A kind of decorative base paper strengthening agent and preparation method thereof

A technology for decorating base paper and reinforcing agent, applied in the direction of reinforcing agent addition, papermaking, paper, etc., can solve problems such as paper breakage and insufficient strength, and achieve the effect of reducing the amount of use, reducing the use of water, and reducing the amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

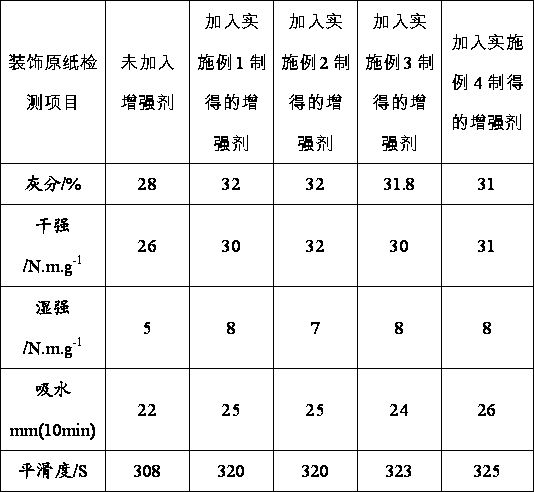

Examples

Embodiment 1

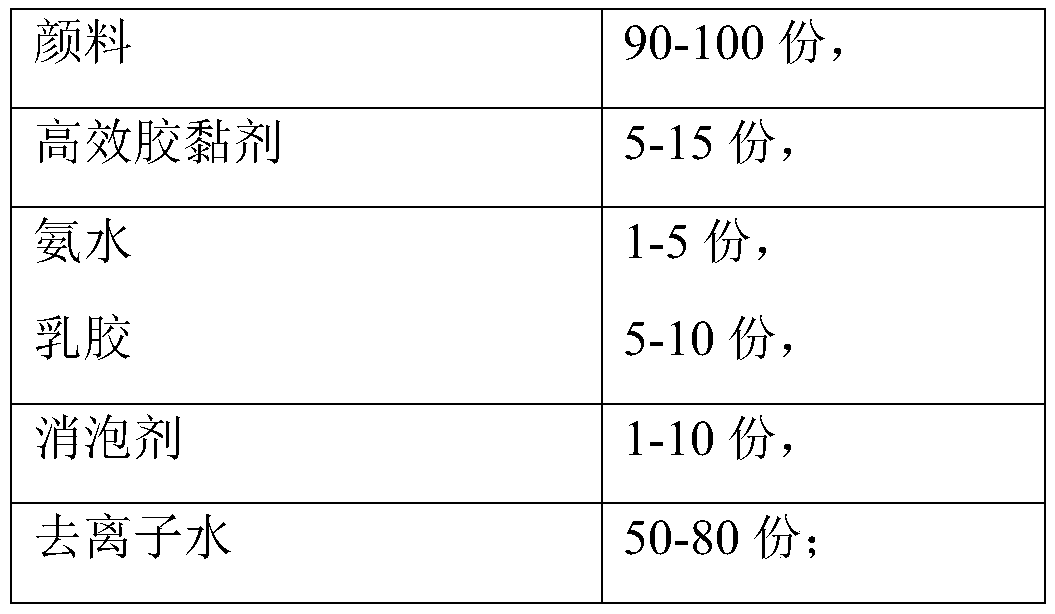

[0015] Embodiment 1, this embodiment provides a decorative base paper reinforcing agent and a preparation method thereof. First, prepare a high-efficiency adhesive as follows: Weigh 2g of sodium polyacrylate, 20g of polyvinyl alcohol, and 5g of styrene-acrylic emulsion, mix them, and react at 120°C for 3 hours; after the reaction, cool down to 80°C, and then add 5g of methacrylic acid, React for 6 hours, then cool to room temperature to obtain a milky white high-efficiency adhesive.

[0016] The substances in the reinforcing agent are formulated as follows by weight fraction (excluding water and pH regulator): 90 parts of 95-grade GCC pigment, 1 part of defoamer, 2 parts of latex, 1 part of ammonia water, and 5 parts of high-efficiency adhesive. The preparation steps are as follows: add the pigment into the batching tank, which contains enough water to disperse the pigment, disperse at a high speed for 20 minutes, and the speed of the high-speed dispersion is 800 rpm to obtain...

Embodiment 2

[0017] Embodiment 2, this embodiment provides a decorative base paper reinforcing agent and a preparation method thereof. First, prepare a high-efficiency adhesive as follows: Weigh 2g of sodium polyacrylate, 38g of polyvinyl alcohol, and 10g of styrene-acrylic emulsion in turn, mix them, and react at 120°C for 3 hours; after the reaction, cool down to 70°C, then add 5g of methacrylic acid, and react 5 hours, and then cooled to room temperature to obtain a milky white high-efficiency adhesive.

[0018] Each substance in the reinforcing agent is prepared as follows according to the weight fraction: 90 parts of 95-grade GCC pigment, 1 part of defoamer, 3 parts of latex, 1 part of ammonia water, and 10 parts of high-efficiency adhesive. The preparation steps are: add the pigment into the batching tank, disperse at a high speed for 25 minutes, and the speed of the high-speed dispersion is 1000 rpm to obtain the mixture a; add the high-efficiency adhesive and latex to the water, re...

Embodiment 3

[0019] Embodiment 3, this embodiment provides a decorative base paper reinforcing agent and a preparation method thereof. First, prepare a high-efficiency adhesive as follows: Weigh 5g of sodium polyacrylate, 38g of polyvinyl alcohol, and 10g of styrene-acrylic emulsion, mix them, and react at 120°C for 2 hours; after the reaction, cool down to 75°C, then add 5g of methacrylic acid, and react 5.5 hours, and then cooled to room temperature to obtain a milky white high-efficiency adhesive.

[0020] The substances in the reinforcing agent are prepared as follows according to the weight fraction: 100 parts of china clay, 1 part of defoamer, 2 parts of latex, 1 part of ammonia water, and 5 parts of high-efficiency adhesive. The preparation steps are: add the pigment into the batching tank, disperse at a high speed for 20 minutes, and the speed of the high-speed dispersion is 1000 rpm to obtain the mixture a; add the high-efficiency adhesive and latex to the water, react at 120°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com