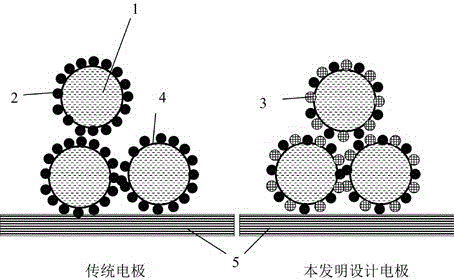

Preparation method of improved room temperature electron ion fast transfer electrode slice for solid-state secondary lithium battery

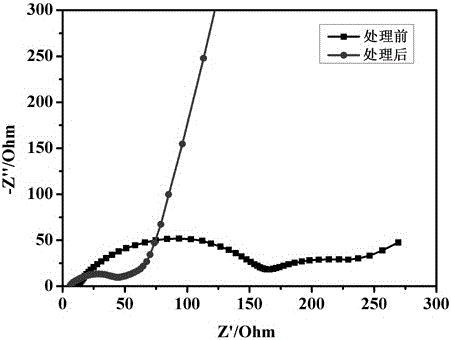

A secondary lithium battery, fast transmission technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems that are not conducive to reducing the transmission time of lithium ions, low lithium ion conductivity, long average migration path, etc. Achieve the effects of improving energy density and rate performance, increasing transmission rate, and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

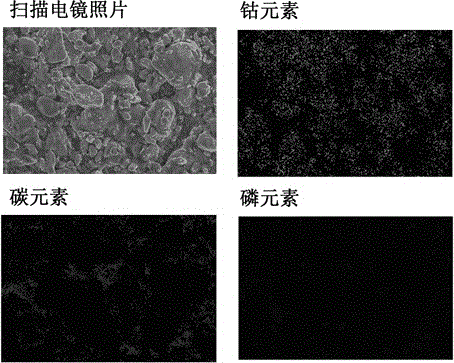

Embodiment 1

[0035] 8 g LiCoO 2 , 0.5 g acetylene black and 0.5 g Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Grind for 1 h, then add 1.0 g of polyvinylidene fluoride binder (polyvinylidene fluoride is dissolved in N-methylpyrrolidone, the mass fraction is 15%) and continue grinding for 0.5-1 h to obtain a uniform slurry; The method is to apply the slurry on the surface of aluminum foil, and then place it in a 60 °C oven to dry for 6 hours; roll the dried pole pieces, cut them, weigh them, and then place them in a 120 °C vacuum oven for 12 hours. , transferred to a nitrogen-filled glove box to obtain LiCoO 2 Positive sheet.

Embodiment 2

[0037] 8 gLiFePO 4 , 0.2 g acetylene black and 0.8 g LiZr 2 (PO 4 ) 3 Grind for 1 h, then add 1.0 g of sodium alginate-poly-3,4-propylenedioxythiophene-2,5-dicarboxylic acid (SA-PProDOT for short) binder (SA-ProDOT dissolved in N-methylpyrrolidone , with a mass fraction of 40%) continued to grind for 0.5-1 h to obtain a uniform slurry; the slurry was coated on the surface of aluminum foil by scraping, and then dried in an oven at 60 °C for 6 h; the dried The pole pieces were rolled, cut and weighed, then dried in a vacuum oven at 120 °C for 12 h, and transferred to a nitrogen-filled glove box to obtain LiFePO 4 Positive sheet.

Embodiment 3

[0039] 9 g graphite, 0.1 g superconducting carbon black and 0.4 g Li 7 La 3 Zr 2 o 12 Grind for 1 h, then add 0.5 g of polytetrafluoroethylene binder (an emulsion composed of 98% polytetrafluoroethylene and 2% carboxymethyl cellulose, the mass fraction is 60%) and continue grinding for 0.5-1 h to obtain a uniform the slurry; the slurry was coated on the surface of the aluminum foil by scraping, and then dried in an oven at 60 °C for 6 h; the dried pole piece was rolled, cut, weighed, and then placed at 120 °C in a vacuum oven for 12 h, then transferred to a nitrogen-filled glove box to obtain a graphite negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com