Attapulgite and biomass compound biological ceramsite and preparation method thereof

A technology of attapulgite and biological ceramsite, which is applied in the direction of clay products, ceramic products, chemical instruments and methods, etc., and can solve the problems of unsuitable promotion and application of biomass ceramsite, low utilization rate of rice husk, and high production cost. Achieve the effect of being conducive to bio-filming, increasing the microbial biomass of particle-filming, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

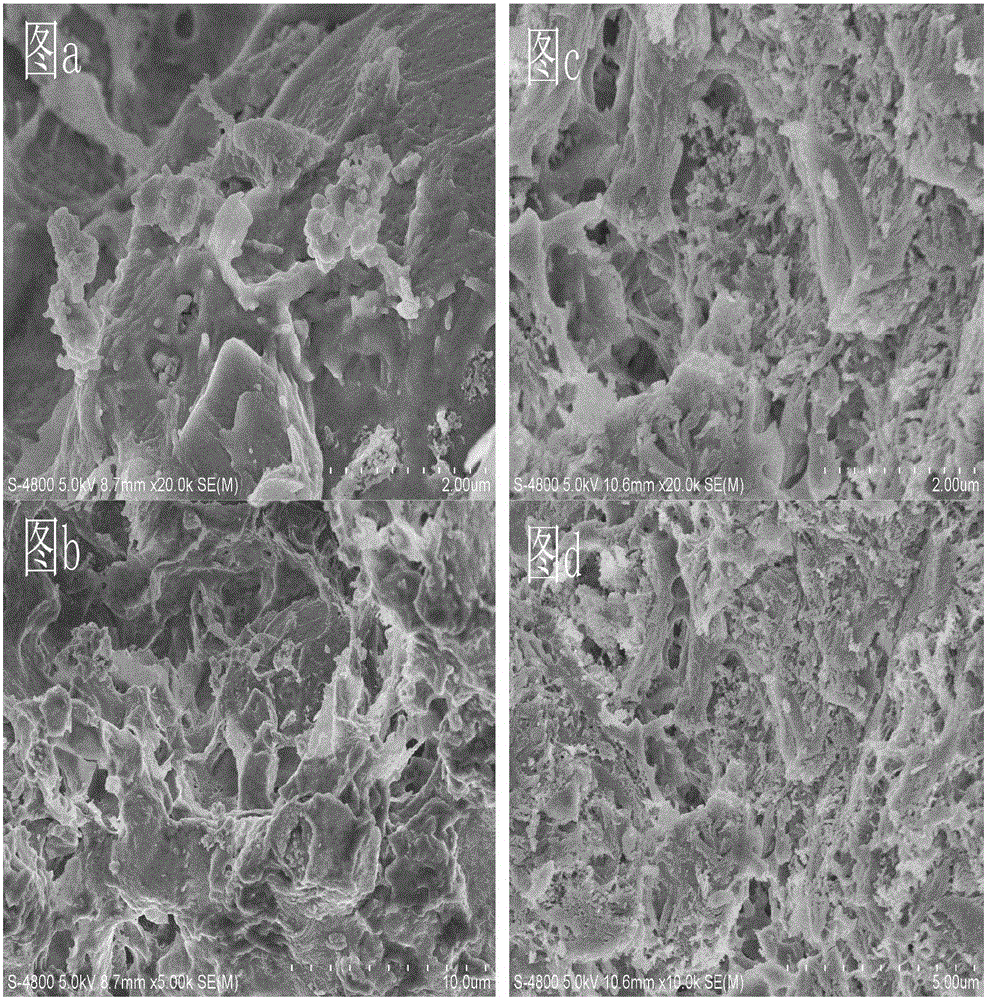

Image

Examples

Embodiment 1

[0036] (1) Preparation of raw materials:

[0037] a. The attapulgite is pulverized by a pulverizer, passed through a 200-mesh sieve, and dried in an oven for more than 2 hours to obtain attapulgite powder.

[0038] b. After passing the rice husk powder through an 80-mesh sieve, put it in an oven to dry for more than 2 hours to obtain the rice husk powder.

[0039] c. After passing the fly ash through a 200-mesh sieve, put it in an oven to dry for more than 2 hours to obtain fly ash.

[0040] (2) stirring:

[0041] The powder is mixed according to the mass percentage of attapulgite: rice husk powder: fly ash = 3:0:2, and stirred by a mixer for more than 1 hour to stir evenly.

