Preparation method of cotton-linen blended yarn containing infrared heating fibers

A technology of heating fibers and blended yarns, applied in fiber processing, biochemical fiber processing, yarn and other directions, can solve problems such as poor quality control, difficulty in yarn and fabric production, affecting people's sleep quality, etc. Good uniformity, less impurity content, and the effect of increasing comfort and tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

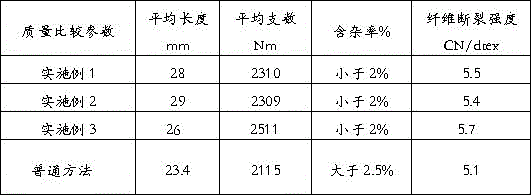

Examples

Embodiment 1

[0043] A preparation method of the hemp-cotton blended yarn containing infrared heating fibers of the present invention comprises the following steps: (1) blending the prepared hemp-cotton blending functional fibers and infrared heating fibers in proportion, plying and twisting to obtain The hemp-cotton blended yarn of infrared heating fiber is mixed and assembled, spun into raw roving and then boiled and bleached through roving;

[0044] The preparation steps of hemp-cotton blended functional fiber are:

[0045] Soak hemp fiber, apocynum husk, and cotton fiber in acetone, perform ultrasonic shock treatment at the same time, dehydrate and dry after washing to obtain mixed fiber; mix mixed fiber and cotton fiber in proportion and twist to form mixed yarn; Wherein, the mass ratio of described hemp fiber, apocynum husk and cotton fiber is 2:2:1;

[0046] The preparation steps of the infrared heating fiber are as follows: the flax fiber and the infrared heating fiber silk are ble...

Embodiment 2

[0062] The difference between embodiment 2 and embodiment 1 is: a kind of preparation method of the hemp-cotton blended yarn containing infrared heating fiber of the present invention, comprises the following steps:

[0063] In step (1), the prepared hemp-cotton blended functional fibers and infrared heating fibers are blended in proportion, and twisted to obtain hemp-cotton blended yarns containing infrared heating fibers. After mixing and matching, they are spun into raw After roving, the roving is boiled and bleached;

[0064] The preparation steps of hemp-cotton blended functional fiber are:

[0065] Soak hemp fiber, apocynum husk, and cotton fiber in acetone, perform ultrasonic shock treatment at the same time, dehydrate and dry after washing to obtain mixed fiber; mix mixed fiber and cotton fiber in proportion and twist to form mixed yarn; Wherein, the mass ratio of described hemp fiber, apocynum husk and cotton fiber is 5:4:1;

[0066] The preparation steps of the inf...

Embodiment 3

[0081] The difference between Example 3 and Example 1 is that a method for preparing a hemp-cotton blended yarn containing infrared heating fibers of the present invention comprises the following steps:

[0082] In step (1), the prepared hemp-cotton blended functional fibers and infrared heating fibers are blended in proportion, and twisted to obtain hemp-cotton blended yarns containing infrared heating fibers. After mixing and matching, they are spun into raw After roving, the roving is boiled and bleached;

[0083] The preparation steps of hemp-cotton blended functional fiber are:

[0084] Soak hemp fiber, apocynum husk, and cotton fiber in acetone, perform ultrasonic shock treatment at the same time, dehydrate and dry after washing to obtain mixed fiber; mix mixed fiber and cotton fiber in proportion and twist to form mixed yarn; Wherein, the mass ratio of described hemp fiber, apocynum husk and cotton fiber is 3:3:1;

[0085] The preparation steps of the infrared heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com