Cu-containing crack arrest steel and preparation method thereof

A technology of crack arrest and mass percentage, which is applied in the field of preparation of high-strength and high-toughness crack arrest steel for ships, and can solve the problems of low strength and no performance improvement of crack arrest steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

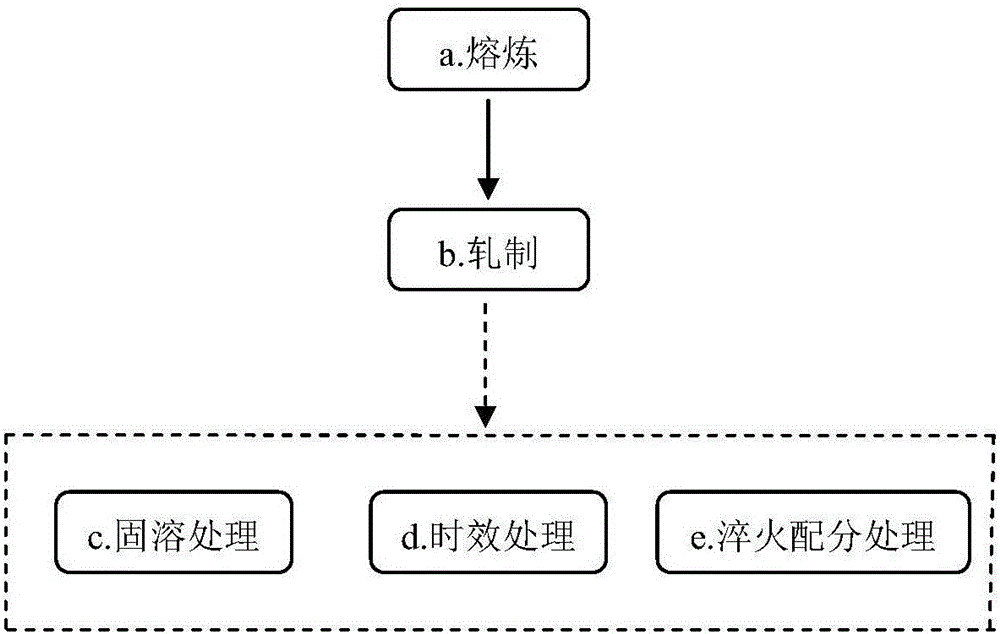

Method used

Image

Examples

Embodiment 1

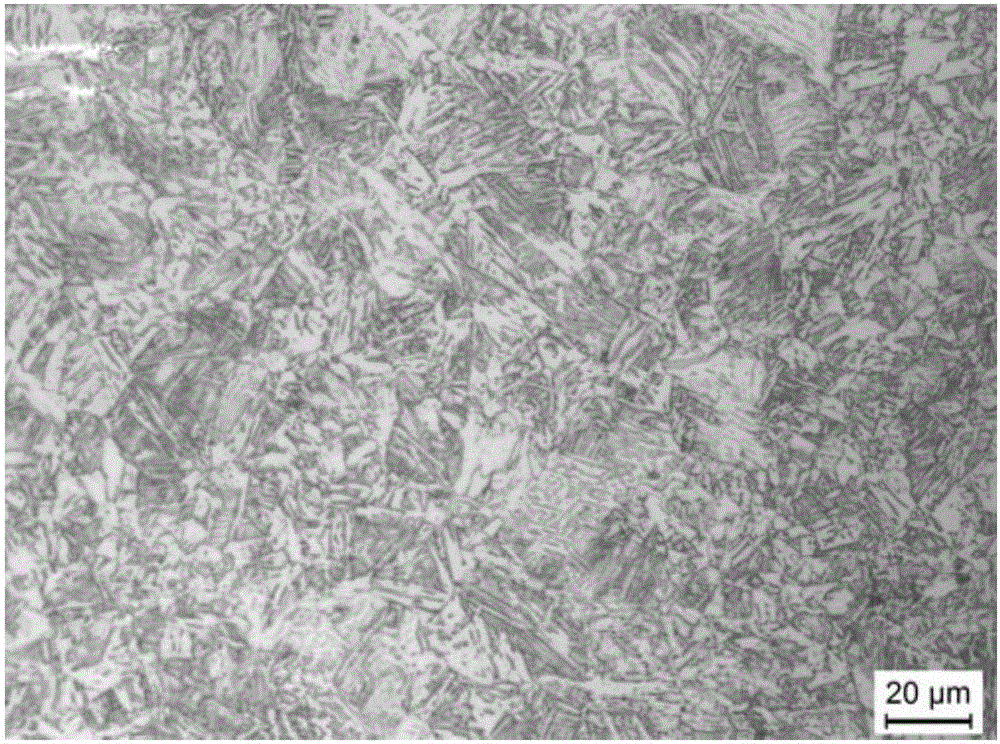

[0044] This example is a high-strength and high-toughness copper-containing crack arresting steel plate and its preparation method. The chemical composition is: C: 0.05%, Mn: 1.4%, Si: 0.14%, S: 0.003%, P: 0.004 %, Al: 0.034%, Cr: 0.18%, Ni: 0.75%, Cu: 0.38%, Nb: 0.024%, Ti: 0.012%, and the rest are Fe and unavoidable impurities. The rough rolling temperature is 1050°C, rolling 3 passes, with an average reduction of 18% each time, and a total reduction of 45%. The finish rolling start temperature is 900°C, the finish rolling temperature is 907°C, after rolling, it is watered and cooled to room temperature, and rolled for 5 passes, with an average reduction of 27% each time and a total reduction rate of 80%, to obtain a 12mm thick steel sheet. Crack plate. Does not undergo solidification, aging treatment and quenching partition treatment. Metallographic photos see figure 2 , the mechanical properties of the material see Figure 6 Table 1.

