Biology base polymer aerogel oil absorption material and preparation method thereof

A bio-based polymer, oil-absorbing material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low oil quality adsorption capacity, no oil-water selectivity, etc., and achieve excellent compression recovery and high adsorption. Capacity retention, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

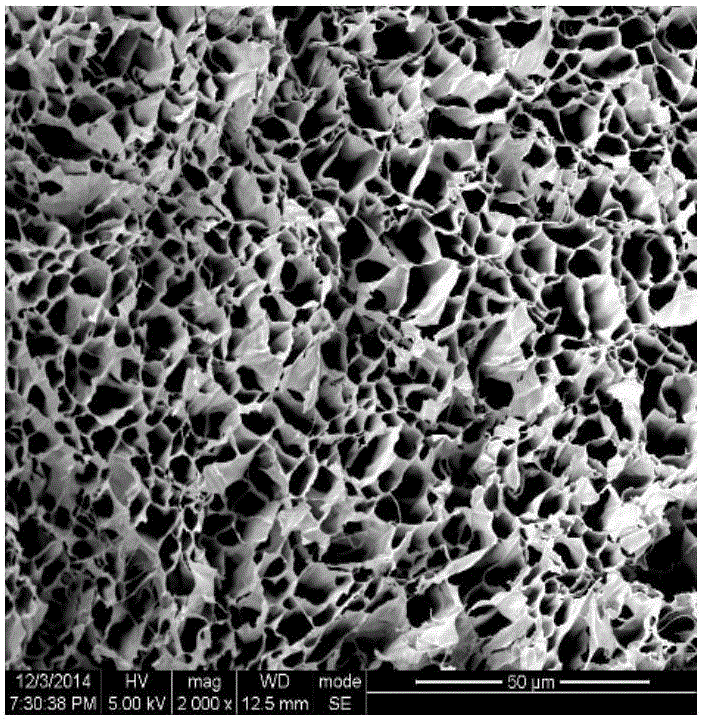

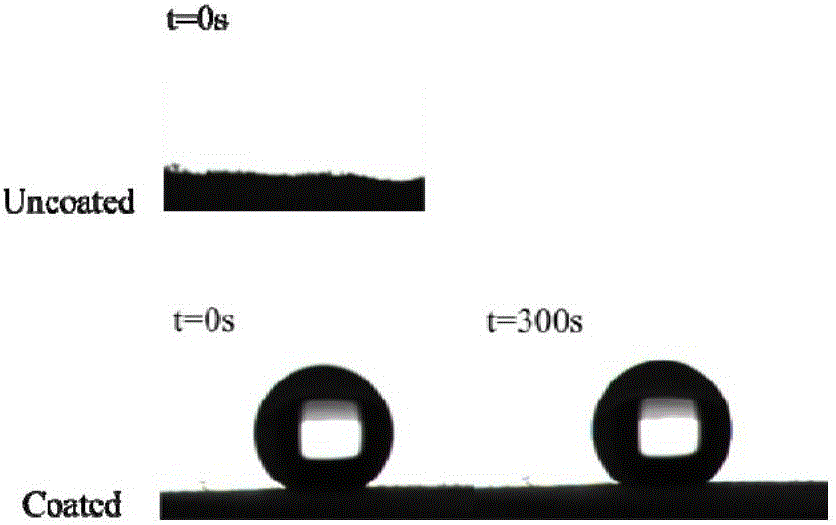

[0040] Add 0.3 parts of propylene glycol alginate to 100 parts of water, heat and stir to dissolve it completely, then add 0.03 parts of hexamethylene diisocyanate, and stir and react at 25°C for 6 hours; pre-freeze the obtained precursor solution at 10°C 12h, and then completely freeze it into a solid at -196°C, and then dry the solid at -20°C for 120h to obtain an airgel; °C for hydrophobic modification for 12 hours to obtain a bio-based polymer airgel super oil-absorbing material.

[0041] The relevant performance test results of the oil-absorbing material are shown in the attached table.

Embodiment 2

[0043] Add 1.0 part of propylene glycol alginate to 100 parts of water, heat and stir to dissolve it completely, then add 0.1 part of hexamethylene diisocyanate, and stir and react at 25°C for 10 hours; pre-freeze the obtained precursor solution at 7°C 12h, and then completely freeze it into a solid at -196°C, and then dry the solid at -50°C for 192h to obtain an airgel; Hydrophobic modification was carried out at 100°C for 9 hours to obtain a bio-based polymer airgel super oil-absorbing material.

[0044] The relevant performance test results of the oil-absorbing material are shown in the attached table.

Embodiment 3

[0046] Add 2.0 parts of propylene glycol alginate to 100 parts of water, heat and stir to dissolve it completely, then add 0.2 parts of hexamethylene diisocyanate, and stir and react at 25°C for 12 hours; pre-freeze the obtained precursor solution at 6°C 12h, and then completely freeze it into a solid at -196°C, and then dry the solid at -20°C for 120h to obtain an airgel; °C for hydrophobic modification for 12 hours to obtain a bio-based polymer airgel super oil-absorbing material.

[0047] The relevant performance test results of the oil-absorbing material are shown in the attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com