Compositions for high speed printing of conductive materials for electronic circuitry type applications, and methods relating

A high-speed printing, conductive material technology, applied in applications, household appliances, inks, etc., can solve the problems of limited scalability, low deposition speed, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

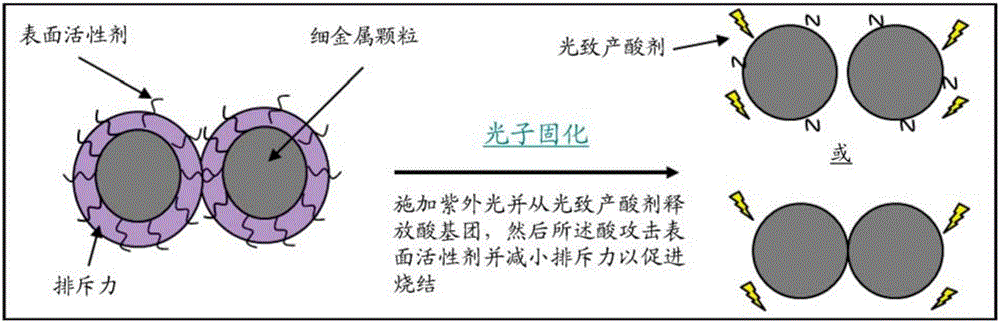

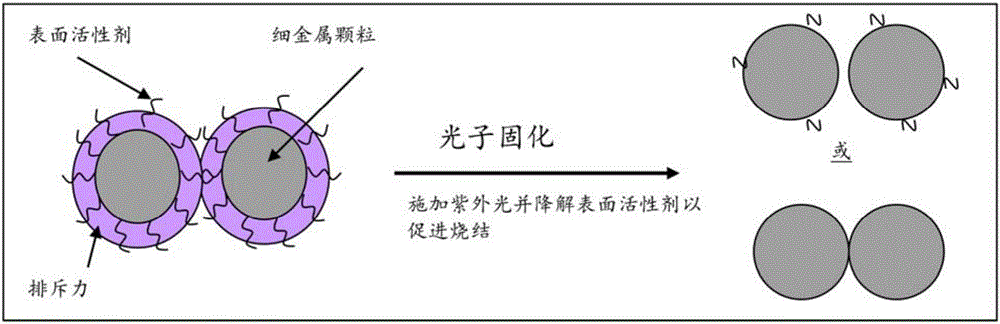

[0070] The present disclosure also relates to production methods and substrates having conductive metallizations produced by said production methods. The preparation method comprises the following steps:

[0071] (1) Provide the substrate,

[0072] (2) applying the conductive composition of the present invention to a substrate, and

[0073] (3) Subjecting the conductive composition applied in step (2) to photonic sintering to form a conductive metallization.

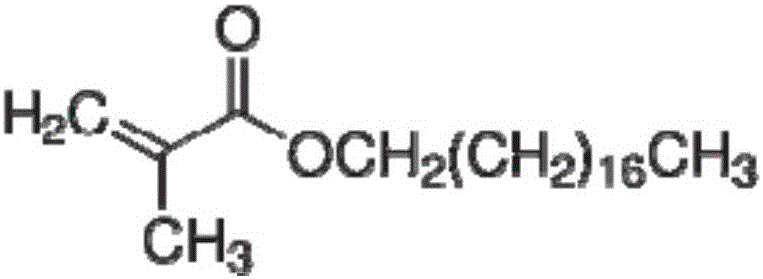

[0074] For embodiments in which the decomposable stabilizer comprises groups acidolyzed by catalytically active methods, photonic sintering can be performed with the aid of photoacid generators as shown in Table 1 below:

[0075]

[0076] Table 1

[0077] The "surfactants" indicated in Table 1 are intended to mean the thermally decomposable stabilizers of the present disclosure, or alternatively may denote co-surfactants in addition to the thermally decomposable stabilizers, wherein in addition to or independently ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com