Diversified use fixture of exhaust pipe assembly

A technology of exhaust pipe and assembly, which is applied in the field of diversified utilization of inspection tools for exhaust pipe assembly, which can solve the problem of increasing the production cost of exhaust pipe assembly, the workload of early stage debugging of exhaust pipe assembly, and the curvature of exhaust pipe fittings Problems such as inconsistent twisting angles and low structural stability of the exhaust pipe assembly have achieved good market promotion prospects, guaranteed product quality, and avoided repeated calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

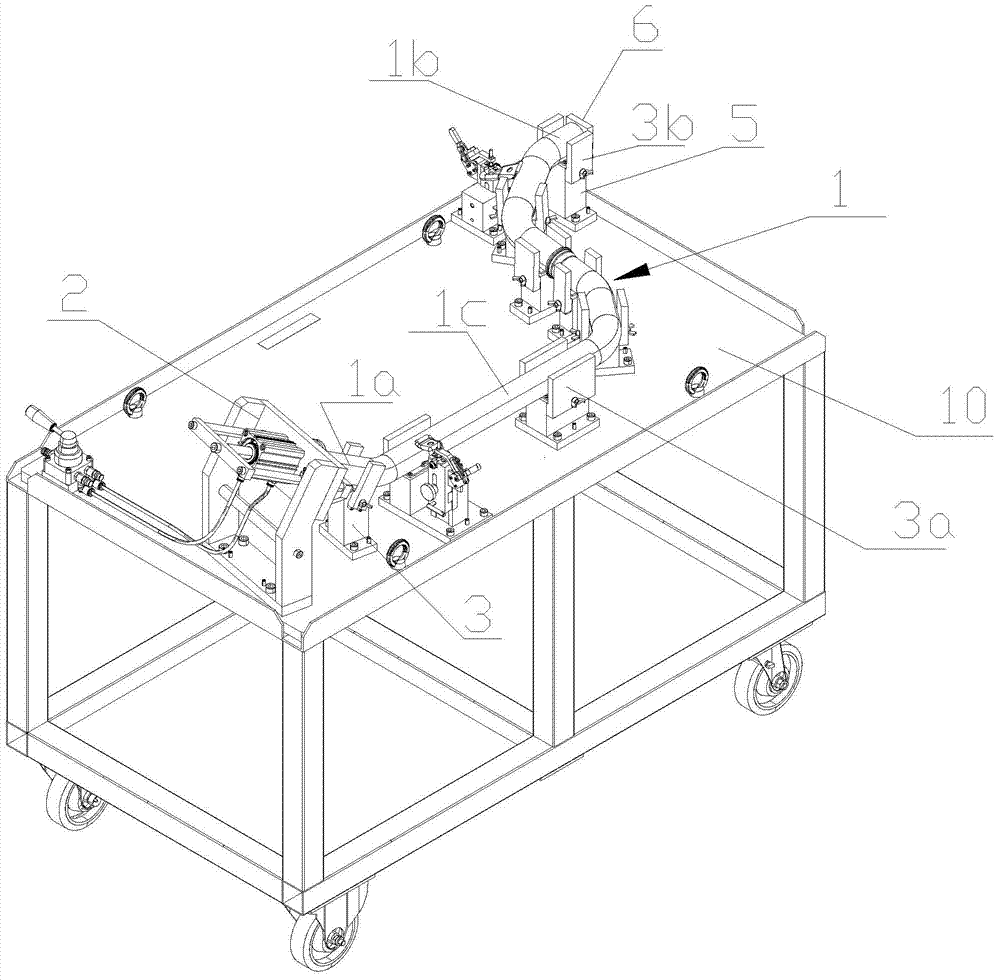

[0018] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

