Extraction method of L-citrulline in seed melon, and preparation method of effervescent tablet

An extraction method and citrulline technology, which are applied in the preparation of organic compounds, the preparation of urea derivatives, chemical instruments and methods, etc., can solve the problems of high residues of other amino acids, low product purity, difficult process control, etc. The agent is smooth and tidy, the process flow is short, and the effect of improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of L-citrulline effervescent tablet in seed melon, the method firstly provides a composition for effervescent tablet, and the composition includes the following components by weight:

[0060] 25-35 parts of L-citrulline, 17-21 parts of citric acid, 10-14 parts of mannitol, 2-4 parts of sucralose, 0.1-0.5 parts of steviol glycoside, PVP-k 30 4-6 parts of ethanol A solution;

[0061] 14-17 parts of sodium bicarbonate, 16-20 parts of mannitol, PVP-k 30 5-9 parts of ethanol B solution;

[0062] 0.6-1.0 parts of lemon essence, 1.8-2.5 parts of polyethylene glycol 6000;

[0063] L-citrulline is prepared according to the aforementioned extraction method of L-citrulline in seed melon, PVP-k 30 Ethanol A solution is PVP-k with a mass concentration of 90% 30 Ethanol solution, PVP-k 30 Ethanol B solution is the PVP-k that mass concentration is 20% 30 weak.

[0064] Commonly used fillers for preparing effervescent tabl...

Embodiment 1

[0084] A method for extracting L-citrulline in seed melon, comprising the steps of:

[0085] 1) Preparation of ultrafiltrate: squeeze the juice from the seeded melon pulp, centrifuge, and take the supernatant, vacuum filter the supernatant with a flat membrane with a pore size of 0.2um, and select the ultrafiltrate with a molecular weight cut-off of 5000 Daltons. Flat membrane ultrafiltration for 50 minutes, and then vacuum concentration until the mass concentration of L-citrulline was 4.0 mg / mL to obtain the ultrafiltrate;

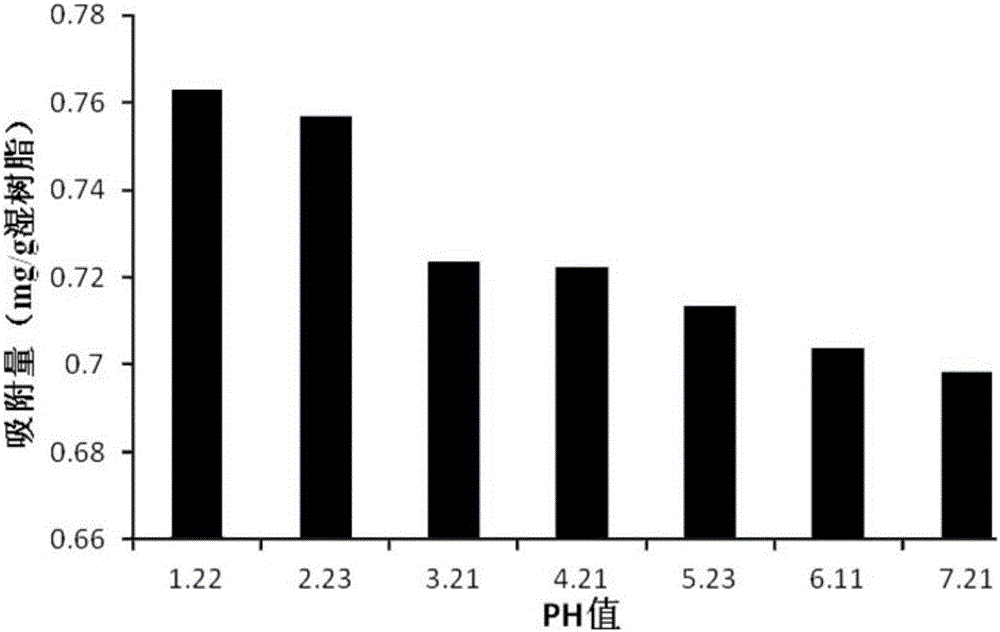

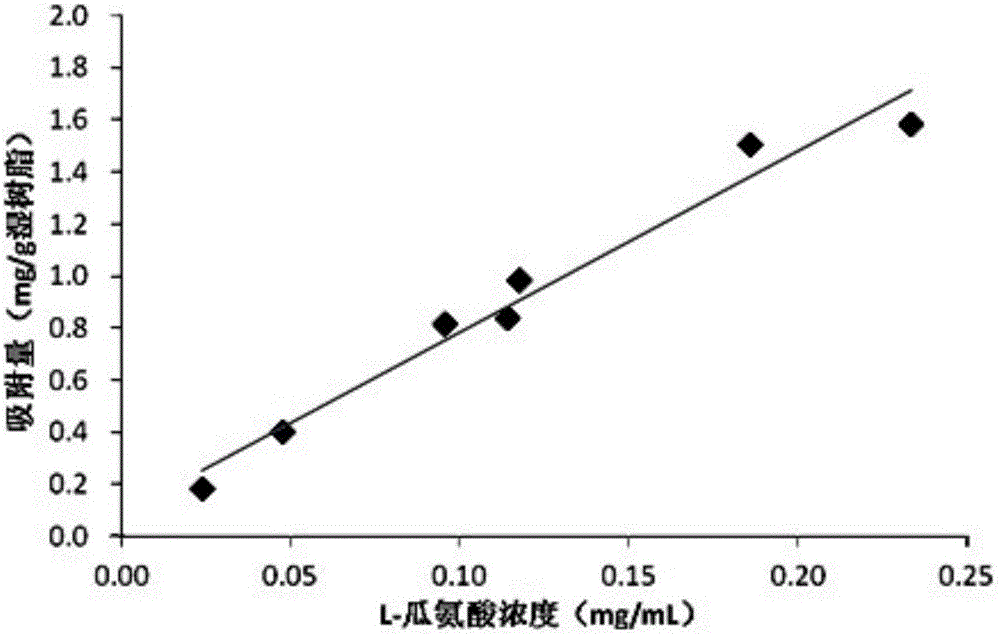

[0086] 2) Elution on the column: adjust the pH value of the ultrafiltrate to 1.2 to obtain the upper column liquid, pass the upper column liquid into the 732 type cation exchange resin with a loading capacity of 20ml to exchange and adsorb citrulline, and the flow rate through the column is 7.2BV / h, when the mass concentration of L-citrulline in the effluent is 4.0mg / mL, the adsorption is complete, and the ammonia water with a molar concentration of 0.6m...

Embodiment 2

[0096] A method for extracting L-citrulline in seed melon, comprising the steps of:

[0097] 1) Preparation of ultrafiltrate: squeeze the juice from the seeded melon pulp, centrifuge, and take the supernatant, vacuum filter the supernatant with a flat membrane with a pore size of 0.1um, and select the ultrafiltrate with a molecular weight cut-off of 7000 Daltons. Flat membrane ultrafiltration for 20 minutes, and then vacuum concentration until the mass concentration of L-citrulline was 3.0 mg / mL to obtain the ultrafiltrate;

[0098] 2) Elution on the column: adjust the pH value of the ultrafiltrate to 2.0 to obtain the upper column liquid, pass the upper column liquid into the 001×7 type cation exchange resin with a loading capacity of 25ml to exchange and adsorb citrulline, and the flow rate through the column is 3.6 BV / h, the adsorption is complete when the mass concentration of L-citrulline in the effluent is 3.0mg / mL, and the ammonia water with a molar concentration of 0.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com