Flexible fabric switch

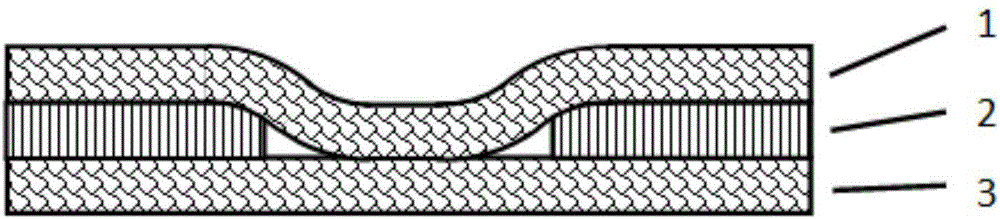

A flexible fabric and switch technology, applied in the field of wearable electronic devices, can solve the problems of poor shear resistance, limited life, short life, etc., achieve improved stability and fatigue resistance, adjustable conduction pressure, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned flexible fabric switch comprises the following steps:

[0029] a) compounding the elastic isolation layer and the adhesive layer;

[0030] b) cutting or punching through holes with a knife on the composite elastic isolation layer;

[0031] c) the upper conductive layer and the lower conductive layer are respectively connected to conductive wires;

[0032] d) Composite the elastic isolation layer with the upper conductive layer and the lower conductive layer respectively through the adhesive layer.

Embodiment 1

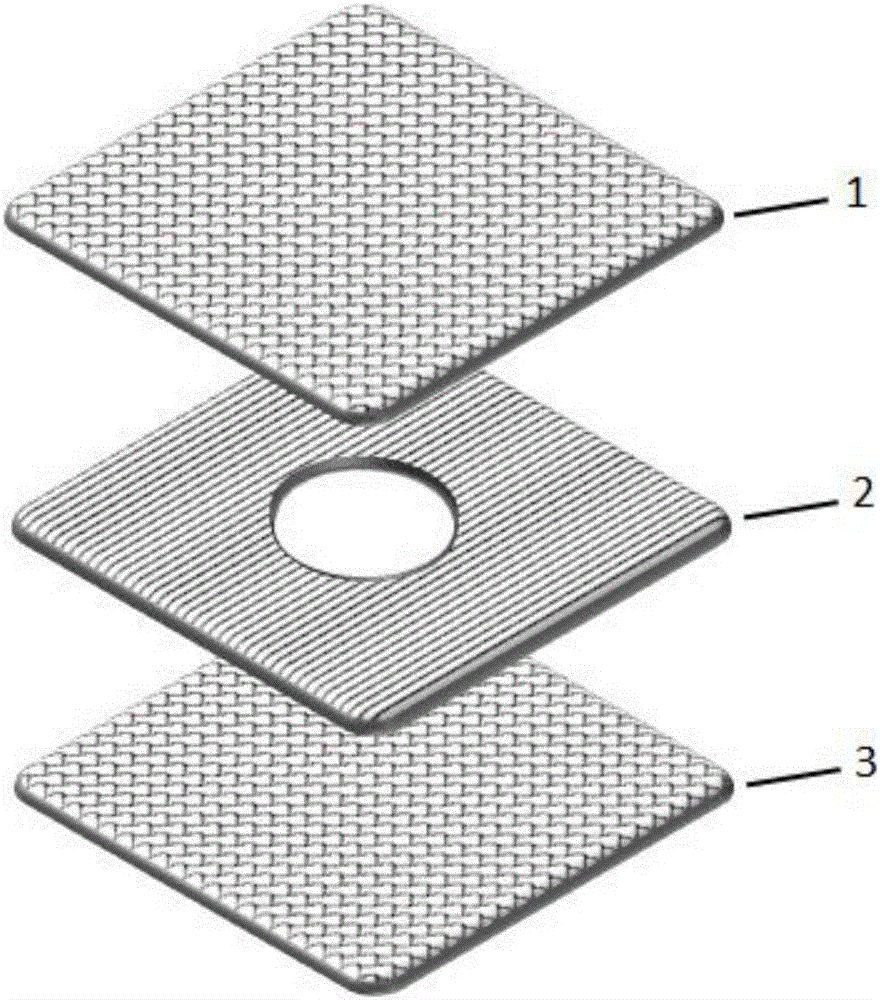

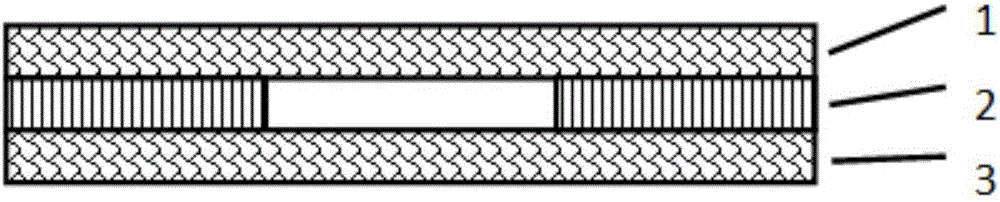

[0034] A flexible fabric switch comprises an upper conductive layer, a lower conductive layer, and an elastic isolation layer arranged between the upper conductive layer and the lower conductive layer, and is compounded by an adhesive layer. The upper conductive layer and the lower conductive layer are made of silver-plated fiber conductive fabric; the elastic isolation layer is made of warp-knitted elastic knitted fabric woven from polyurethane filaments, and a single circular through hole is cut in the middle of the elastic isolation layer; the adhesive layer is selected from thermal insulation. Melted TPU film.

[0035] The preparation method of the flexible fabric switch in this embodiment comprises the following steps:

[0036] a) The elastic knitted fabric and the hot-melt TPU film are combined and bonded by hot pressing, and the middle is elastic knitted

[0037] Cloth, with hot-melt TPU film on the top and bottom, made of elastic isolation layer;

[0038] b) cutting ...

Embodiment 2

[0042] A flexible fabric switch comprises an upper conductive layer, a lower conductive layer, and an elastic isolation layer arranged between the upper conductive layer and the lower conductive layer, and is compounded by an adhesive layer. Copper-plated fiber conductive fabric is used for the upper conductive layer and the lower conductive layer; the elastic isolation layer is made of silica gel, and three circular through holes are cut in the middle of the elastic isolation layer; acrylic adhesive is selected for the adhesive layer.

[0043] The preparation method of the flexible fabric switch in this embodiment comprises the following steps:

[0044] a) bonding the elastic release layer with an acrylic adhesive;

[0045] b) using a laser cutting machine to cut out three circular through holes in the composite elastic isolation layer;

[0046] c) The upper conductive layer and the lower conductive layer are respectively connected to the upper silver-plated fiber conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com