Embodiment 2

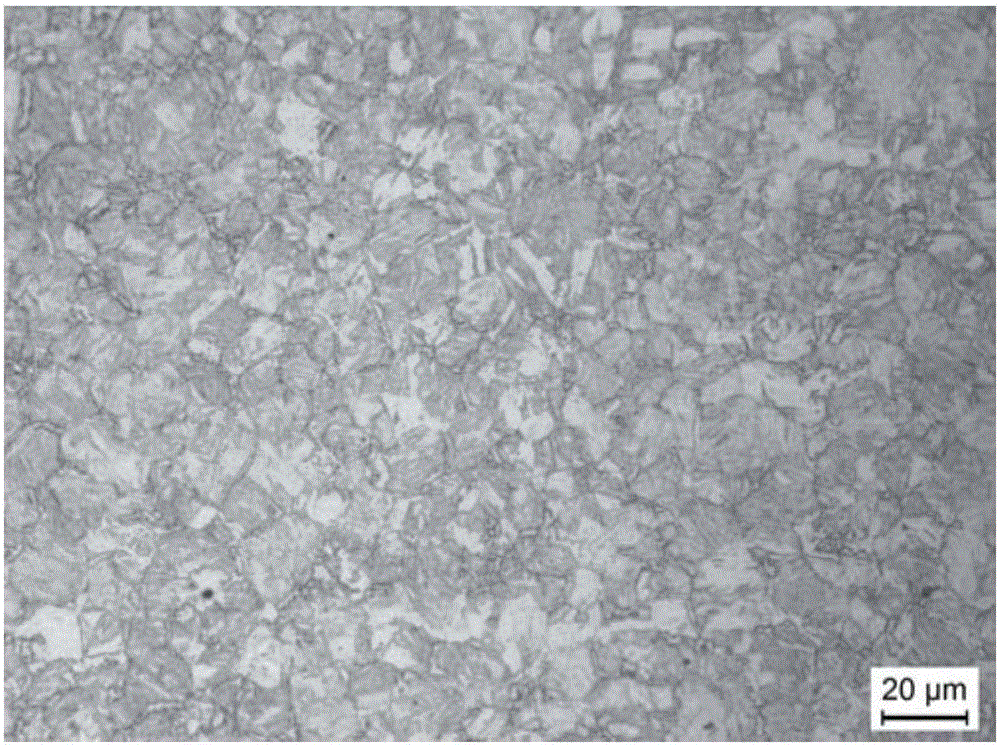

[0046] This example is a high-strength and high-toughness copper-containing crack arresting steel plate and its preparation method. The chemical composition is: C: 0.05%, Mn: 1.4%, Si: 0.14%, S: 0.003%, P: 0.004 %, Al: 0.034%, Cr: 0.18%, Ni: 0.75%, Cu: 0.38%, Nb: 0.024%, Ti: 0.012%, and the rest are Fe and unavoidable impurities. The rough rolling temperature is 1050°C, rolling 3 passes, with an average reduction of 18% each time, and a total reduction of 45%. The finish rolling start temperature is 900°C, the finish rolling temperature is 907°C, after rolling, it is watered and cooled to room temperature, and rolled for 5 passes, with an average reduction of 27% each time and a total reduction rate of 80%, to obtain a 12mm thick steel sheet. Crack plate. Solution treatment was carried out at 875°C, and the holding time was 1h. No aging treatment. Metallographic photos see image 3 , the mechanical properties of the material see Figure 6 Table 1.

Embodiment 3

[0048] This example is a high-strength and high-toughness copper-containing crack arresting steel plate and its preparation method. The chemical composition is: C: 0.05%, Mn: 1.4%, Si: 0.14%, S: 0.003%, P: 0.004 %, Al: 0.034%, Cr: 0.18%, Ni: 0.75%, Cu: 0.38%, Nb: 0.024%, Ti: 0.012%, and the rest are Fe and unavoidable impurities. The rough rolling temperature is 1050°C, rolling 3 passes, with an average reduction of 18% each time, and a total reduction of 45%. The finish rolling start temperature is 900°C, the finish rolling temperature is 907°C, after rolling, it is watered and cooled to room temperature, and rolled for 5 passes, with an average reduction of 27% each time and a total reduction rate of 80%, to obtain a 12mm thick steel sheet. Crack plate. Solution treatment was carried out at 925°C, and the holding time was 10h. No aging treatment. Metallographic photos see Figure 4 , the mechanical properties of the material see Figure 6 Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com