Turbo-type underground hydraulic oscillator

A hydraulic oscillator and turbine-type technology, which is applied in vibration drilling, wellbore/well components, vibration generating devices, etc., can solve problems such as affecting the mechanical drilling speed, increasing frictional resistance, and reducing the efficiency of WOB transmission. To achieve the effect of long service life, small bearing load and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

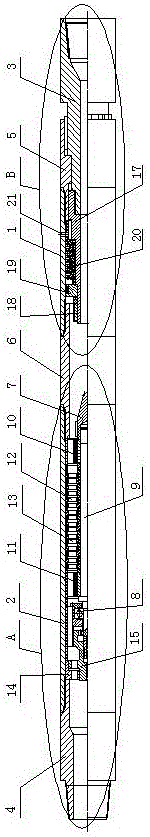

[0021] The turbine downhole hydraulic oscillator includes an upper casing 1 , a lower casing 2 , an upper joint 3 , a lower joint 4 , a spline sleeve 5 and an intermediate joint 6 . The upper shell 1 and the lower shell 2 are screwed to each other through the intermediate joint 6, the end of the lower shell 2 is threaded with the lower joint 4, and the end of the upper shell 1 is threaded with the upper joint through the spline sleeve 5 3; Threaded connection between the upper housing 1 and the spline sleeve 5 .

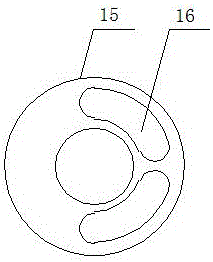

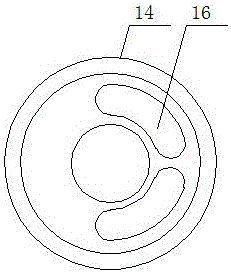

[0022] The turbine shaft 9 is installed in the lower housing 2 through the turbine shaft end cap 7 and the thrust bearing 8, and the turbine assembly is installed on the turbine shaft 9 through the centralizing bearing A10 and the centralizing bearing B11. The turbine assembly consists of a turbine stator 12 and a rotor 13 which are sequentially mounted on a turbine shaft 9 . The righting bearing A10 is threadedly fixed to the turbine shaft 9 through the turbine sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com