Rotary jet flow PDC drill bit

A drill bit and jet technology, applied in drill bits, drill pipes, drill pipes, etc., can solve the problems of secondary wear and reduced work efficiency, and achieve the effects of increasing the ROP, prolonging the service life, and reducing the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

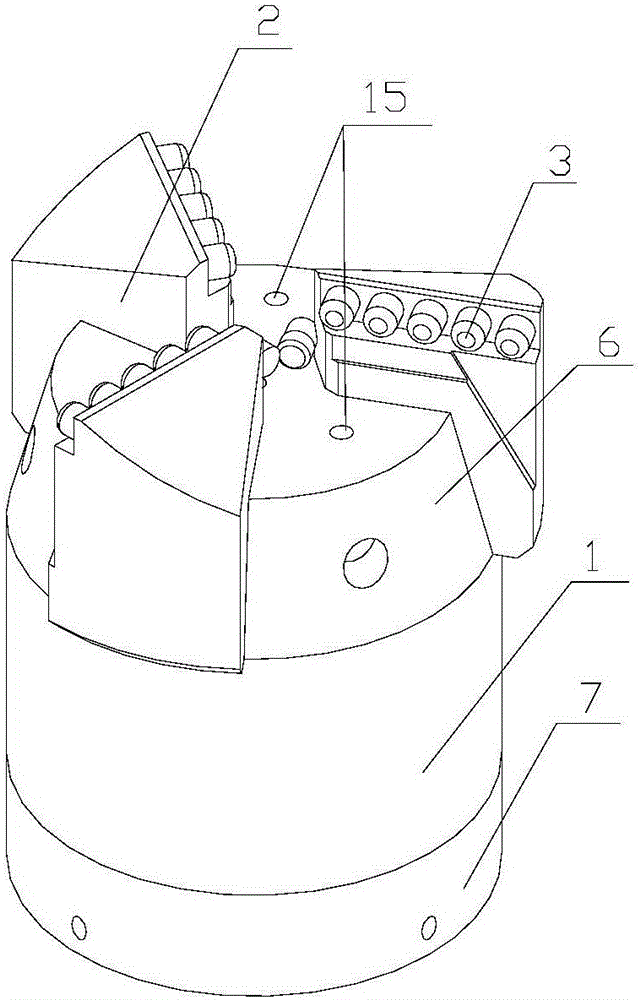

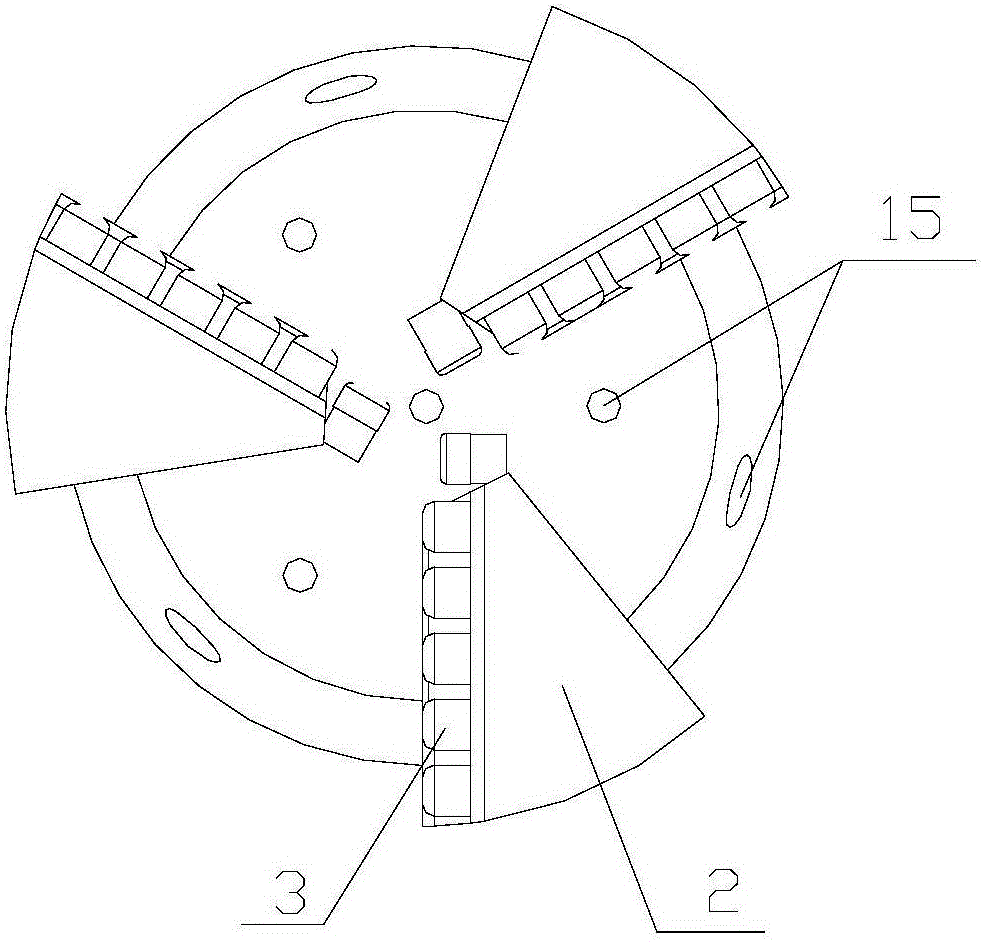

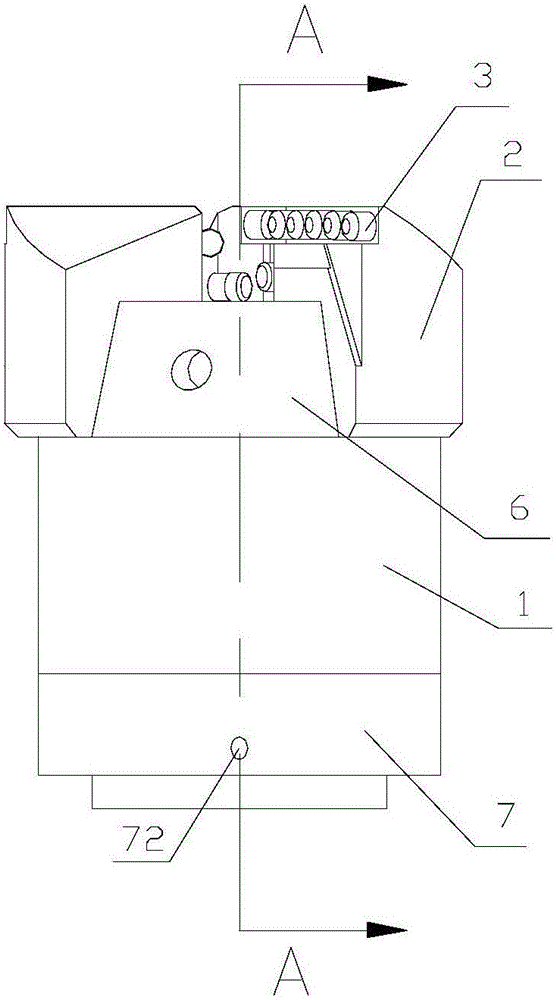

[0025] Such as Figure 1-2 As shown, a rotary jet PDC drill bit of the present invention includes a drill body 1, a blade 2, a PDC cutting tooth 3, a nozzle, a runner, a chip flute 6 and a reverse nozzle joint 7, and the blade 2 is arranged on the drill body 1 In the crown, the PDC cutters 3 are arranged on the blade 2. The flow channel 5 runs through the drill body 1 and the reverse nozzle joint 7. The drill body 1 drives the blade 2 to rotate, and the PDC cutters 3 cut the rock formation. The high-pressure jet of the channel washes away the residual cuttings, and finally completes the entire drilling operation.

[0026] The structure and principle of the present invention will be described in detail below.

[0027] Such as Figure 1-4 As shown, the present invention provides a rotary jet PDC bit (PDC is Polycrystalline Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com