Reinforcing flexibilizer used for 3D printing of ABS, ABS composite material, production method of ABS composite material

A technology of strengthening and toughening and 3D printing, which is applied in the direction of additive processing, etc., can solve the problems of high shrinkage, insufficient toughness and strength of ABS, warping and other problems, achieve small shrinkage, improve toughness and strength, and reduce irritating odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

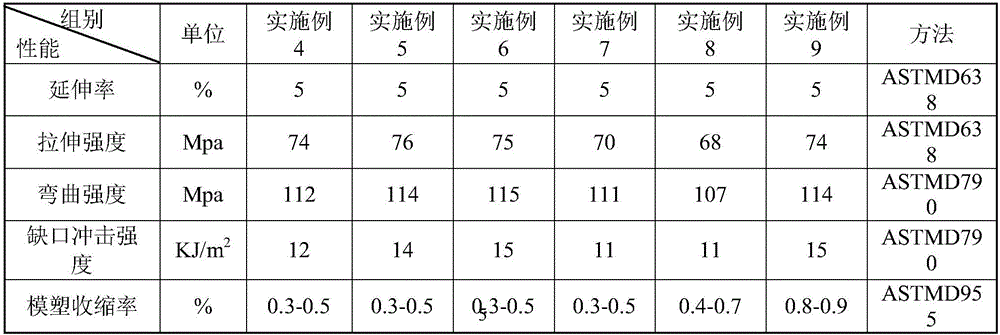

Examples

Embodiment 1

[0024] A reinforcing and toughening agent for 3D printing ABS, which is made by fully mixing the following raw materials: 150g of carbon black with a particle size of 30nm; 40g of glass fiber with a monofilament diameter of 2μm and an aspect ratio of 6; 70 g of 10 μm SBS resin powder.

Embodiment 2

[0026] A reinforcing and toughening agent for 3D printing ABS, which is made by fully mixing the following raw materials: 270g of carbon nanotubes with a particle size of 65nm; 65g of glass fibers with a monofilament diameter of 5.6μm and an aspect ratio of 8.2; 100 g of SBS resin powder with a particle diameter of 15 μm.

Embodiment 3

[0028] A reinforcing and toughening agent for 3D printing ABS, which is made by fully mixing the following raw materials: 270g of graphene with a particle size of 80nm; 65g of glass fibers with a monofilament diameter of 8μm and an aspect ratio of 10; 100 g of 20 μm SBS resin powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com