Automatic sliding well drilling control device

A sliding drilling and control device technology, which is applied to the automatic control system of drilling, drilling equipment, directional drilling, etc., can solve the problems of low wellbore purification efficiency, easy motor stall, high cost, etc., to improve the quality of wellbore trajectory, The effect of increasing the ROP and increasing the drilling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and embodiments.

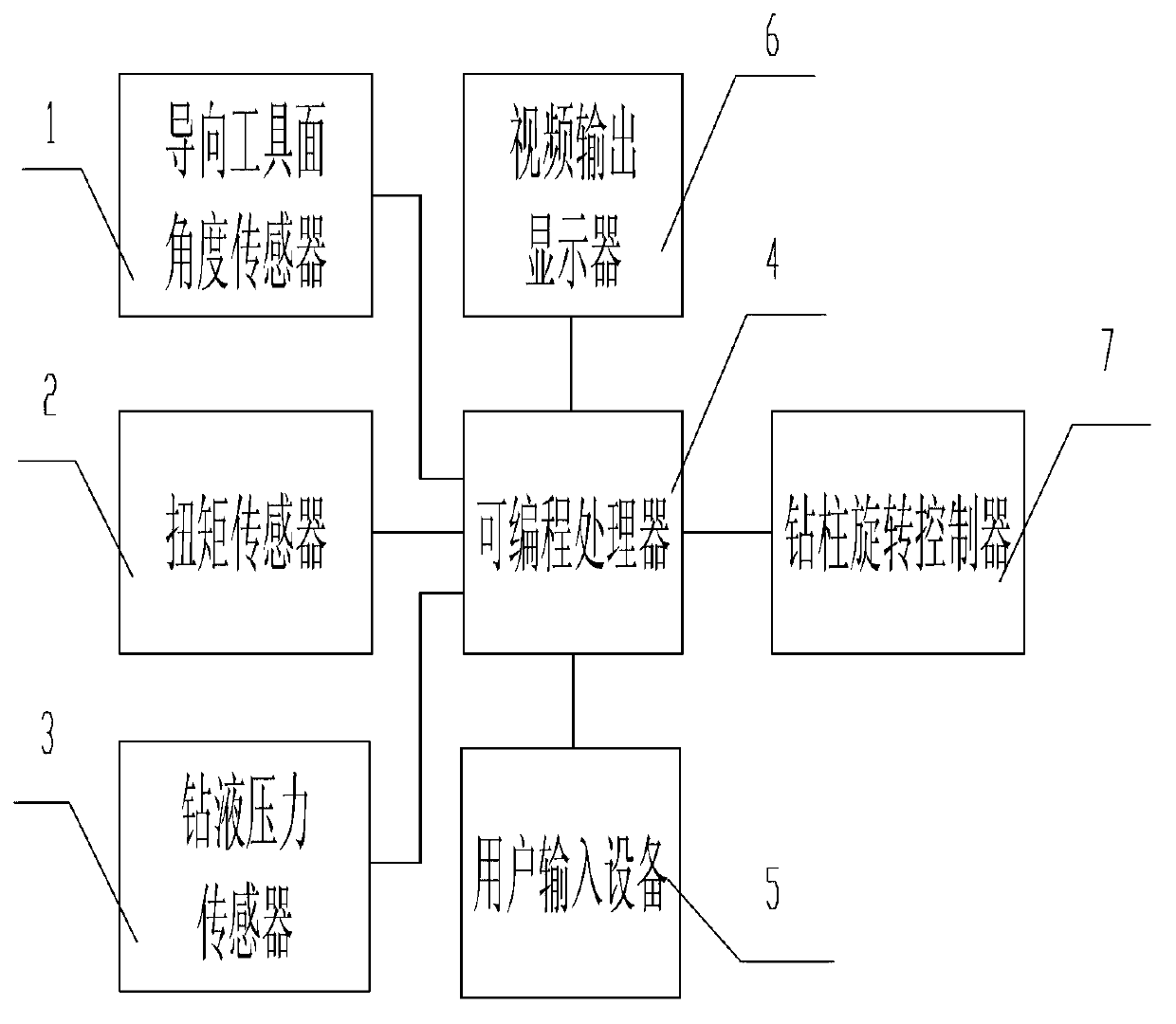

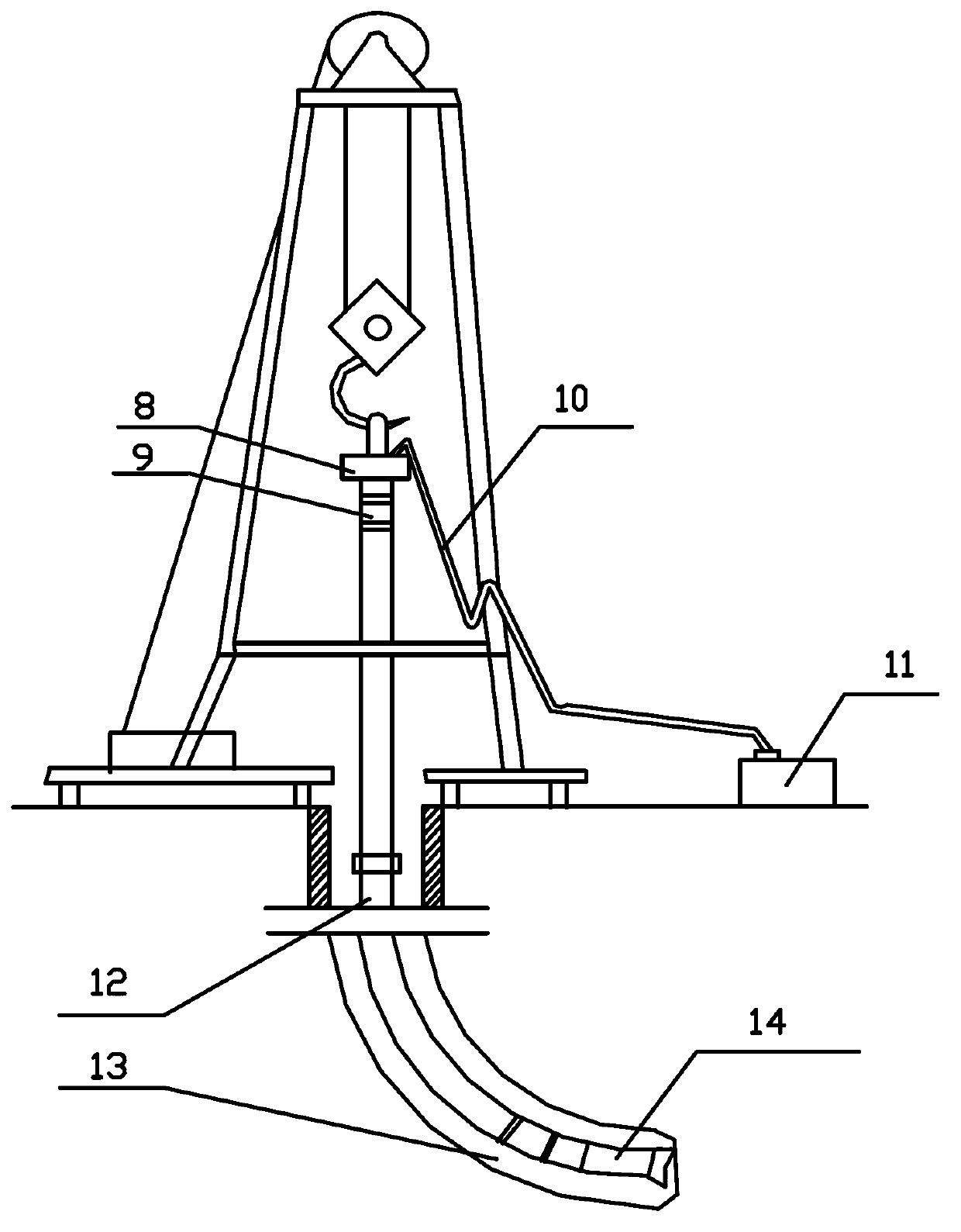

[0012] The automatic sliding drilling control device of the present invention is composed of a steering tool face angle sensor 1, a torque sensor 2, a drilling fluid pressure sensor 3, a programmable processor 4, a user input device 5, a video output display 6, and a drill string rotation controller 7; The above-mentioned steering tool face angle sensor 1 is installed in the bottom hole assembly 13. The steering tool face angle sensor 1 uses mud pulse telemetry to send a signal to the receiver on the ground, and the ground receiver outputs a steering tool face angle signal for transmission. to the programmable processor 4 for processing; the steering tool face angle signal is generated at a rate of once every 20 seconds, which is an indication signal used to measure the tool face angle of the steerable drilling motor 14; the torque sensor 2 is installed I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com