Carbon fiber forming process

A molding process, carbon fiber technology, applied in the direction of coating, can solve the problems of inability to make structural parts, low production efficiency, easy damage to strength, etc., to reduce shearing and heating time, long heating and shearing time, Avoid cost-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

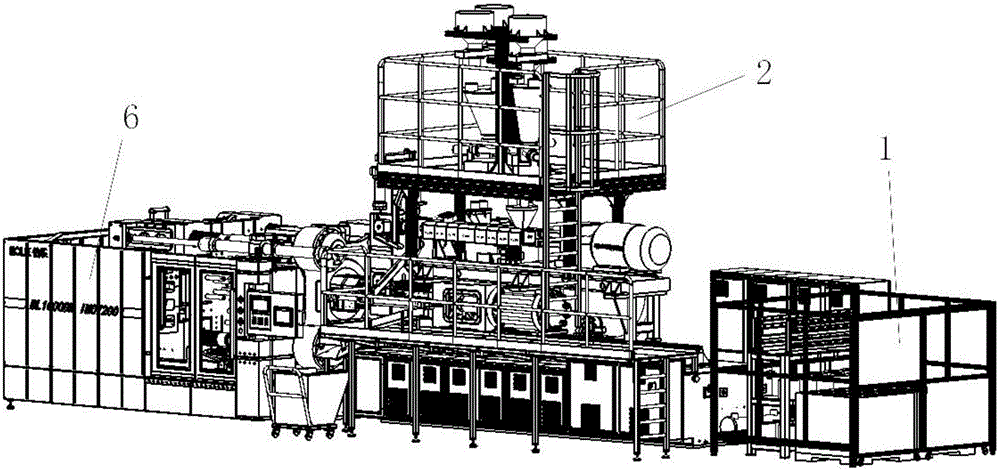

[0038] Like the carbon fiber forming equipment described above, the difference in this embodiment is that the fiber feeding structure 1 is used to store the continuous fibers, and transport the continuous fibers to the feeding control structure through a hose middle.

Embodiment 2

[0040] Like the carbon fiber molding equipment described above, the difference in this embodiment is that the plastic feeding structure 2 includes a feeding scale, the feeding scale is used to measure the formula material, and the plastic feeding structure 2 The structure is provided with at least one feeding scale, each of which is used to weigh a formula material, and the plastic feeding structure sends the formula material into the feeding control structure through the bottom material opening . The feeding scale is equipped with a corresponding replenishing bin and a feeding device for realizing the functions of feeding and feeding, which facilitates continuous production, and the shape of the formula material includes granular.

Embodiment 3

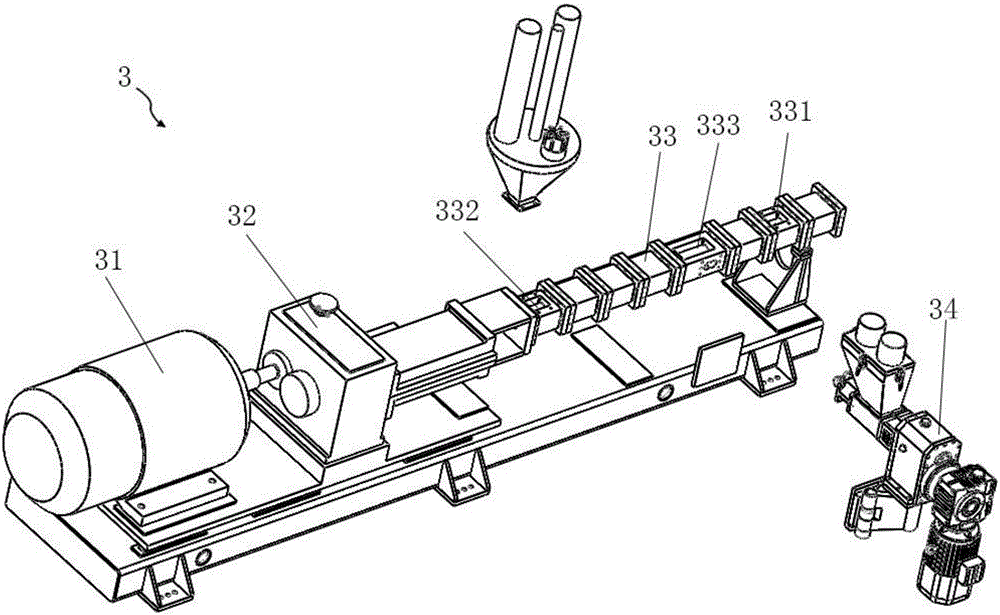

[0042] As the above-mentioned carbon fiber forming equipment, the present embodiment is different from it in that, as figure 2 As shown, the compounding structure 3 is used to shear and melt the material to be processed; the compounding structure 3 includes: a motor 31, a reducer 32, a screw assembly, and a screw barrel 33;

[0043]The motor 31 is used to provide power for the compounding process, the output shaft of the motor 31 is connected to the input end of the reducer 32, and the output end of the reducer 32 is connected to the fixed end of the screw assembly, The reducer 32 is used to drive the screw assembly to rotate around the axis; the screw assembly is composed of at least two screws arranged side by side, and at least one helix is provided on the screw, when the material to be processed When moving along the advancing direction of the helix, various forms of helixes are provided, and the combination of various forms of helixes is more conducive to the shearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com