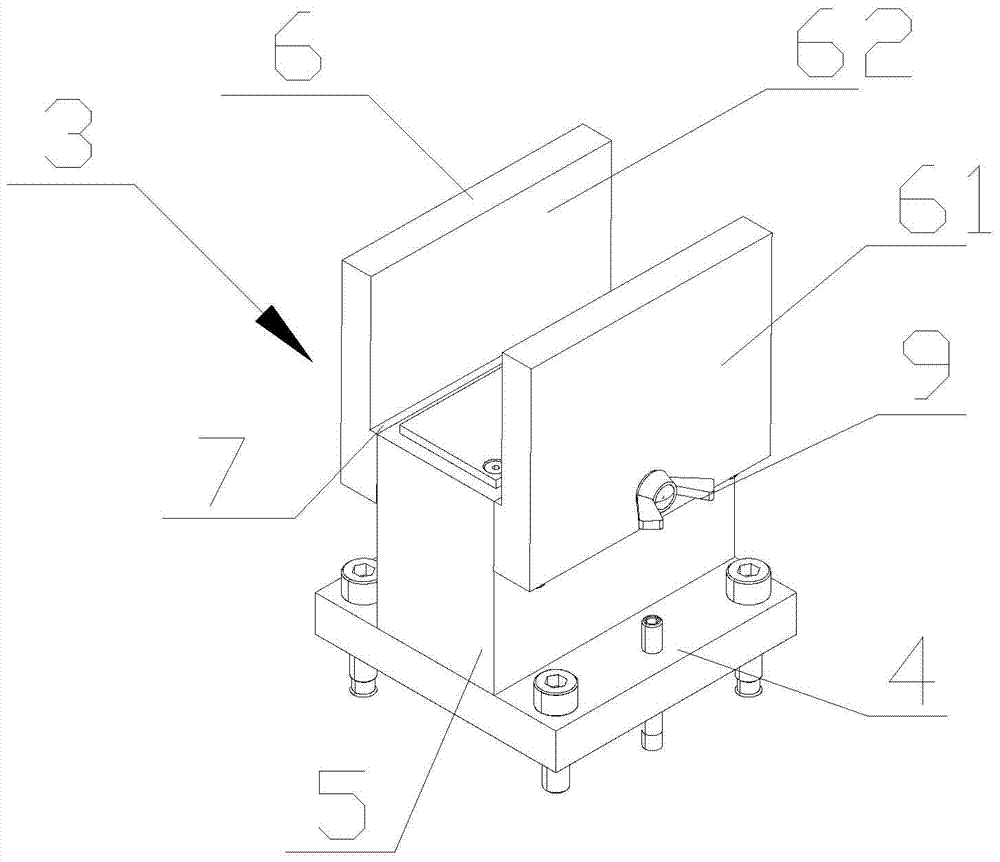

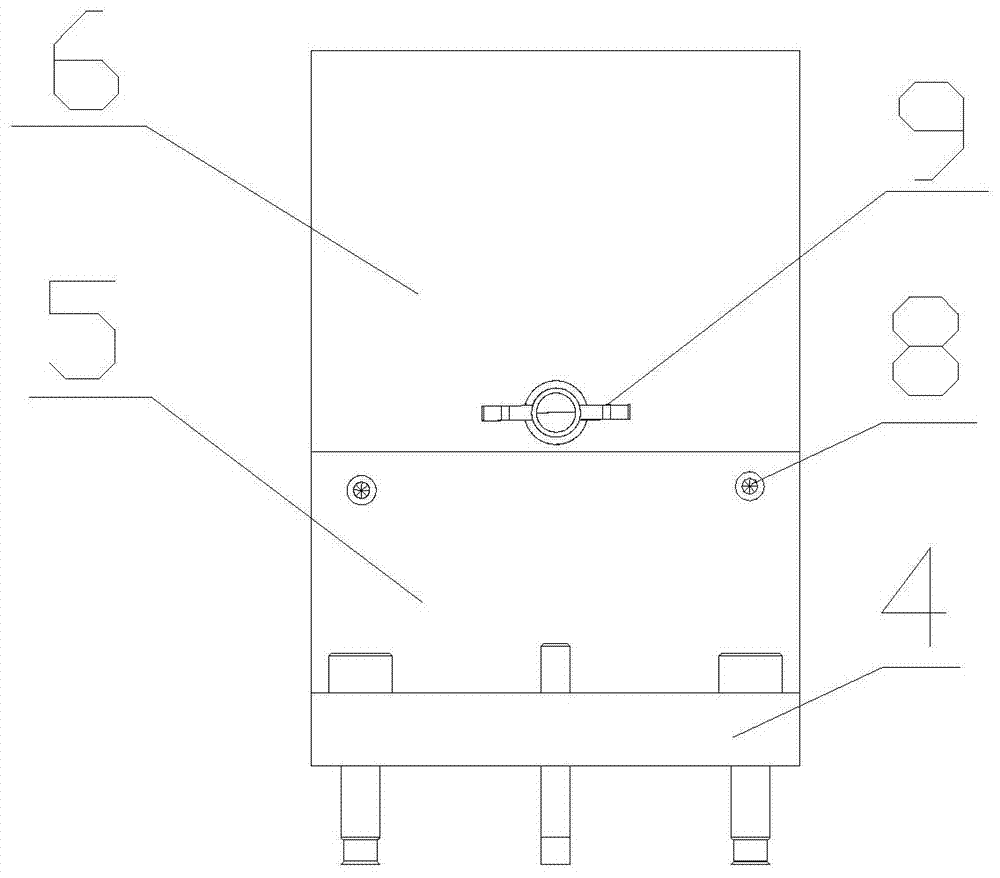

[0019] Referring to the accompanying drawings, it can be seen that the multi-use inspection tool for the exhaust pipe assembly is characterized in that it includes a base 4 installed on the workbench 10, a support table 5 installed on the base 4, and a number of movable limit blocks 6, The first side of the movable limiting block 6 is a reference plane 61, the second side of the movable limiting block 6 is a detection surface 62 with a notch groove 7, and the two sides of the upper part of the support table 5 are in contact with the reference surface 61 or the detection surface. Surface 62 is connected.

[0020] The rear end of the support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com