A kind of corrosion-resistant steel bar and its production method

A production method and steel bar technology, applied in the field of metallurgical technology, can solve the problems of no specific requirements for the cleanliness of molten steel, no attention to cleanliness, and limited room for improvement, so as to improve corrosion resistance, reduce inclusions, and reduce inclusions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The concrete production method of embodiment smelting and continuous casting is:

[0035] Electric furnace smelting:

[0036]High-quality scrap steel is used, and the slagging operation is carried out after the scrap steel is melted. According to the initial composition of the molten steel, carburizers, ferrosilicon manganese, and ferrosilicon are first added for deoxidation and alloying, and then ferrochrome and ferrotitanium are added for alloying, and then smelted Tapping is carried out after the components meet the requirements, and the tapping temperature is controlled at 1650-1670°C.

[0037] Continuous casting:

[0038] After the steel is tapped to the ladle, the ladle is hoisted to the tundish, and the superheat of the molten steel is controlled at ≤30°C.

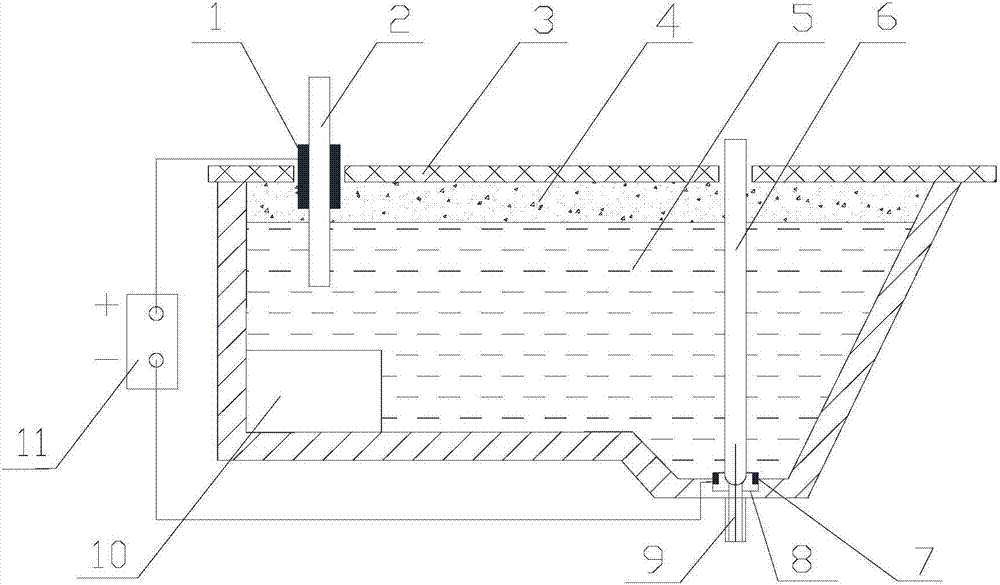

[0039] The tundish 3 is deoxidized using an applied electric field slag deoxidizer. When pouring, lower the shroud 2 into the tundish 3, at this time the anode 1 is in the slag 4, and the molten steel 5 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com