Carbon-based rice seedling raising substrate for rice and preparation method thereof

A seedling-raising substrate and carbon-based technology, which is applied in planting substrates, botany equipment and methods, and the preparation of organic fertilizers, can solve problems such as environmental pollution and waste of resources, achieve large specific surface area, reduce leaching, and have a wide range of sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

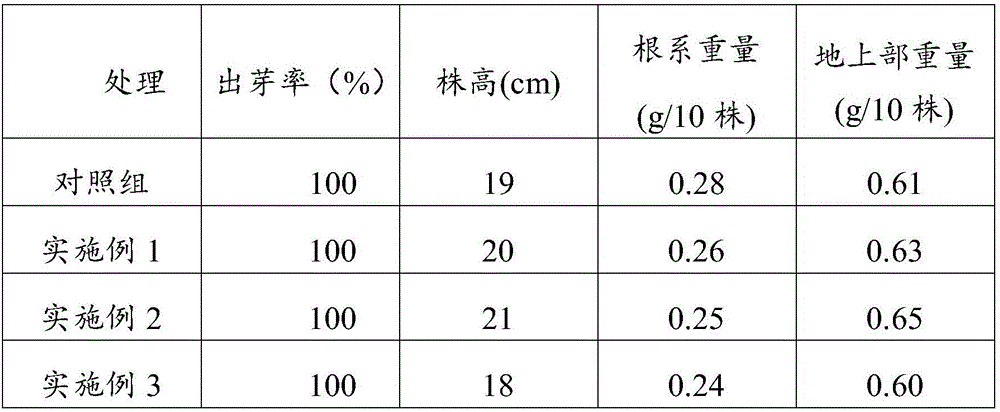

Examples

preparation example Construction

[0027] The invention also provides a preparation method of a rice charcoal-based seedling raising substrate, which comprises the following steps:

[0028] 1) Preparation of biochar: After the straw is crushed, it is dried in an oven and heated for 2-3 hours in a carbonization furnace at a temperature of 450-550°C and isolated from the air to obtain biochar particles, which is called biochar;

[0029] 2) Fermentation of straw fermented product: use rice husk and rice straw as raw materials, and the ratio of the two is 1:1 by volume. The raw materials are crushed to a powder with a particle size of about 0.5 to 1.0 cm. The quality of rice husk and straw In total, add 10%-20% of livestock manure (cow manure, pig manure, chicken manure, etc.), and then inoculate straw decomposing agent special bacteria and 5-10% paddy soil accumulation It is fermented, and the moisture content is controlled at 80%, and it is piled into the fermentation tank for fermentation. When the temperature rises,...

Embodiment 1

[0033] A preparation method of rice charcoal-based seedling raising substrate includes the following steps:

[0034] 1) Preparation of biochar: After the straw is crushed, it is dried in an oven and heated for 2.5 hours in a carbonization furnace at a temperature of 500°C and isolated from the air to obtain biochar particles, which is biochar;

[0035] 2) Fermentation of straw fermented product: use rice husk and rice straw as raw materials, and the ratio of the two is 1:1 by volume. The raw materials are crushed to a powder with a particle size of about 0.5 to 1.0 cm. The quality of rice husk and straw In total, add 10%-20% of livestock manure (cow manure, pig manure, chicken manure, etc.) with a mass percentage of 10% to 20%, and then inoculate straw decomposing agent special bacteria and 8% of paddy soil for accumulation and fermentation. Control the moisture content at 80%, pile it into the fermentation tank for fermentation, when the temperature rises, mechanically turn the pi...

Embodiment 2

[0039] A preparation method of rice charcoal-based seedling raising substrate includes the following steps:

[0040] 1) Preparation of biochar: After the straw is crushed, it is dried in an oven and heated for 3 hours in a carbonization furnace at a temperature of 450°C and isolated from the air to obtain biochar particles, namely biochar;

[0041] 2) Fermentation of straw fermented product: use rice husk and rice straw as raw materials, and the ratio of the two is 1:1 by volume. The raw materials are crushed to a powder with a particle size of about 0.5 to 1.0 cm. The quality of rice husk and straw In total, 10% of the mass percentage of livestock manure (can be cow manure, pig manure, chicken manure, etc.) is added, and then inoculated with special bacteria for straw composting agent and 10% of paddy soil accumulation and fermentation. With a moisture content of 80%, it is piled into the fermentation tank for fermentation. When the temperature rises, the pile is mechanically turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com