Preparation method and application of hypercrosslinked resin with controllable polarity and pore structure

A technology of ultra-high cross-linked resin and pore structure, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., and can solve problems such as difficult control of pore size and complicated production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Preparation of precursor resin:

[0042] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. Add a total of 40 g of oil-o-xylene and benzyl alcohol, a total of 20 g of ethylene glycol dimethacrylate (EGDMA) and 4-vinylbenzyl chloride (VBC), and 0.2 g of azobisisobutyronitrile (AIBN). Heat to 45°C, adjust to a suitable stirring speed and stir for 30min, raise the temperature to 75°C for 2h, raise the temperature to 85°C for 3h, continue to raise the temperature to 95°C for 3h. After cooling, the resin was alternately washed with absolute ethanol, hot water, and cold water until the washing solution was clear, extracted with petroleum ether for 12 h in a Soxhlet extractor, and dried in vacuum for 24 h to obtain the precursor resin PEV-x-ab, (where , x is the mass percent of the crosslinking agent ethylene glycol dimethacrylate; a:b is the relative mass ratio of o-xylene and benzyl alcohol ...

Embodiment 2

[0048] 1) Preparation of precursor resin:

[0049] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. Add a total of 40g of oil ophthalmic xylene and benzyl alcohol, a total of 20g of 1,4-butanediol dimethacrylate (BDDMA) and 4-vinylbenzyl chloride (VBC), and 0.2g of azobisisobutyronitrile (AIBN) . Heat to 45°C, adjust to an appropriate stirring speed and stir for 30 minutes, raise the temperature to 75°C for 3 hours, raise the temperature to 85°C for 4 hours, and continue to raise the temperature to 95°C for 5 hours. After cooling, alternately wash the resin with absolute ethanol, hot water, and cold water until the washing liquid is clear, extract it with petroleum ether in a Soxhlet extractor for 12 hours, and dry it in vacuum for 24 hours to obtain the precursor resin PBV-x-ab: represented by x The crosslinking agent is 1,4 butanediol dimethacrylate by mass percentage, a:b is the relative ma...

Embodiment 3

[0055] 1) Preparation of precursor resin:

[0056] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. Add a total of 40 g of oil ophthalmic xylene and benzyl alcohol, a total of 20 g of glycerol dimethacrylate (PGDMA) and 4-vinylbenzyl chloride (VBC), and 0.2 g of azobisisobutyronitrile (AIBN). Heat to 45°C, adjust to a suitable stirring speed and stir for 30 minutes, raise the temperature to 75°C for 5 hours, raise the temperature to 85°C for 3 hours, and continue to raise the temperature to 95°C for 3 hours. After cooling, the resin was alternately washed with absolute ethanol, hot water, and cold water until the washing liquid was clear, extracted with petroleum ether in a Soxhlet extractor for 12 hours, and dried in vacuum for 24 hours to obtain the precursor resin PPV-x-ab.

[0057] 2) Friedel-Crafts reaction:

[0058] Add 15g of precursor resin PPV-10%-ab and 90mL of 1,2-dichloroethane int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

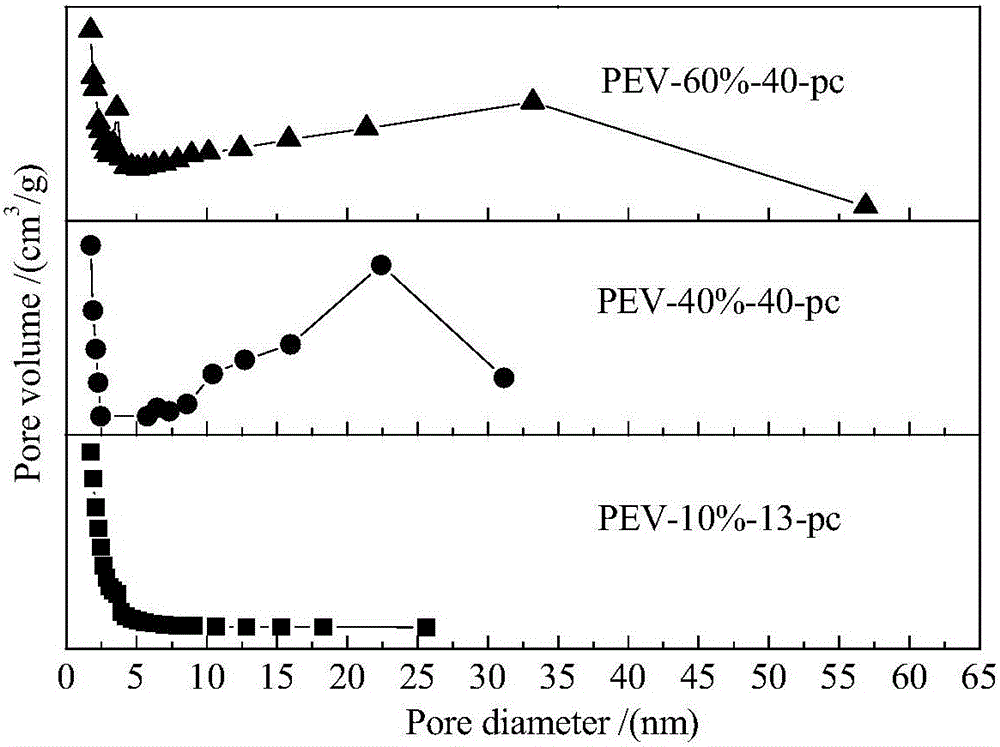

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com