glass plate 11 includes: a first glass substrate 111 and a second glass plate Two glass substrates 112, wherein,

[0043] The first glass substrate 111 is located on the second glass substrate 112, and the first glass substrate 111 and the second glass substrate 112 are closely attached; wherein, the first part 1111 of the first glass substrate 111 is a curved surface to form the curved surface of the glass sheet.

[0044] The frame body may be the casing of the electronic device, or the middle frame body of the electronic device, for example, figure 1 The frame body 12 shown in may be only a middle frame body.

[0045] The manner in which the first part 1111 of the first glass substrate 111 is cl...

Embodiment 3

[0073] Embodiments of the present invention provide a method for making curved glass, such as Figure 10 As shown, the method includes:

[0074] Step 1001: processing the first glass substrate by grinding to form a first glass substrate satisfying the shape;

[0075] Step 1002: processing the second glass substrate by grinding to form a second glass substrate satisfying the shape;

[0076] Step 1003: welding the first glass substrate and the second glass substrate together by welding, so that the first glass substrate is located on the second glass substrate and the first glass substrate and the second glass substrate The two glass substrates are tightly bonded;

[0077] Step 1004: Grinding the first part of the first glass substrate to form a curvature, thereby forming a glass plate with at least a part of a curved surface.

[0078] Here, the shape satisfied by the first glass substrate may be ground according to actual needs, for example, the first glass substrate may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com