High-thermal-conductivity insulating medium fast-heating cathode hot wire assembly and preparation method thereof

A technology of insulating medium and heating wire assembly, which is applied in the field of indirect heating fast heating cathode, can solve the problems of reducing reliability and service life, limiting the heating rate of cathode, insufficient high temperature strength, etc., and achieves short preheating time and high shock resistance. , the effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

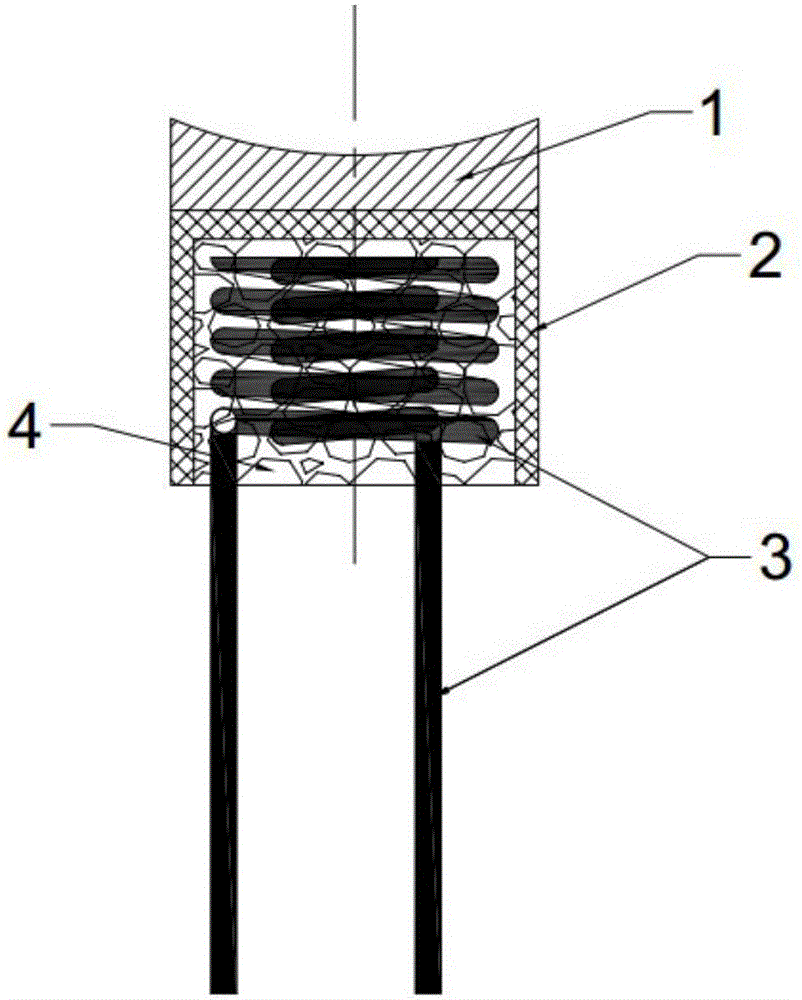

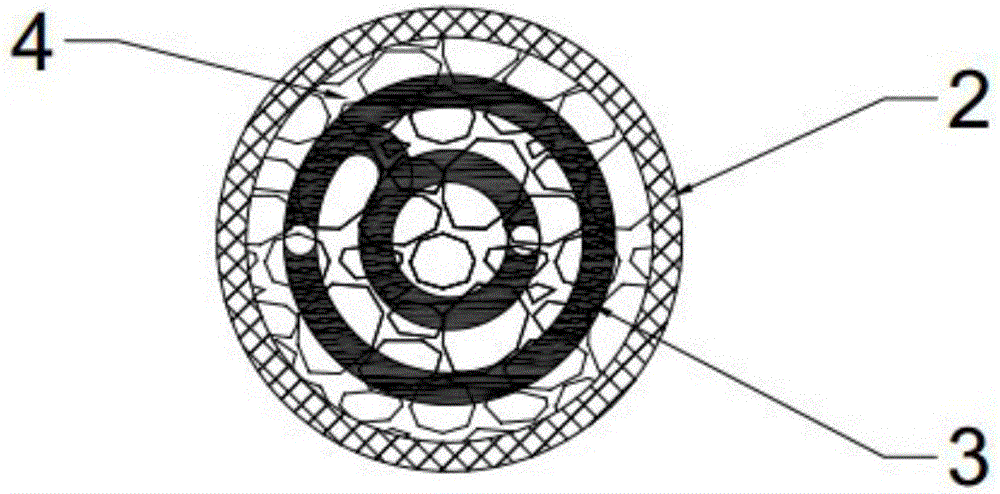

Image

Examples

Embodiment 1

[0021] 1. The high-purity AlN powder is pre-fired at a high temperature of 800°C for 5 hours, crushed by a jet mill, and sieved with an air vibrating sieve to obtain a powder of 5-10 μm;

[0022] 2. Mix collodion solution dissolved in ethanol and ether mixture with AlN powder, and add 2% Y 2 o 3 Powder and 2% CaF 2 Powder, ball milling to obtain a slurry with good fluidity;

[0023] 3. After vacuum degassing, the slurry is poured into the cathode cylinder, and then the tungsten-rhenium alloy hot wire with a rhenium element mass fraction of 20-25% is slowly put into the cathode cylinder containing the slurry, and the speed is 5000r / min along the axis of the cathode cylinder Centrifuge for 5 minutes, put it into a drying oven and dry for 2 hours at a drying temperature of 60°C.

[0024] 4. Put the hot wire and cathode cylinder assembly prepared in the previous step into a tungsten wire furnace at a sintering temperature of 1800°C, sintering in a hydrogen, nitrogen or argon at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com