Flange heating pipe

A flange heating and electric heating tube technology, applied in the field of flange heating tubes, can solve the problems of large heating area of electric heating tubes, uneven heating of water body, short service life of electric heating tubes, etc., to avoid heat concentration, simple structure and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

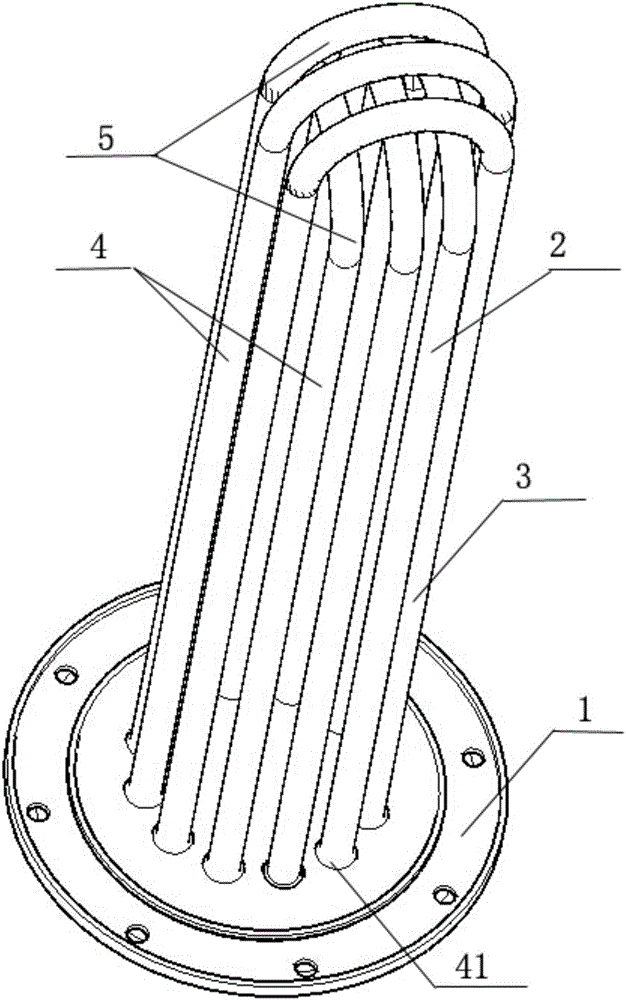

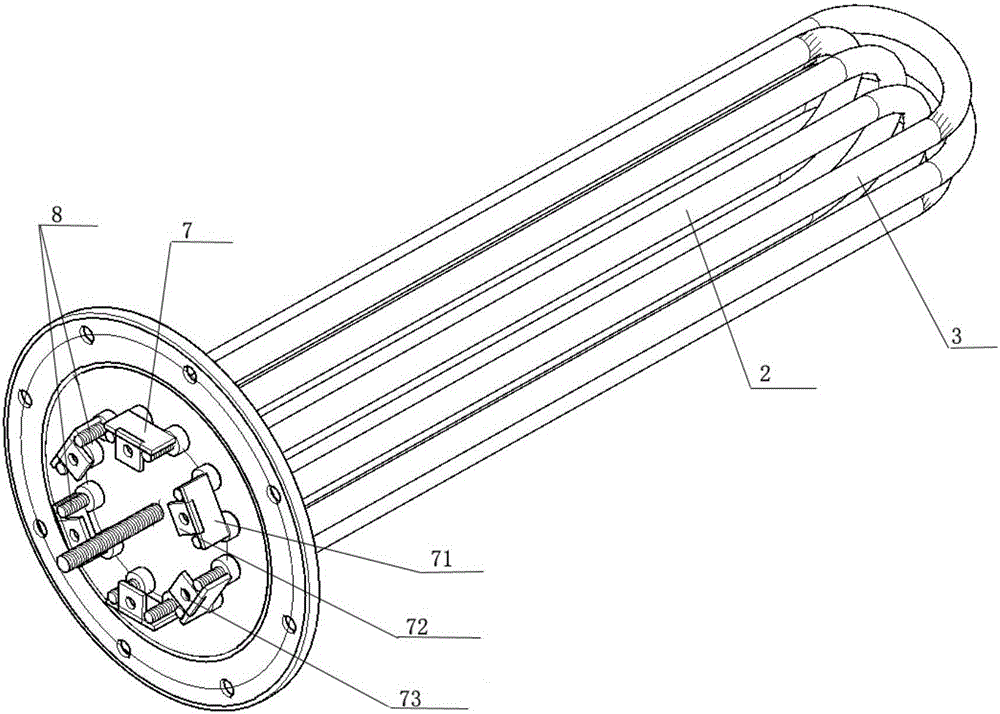

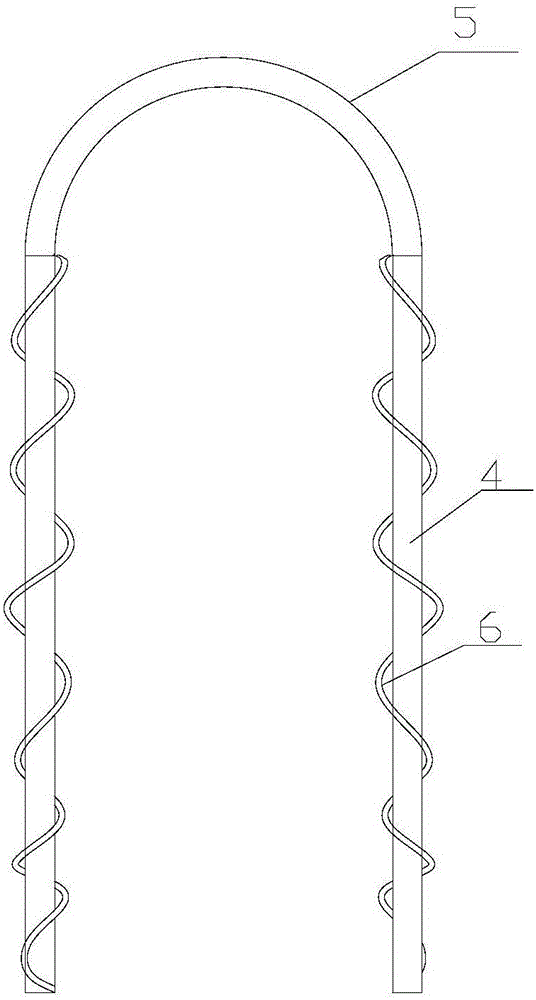

[0022] like figure 1 As shown, the flange heating tube includes a flange plate 1, a first electric heating tube 2 and a second electric heating tube 3, and the first electric heating tube 2 and the second electric heating tube 3 are composed of two vertical sections 4, one connecting two The transition section 5 of the vertical section is composed of the end of the vertical section (that is, the end of the first electric heating tube and the end of the second electric heating tube) passing through the flange 1, and the first electric heating tube and the second electric heating tube are independently arranged and cross each other , the first electric heating tube is arranged below the second electric heating tube, and the height of the transition section of the second electric heating tube 3 is higher than the height of the transition section of the first electric heating tube 1 .

[0023] The two vertical sections and the transition section can be integrally formed.

[0024]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com