A kind of gel polymer electrolyte membrane and its preparation method and application

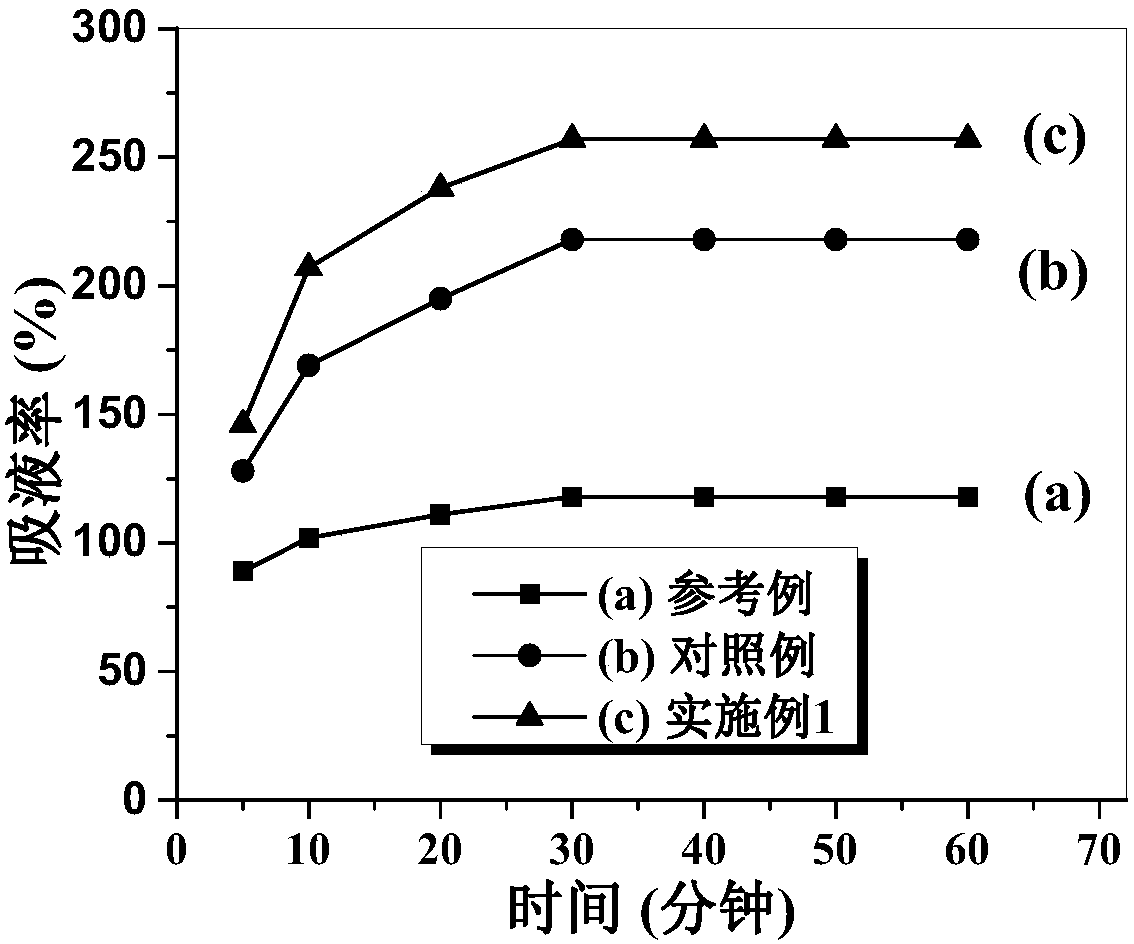

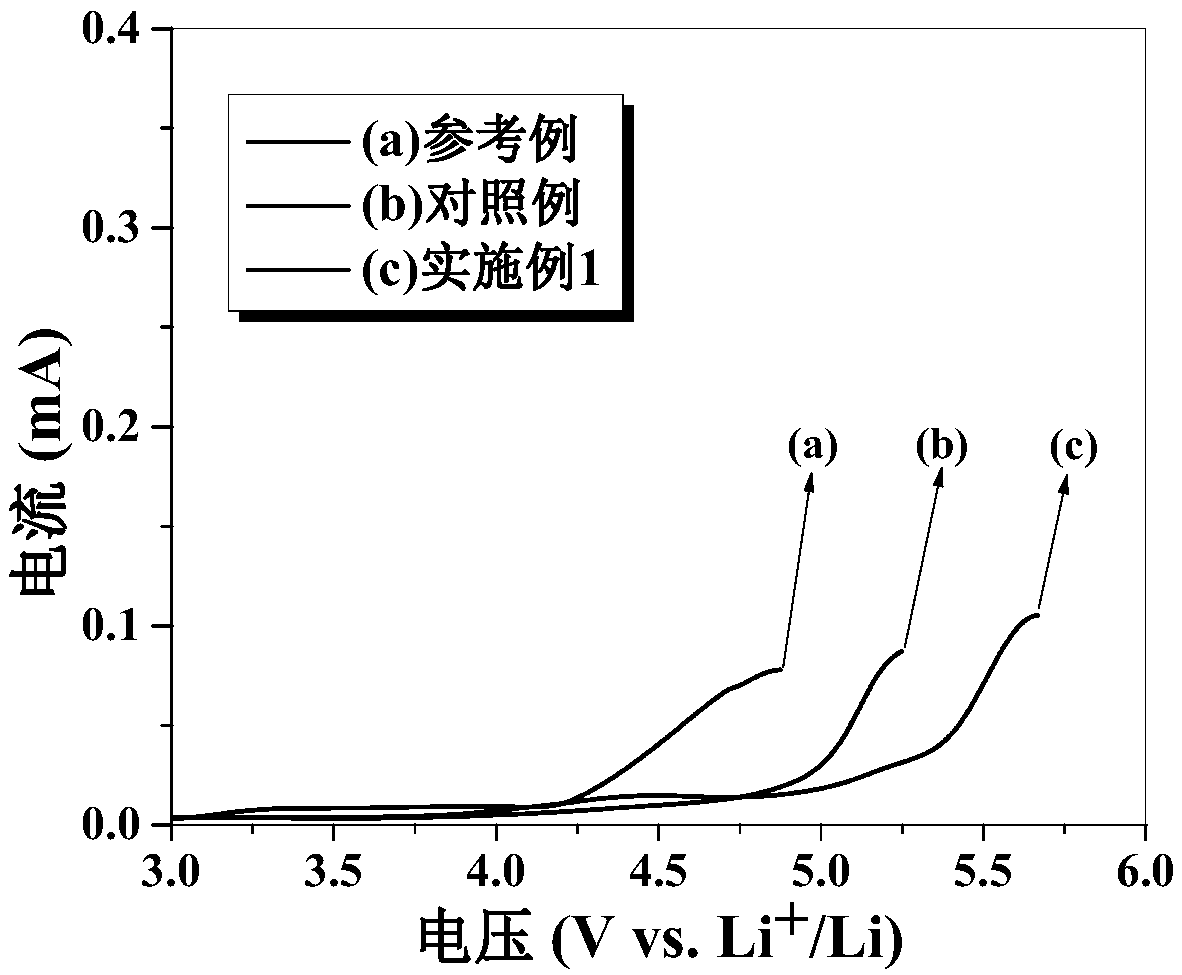

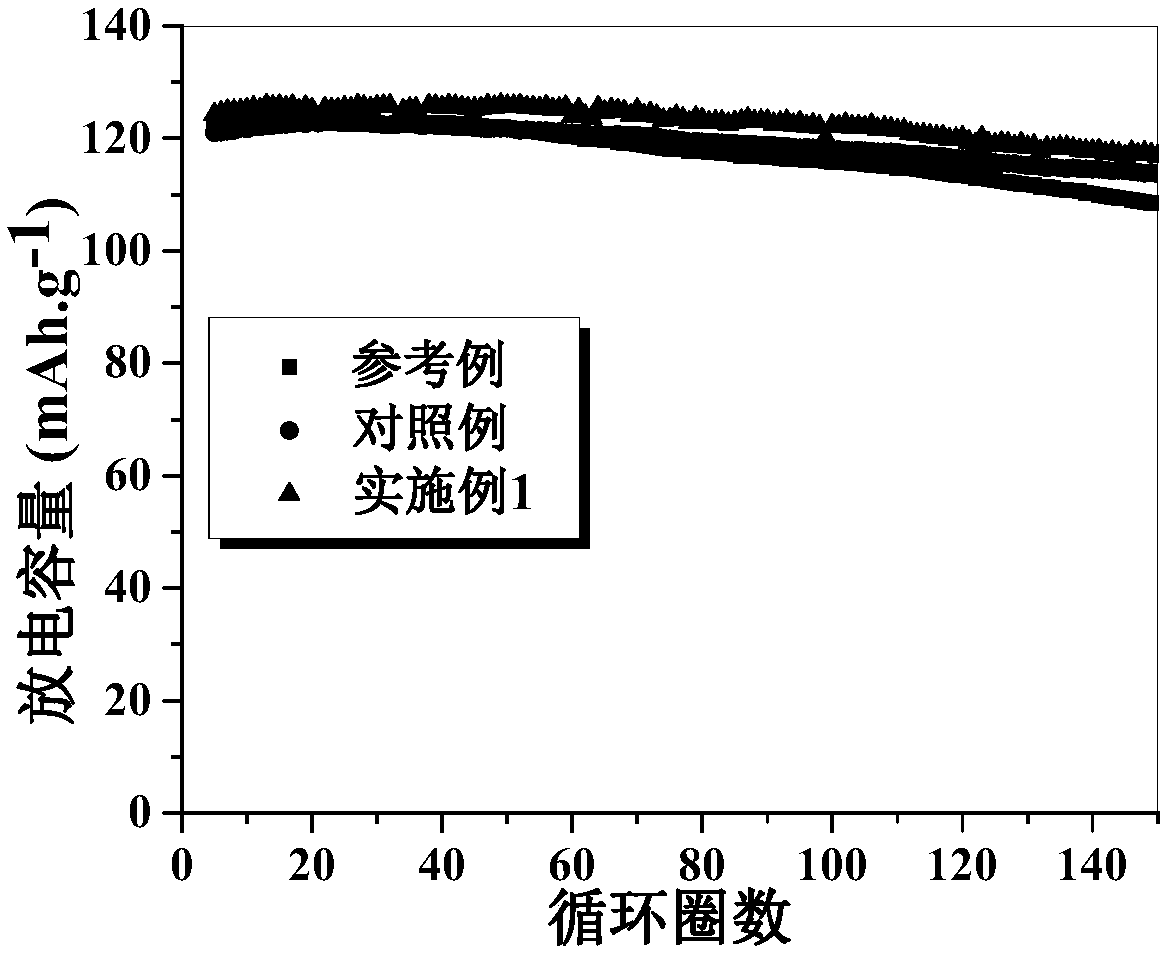

A gel polymer, electrolyte separator technology, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problem of unsatisfactory electrochemical stability window, unsatisfactory ionic conductivity, and narrow applicable temperature range, etc. It can improve the ionic conductivity and electrochemical stability window, facilitate the promotion and application of industrialization, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) in N 2 Under the protection of protective atmosphere, add 1.48% emulsifier sodium lauryl sulfate into 68.86% deionized water, stir mechanically for 20 minutes to fully dissolve it, then add 29.51% monomer n-butyl methacrylate, propylene Nitrile and styrene (where the mass ratio of n-butyl methacrylate, acrylonitrile and styrene is 1:2:1), raise the temperature to 60°C, and stir mechanically for 20 minutes to make it evenly mixed. Then the stirrer speed was adjusted to 800r / min, and at the same time, 0.15% initiator sodium persulfate was slowly added dropwise with a constant