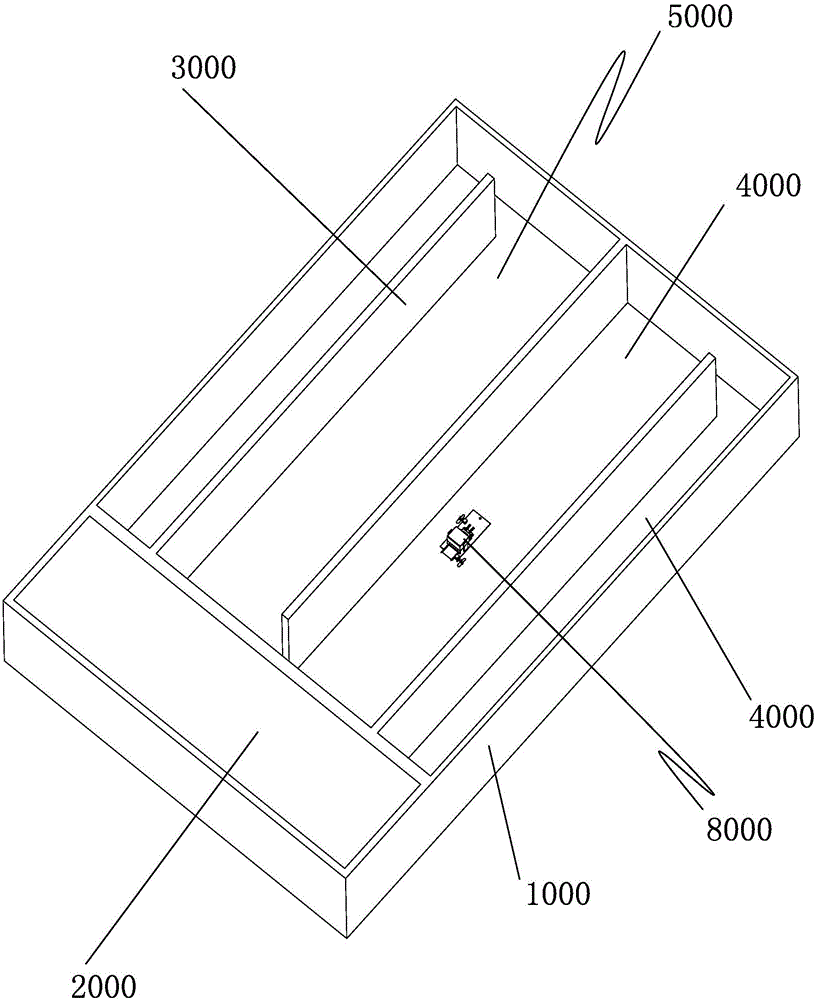

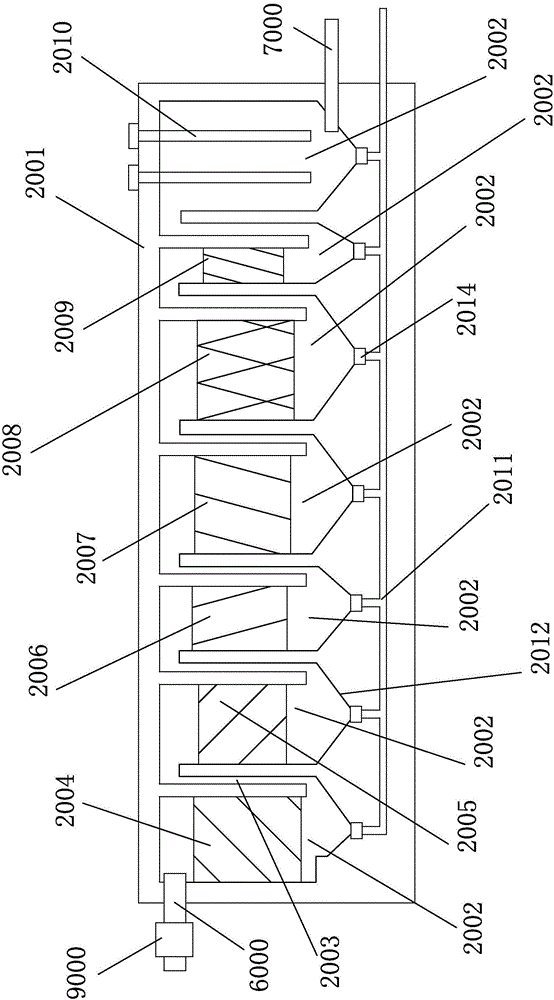

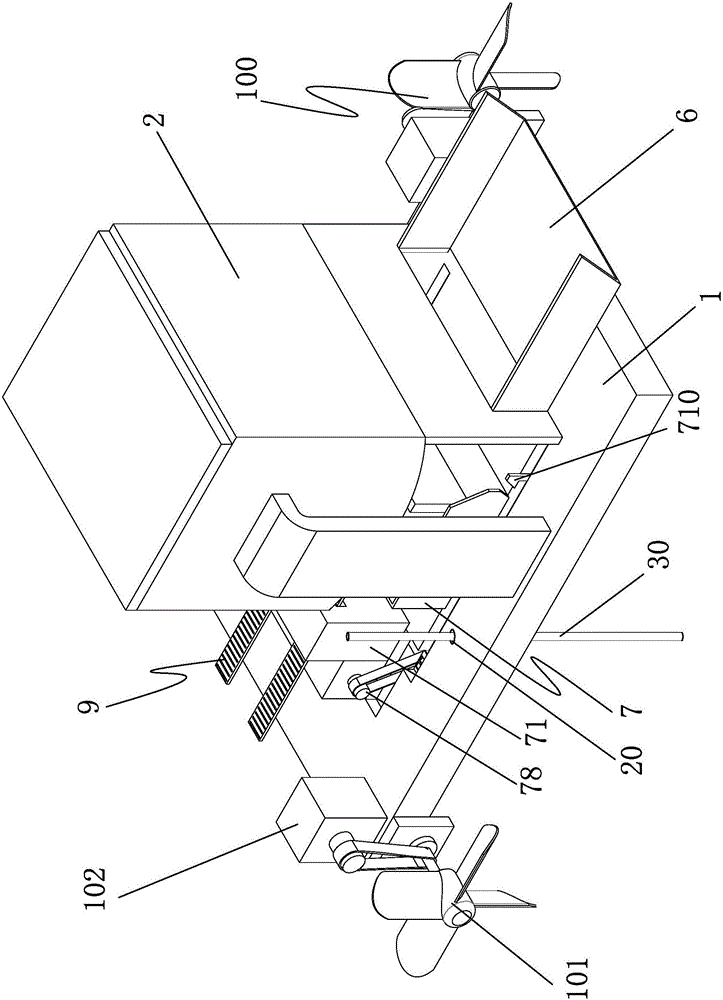

Cycling freshwater outdoor pond aquaculture facility

A pond and facility technology, applied in fish farming, coating, animal husbandry, etc., can solve the problems of lack of suitable growth environment for cultured organisms, unbalanced water quality in ponds, low production efficiency, etc., and achieves good rust prevention effect. , The effect of simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In the present invention, the degree of automation is high, only need to manually pour the material into the discharge box, and the automatic feeding can be realized by setting the feeding time interval and feeding amount on the controller, which saves time and effort, is not affected by the weather, and can control the amount of feeding. Precise control avoids the waste of bait. Example 1 - Anti-rust coating

[0065] Antirust coating of the present invention comprises following component by weight percentage:

[0066]

[0067] Preparation method: Mix and stir graphene, strontium chromate, trilead tetraoxide, ammonium metaborate, and zinc phosphate evenly, grind in a conical grinder until the fineness is <60 μm, then add silicone-modified acrylate emulsion, ortho Dibutyl phthalate, propylene glycol methyl ether and other components are uniformly dispersed.

[0068] Example 2 - Anti-rust coating

[0069] Antirust coating of the present invention comprises following...

Embodiment 4

[0077] Example 4 - Corrosion Resistant Coating

[0078] Corrosion-resistant coatings include the following components by weight percentage:

[0079]

[0080]

[0081] Preparation method: Mix fluorinated acrylate and coal tar pitch evenly, stir and heat to 45°C, stir for 10 minutes, add aluminum tripolyphosphate and zinc citrate, heat to 120°C, stir for 3 hours, cool to 50°C, add other The components were stirred and kept for 1 hour, ultrasonically dispersed for 10 minutes, and ground to a fineness of <60 μm in a conical grinder.

Embodiment 5

[0082] Example 5 - Corrosion Resistant Coating

[0083] Corrosion-resistant coatings include the following components by weight percentage:

[0084]

[0085] Preparation method: Mix fluorinated acrylate and coal tar pitch evenly, stir and heat to 60°C, stir for 60 minutes, add aluminum tripolyphosphate and zinc citrate, heat to 145°C, stir for 5 hours, cool to 60°C, add other The components were stirred and kept for 2 hours, ultrasonically dispersed for 25 minutes, and ground to a fineness of <60 μm in a conical grinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com