Injection mould capable of preventing sliding block from failure

A technology of injection molds and sliders, applied in the field of injection molds, can solve the problems of high core pulling force and affecting the quality of injection molding, and achieve the effects of easy operation, easy promotion and use, and avoiding cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

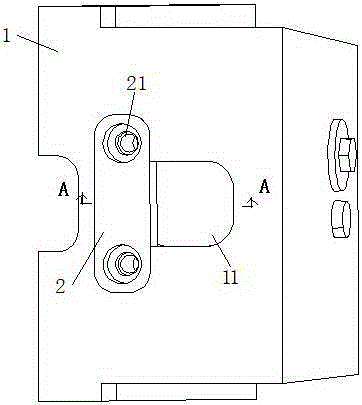

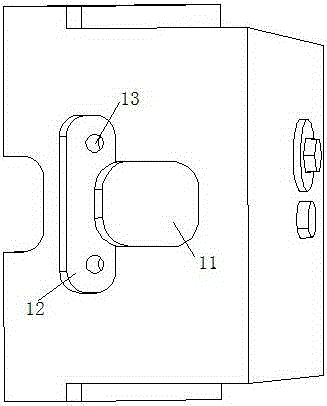

[0029] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , in this example one An injection mold for preventing slider failure, including a dynamic mold, a static mold, and a slider 1, which also includes a barb 3 and a pressure plate 2, the pressure plate 2 is fixedly connected to the slider 1, and the slider 1 is fixedly connected to the static mold. Hook 3 is fixedly connected with moving mold.

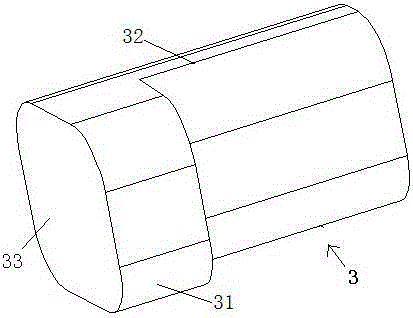

[0030] The barb 3 is an L-shaped structure, which includes a hook section 31 and a fixed section 32. The fixed section 32 is fixedly connected with the movable mold. The hook section 31 is a cuboid structure, and its lower end surface 33 is a square. Transition through arcs.

[0031] The center of the upper end surface of the slider 1 is provided with a square pit 11 and a pressure plate groove 12, the pressure plate groove 12 is located on one side of the square pit 11, the pressure plate groove 12 communicates with the square pit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com