pressure funnel, and the initiator was added in 30 minutes. After 8 hours of reaction, an egg white-like white emulsion was obtained, and the emulsion was poured into 3% Al 2 (SO 4 ) 3 Stir the solution in a beaker to break the emulsion (where Al 2 (SO 4 ) 3The solvent quality of the solution is equal to the total mass of the emulsion), and then repeatedly washed with deionized water and ab...

Embodiment 2

[0042] (1) Under the protection of Ar protective atmosphere, add 1% of emulsifier potassium lauryl sulfate to 72% deionized water, mechanically stir for 30 minutes to fully dissolve it, and then add 26.9% of monomeric methacrylic acid n-butyl ester, acrylonitrile and styrene (the mass ratio of n-butyl methacrylate, acrylonitrile and styrene is 1:1:1), raise the temperature to 55°C, stir mechanically for 20 minutes to make it evenly mixed . Then adjust the speed of the agitator to 900r / min, and slowly add 0.1% of the initiator potassium persulfate dropwise with a constant pressure funnel, and control the addition of the initiator within 30 minutes. After 8 hours of reaction, an egg white-like white emulsion was obtained, and the emulsion was poured into 2% Al 2 (SO 4 ) 3 Stir the solution in a beaker to break the emulsion (where Al 2 (SO 4 ) 3 The solvent quality of the solution is equal to the total mass of the emulsion), and then repeatedly washed with deionized water a...

Embodiment 3

[0047] (1) Under the protection of Ar protective atmosphere, add 4% emulsifier ammonium lauryl sulfate to 60% deionized water, stir it mechanically for 40 minutes to fully dissolve it, then add 35.6% monomeric methacrylic acid n-butyl ester, acrylonitrile and styrene (the mass ratio of n-butyl methacrylate, acrylonitrile and styrene is 2:1:4), raise the temperature to 65°C, stir mechanically for 40 minutes to make it evenly mixed . Then the stirrer speed was adjusted to 900r / min, and at the same time, 0.4% initiator ammonium persulfate was slowly added dropwise with a constant pressure funnel, and the initiator was controlled to be added within 30 minutes. After 10 hours of reaction, an egg white-like white emulsion was obtained, and the emulsion was poured into 5% Al 2 (SO 4 ) 3 Stir the solution in a beaker to break the emulsion (where Al 2 (SO 4 ) 3 The solvent quality of the solution is equal to the total mass of the emulsion), and then repeatedly washed with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com