Abraded micro-particle online monitoring method adopting temperature control, adsorption and adjacent capacitor

A particle and capacitor technology, applied in the field of hydraulic systems, can solve the problem of unsatisfactory sensor sensitivity, achieve the effect of inhibiting the growth of bubbles, increasing the dielectric constant, and ensuring the reliability of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

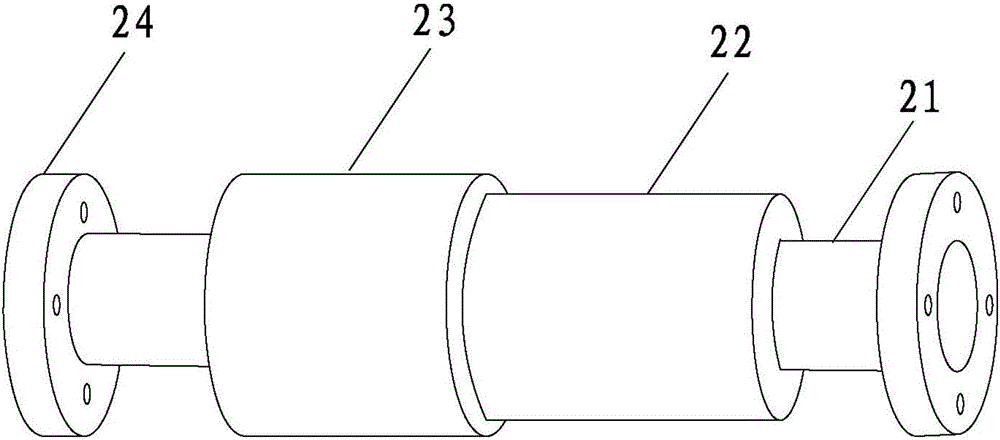

[0044] Please refer to the attached figure 1 to attach Figure 10 As shown, the present invention is an on-line monitoring method for wear particles using temperature control, adsorption and adjacent capacitors, which consists of a temperature control module 1, a magnetization module 2, a mechanical centrifugal module 3, an adsorption module 5, and an adjacent capacitor particle monitoring module 6. The degaussing module 7 and ECU10 are composed of several parts. Wherein, the temperature control module 1 , the magnetization module 2 , the mechanical centrifugal module 3 , the adsorption module 5 , the adjacent capacitive particle monitoring module 6 and the degaussing module 7 are connected in sequence.

[0045] One end of the temperature control module 1 is provided with an oil inlet 8 for inputting hydraulic oil into the device, which is composed of a heater, a cooler and a temperature sensor. The main purpose of the temperature control module 1 is to provide an optimum ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com