Stamping die for metal tee parts

A technology for stamping dies and parts, applied in the field of stamping dies for metal tee parts, can solve problems such as affecting the surface quality of finished parts, unsuitable for die-casting production, low strength, etc. The effect of improving utilization rate and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

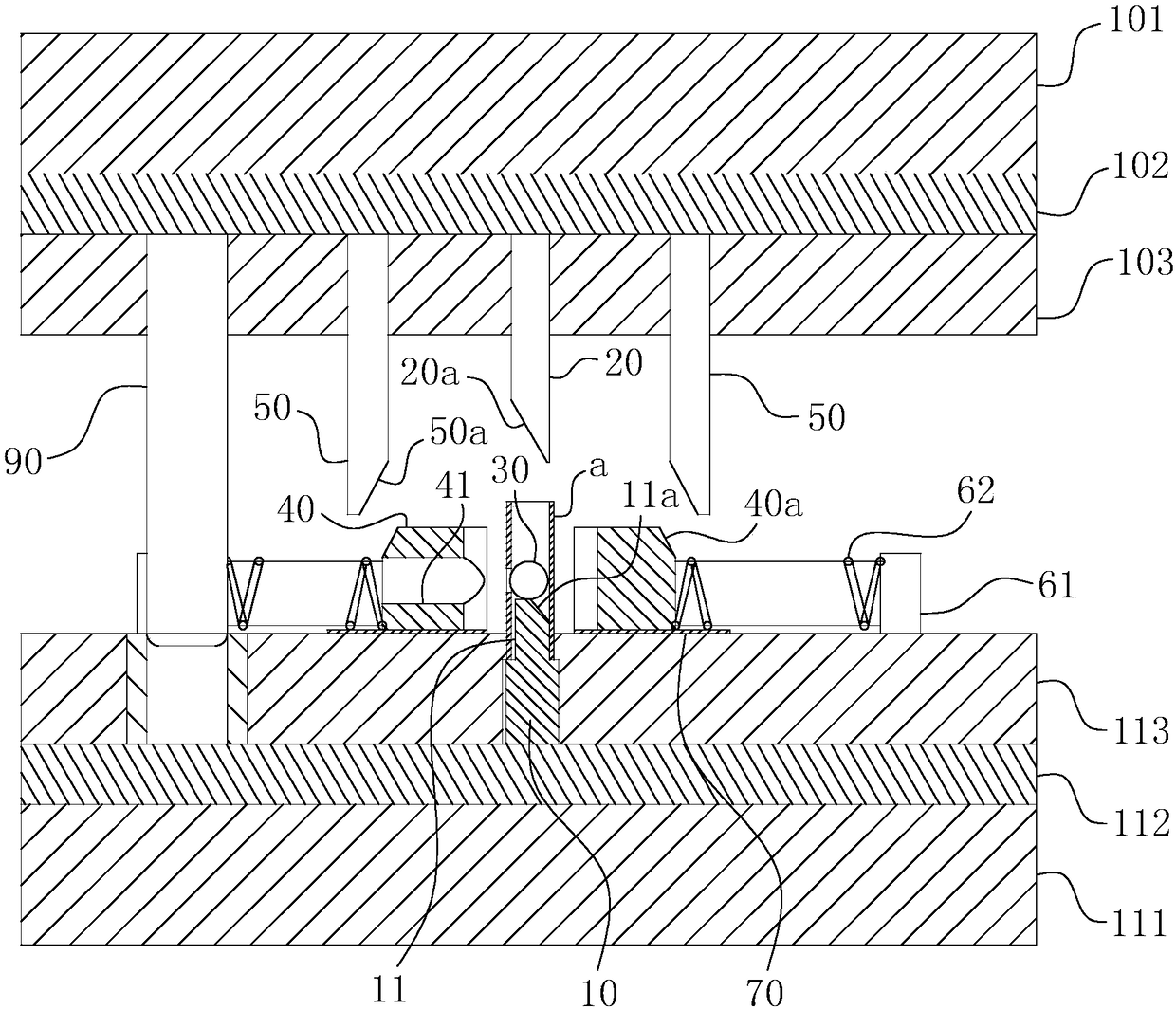

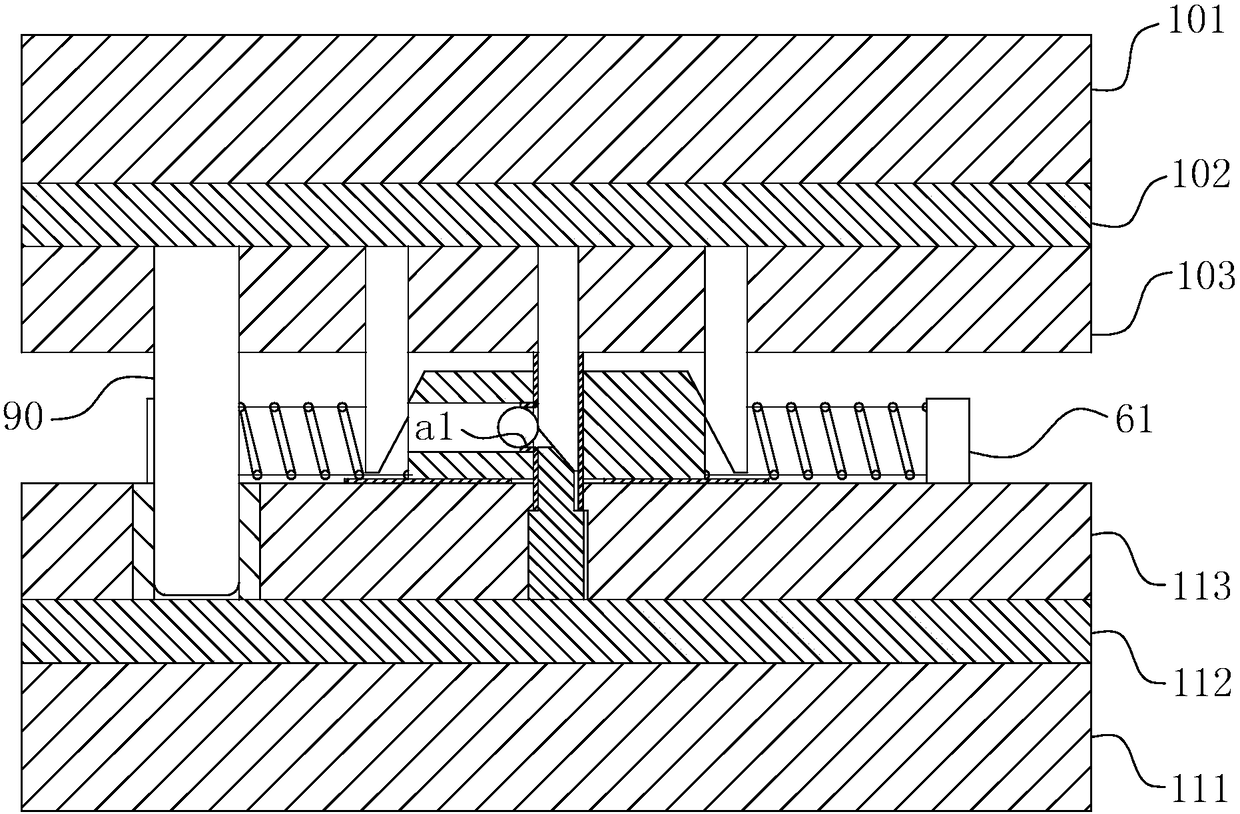

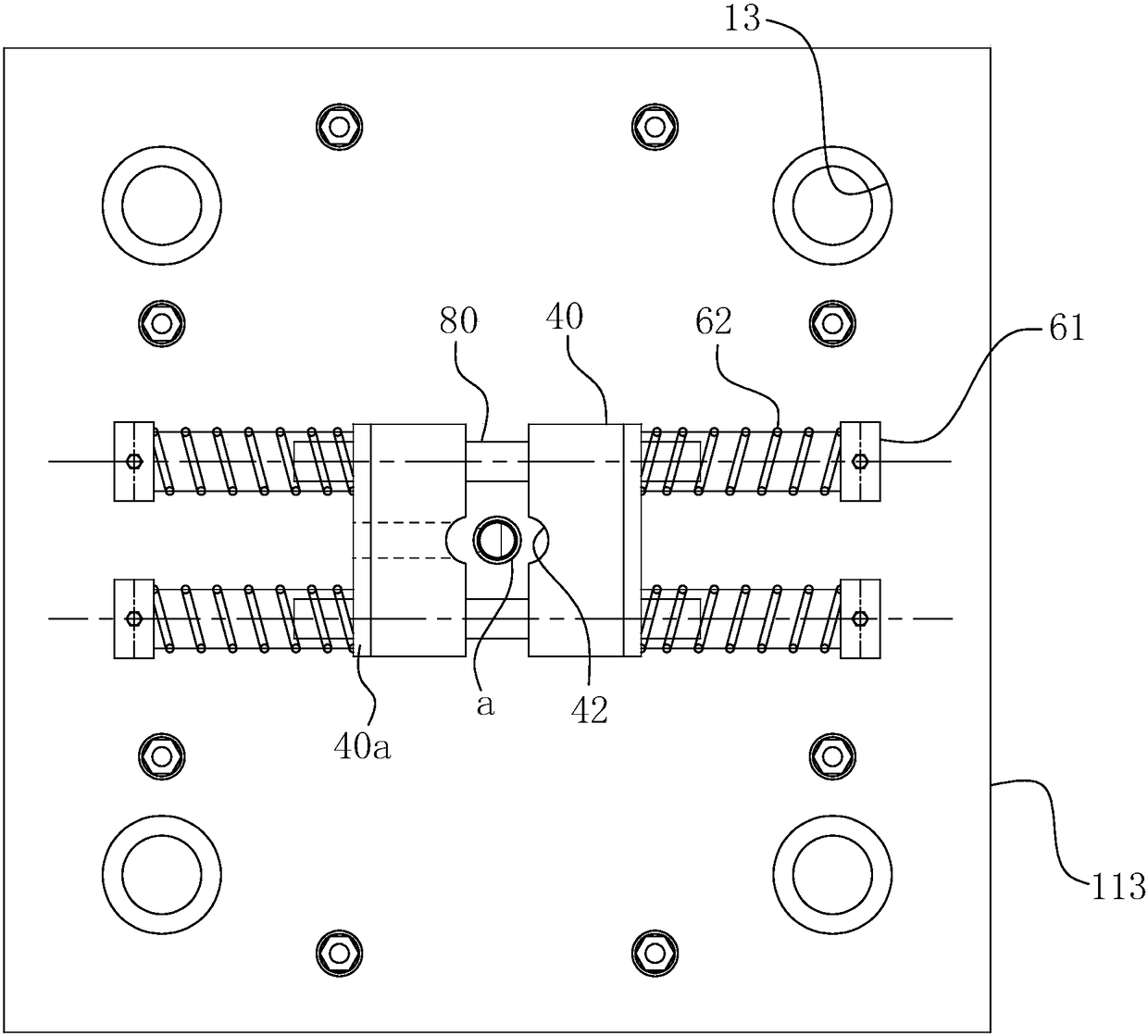

[0041] For ease of understanding, combined here Figure 1-4 The specific embodiment figure further describes structure of the present invention and working process:

[0042] The specific structure of the present invention is as Figure 1-3 As shown, its main body frame is made of upper die, lower die and guide post 90; The upper mold includes an upper mold plate 101, an upper mold backing plate 102 and a punch fixing plate 103 stacked from top to bottom, and a lower mold includes a die fixing plate 113, a lower mold backing plate 112 and a lower mold fixing plate 113 stacked from top to bottom. template111.

[0043] As the basic installation body of the working parts of the mold, such as Figure 1-2 and Figure 4 As shown, the die fixing plate 113 and the punch fixing plate 103 are provided with some holes such as fixing holes. The die fixing plate 113 is inserted and fixed in the plate body: a guide sleeve hole 13 for arranging a guide sleeve to form a guide post guide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com