Green and environment-friendly diesel oil for vehicles and preparation method thereof

A green and environmentally friendly technology for vehicles, applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., can solve the problems of excessive vehicle exhaust emissions, increased pollutant content, increased dust particles, etc., to achieve less pollutant emissions, toxic The effect of reducing harmful components, reducing carbon deposition and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

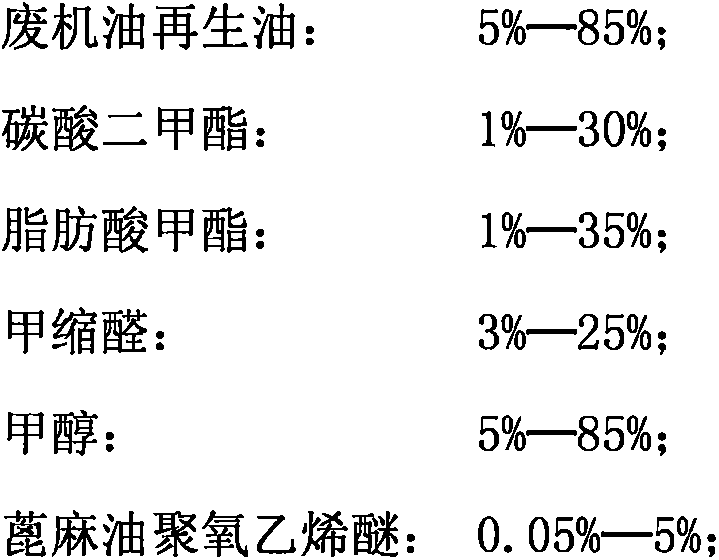

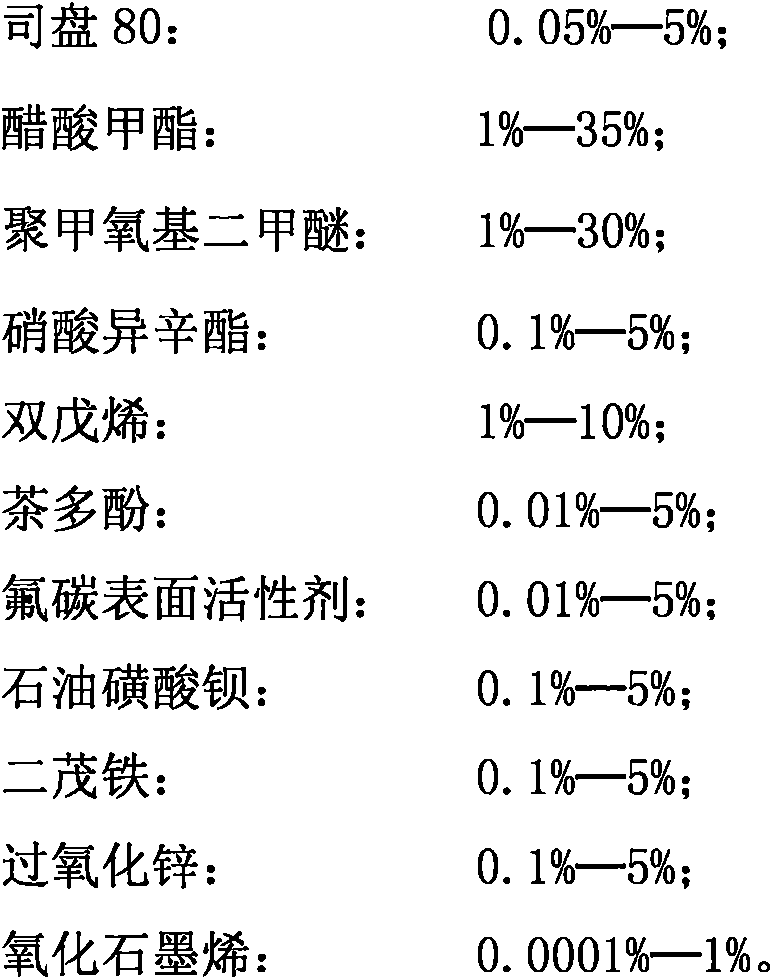

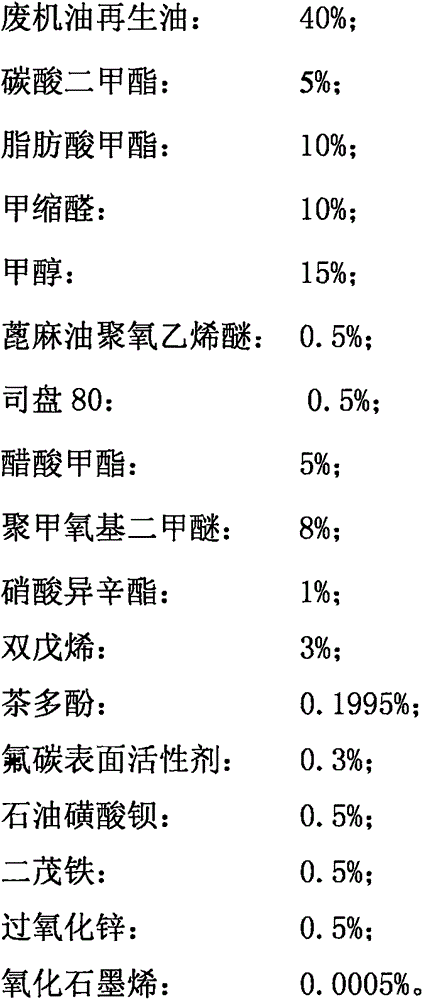

[0028] A kind of green environment-friendly diesel oil suitable for vehicles, the components and raw materials are selected according to the parts by weight for subsequent use:

[0029] Regenerated waste engine oil: 40 kg; Dimethyl carbonate: 5 kg; Fatty acid methyl ester: 10 kg; Methylal: 10 kg; Methanol: 15 kg; Castor oil polyoxyethylene ether: 0.5 kg; Span 80: 0.5 kg; methyl acetate: 5 kg; polyoxymethylene dimethyl ether: 8 kg; isooctyl nitrate: 1 kg; dipentene: 3 kg; tea polyphenols: 0.1995 kg; fluorocarbon surfactant: 0.3 kg ; Barium petroleum sulfonate: 0.5 kg; Ferrocene: 0.5 kg; Zinc peroxide: 0.5 kg; Graphene oxide: 0.0005 kg.

[0030] A kind of green environment-friendly diesel oil that is applicable to vehicle, the method step of production preparation is:

[0031]First preheat the regenerated waste engine oil, the heating temperature is controlled between 50°C and 90°C, and pump it into the stirring tank at normal temperature and pressure; turn on the agitator, add...

Embodiment 2

[0033] A kind of green environment-friendly diesel oil suitable for vehicles, the components and raw materials are selected according to the parts by weight for subsequent use:

[0034] Regenerated waste engine oil: 35 kg; Dimethyl carbonate: 5 kg; Fatty acid methyl ester: 15 kg; Methylal: 10 kg; Methanol: 15 kg; Castor oil polyoxyethylene ether: 0.5 kg; Span 80: 0.5 kg; methyl acetate: 8 kg; polyoxymethylene dimethyl ether: 5 kg; isooctyl nitrate: 2 kg; dipentene: 2 kg; tea polyphenols: 0.199 kg; fluorocarbon surfactant: 0.5 kg ; Barium petroleum sulfonate: 0.3 kg; Ferrocene: 0.5 kg; Zinc peroxide: 0.5 kg; Graphene oxide: 0.001 kg.

[0035] A kind of green environment-friendly diesel oil that is applicable to vehicle, the method step of production preparation is:

[0036] First preheat the regenerated waste engine oil, the heating temperature is controlled between 50°C and 90°C, and pump it into the stirring tank at normal temperature and pressure; turn on the agitator, add ...

Embodiment 3

[0038] A kind of green environment-friendly diesel oil suitable for vehicles, the components and raw materials are selected according to the parts by weight for subsequent use:

[0039] Regenerated waste engine oil: 55 kg; Dimethyl carbonate: 5 kg; Fatty acid methyl ester: 5 kg; Methylal: 5 kg; Methanol: 10 kg; Castor oil polyoxyethylene ether: 0.5 kg: Span 80: 0.5 kg; methyl acetate: 3 kg; polymethoxy dimethyl ether: 10 kg; isooctyl nitrate: 1 kg; dipentene: 3 kg; tea polyphenols: 0.199 kg; fluorocarbon surfactant: 0.5 kg ; Barium petroleum sulfonate: 0.3 kg; Ferrocene: 0.5 kg; Zinc peroxide: 0.5 kg; Graphene oxide: 0.001 kg.

[0040] A kind of green environment-friendly diesel oil that is applicable to vehicle, the method step of production preparation is:

[0041] First preheat the regenerated waste engine oil, the heating temperature is controlled between 50°C and 90°C, and pump it into the stirring tank at normal temperature and pressure; turn on the agitator, add the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com