[0042] (3) Add water to granulate:

[0043] Add deionized water to the mixed powder and stir evenly. The amount of water added is 25% of the mass of the mixed powder to make spherical particles of 3-5mm, and then placed in an oven and dried at 105°C for more than 2 hours.

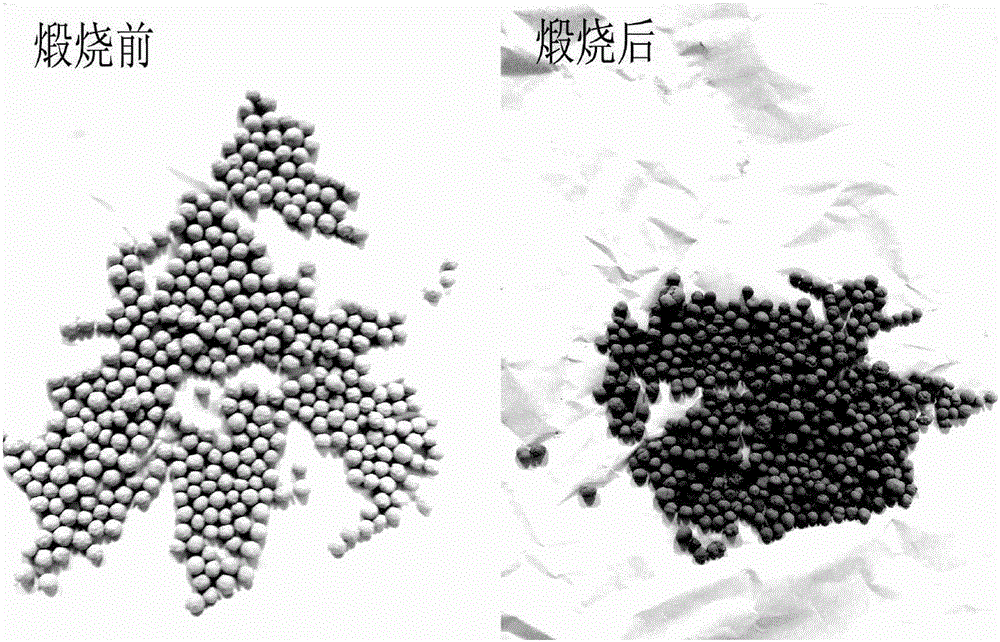

[0044] (4) Calcination:

...

Embodiment 2

[0047] (1) Preparation of raw materials:

[0048] a. The attapulgite is pulverized by a pulverizer, passed through a 200-mesh sieve, and dried in an oven for more than 2 hours to obtain attapulgite powder.

[0049] b. After passing the sawdust powder through an 80-mesh sieve, put it in an oven to dry for more than 2 hours to obtain the sawdust powder.

[0050] c. After passing the fly ash through a 200-mesh sieve, put it in an oven to dry for more than 2 hours to obtain fly ash.

[0051] (2) stirring:

[0052] The powder is mixed according to the mass percentage of attapulgite: sawdust powder: fly ash = 7:1:2, and stirred by a mixer for more than 1 hour to stir evenly.

[0053] (3) Add water to granulate:

[0054] Add 1% sodium bicarbonate solution to the mixed powder and stir evenly, add water 25% of the mixed powder mass to make 3-5mm spherical particles, then place them in an oven and dry at 105°C More than 2 hours.

[0055] (4) Calcination:

[0056]The dried ceramsit...

Embodiment 3

[0058] (1) Preparation of raw materials:

[0059] a. Attapulgite is pulverized through a pulverizer, and after passing through a 200 mesh sieve, put it in an oven to dry for more than 2 hours to obtain attapulgite powder.

[0060] b. Pass the chestnut shell powder through an 80-mesh sieve, and put it in an oven to dry for more than 2 hours to obtain the chestnut shell powder.

[0061] c. After passing the fly ash through a 200-mesh sieve, put it in an oven to dry for more than 2 hours to obtain fly ash.

[0062] (2) stirring:

[0063] The powder is mixed according to the mass percentage of attapulgite: chestnut shell powder: fly ash = 18:7:5, and stirred by a mixer for more than 1 hour to stir evenly.

[0064] (3) Add water to granulate:

[0065] Add 1% by mass sodium bicarbonate solution to the mixed powder and stir evenly, add 25% of the mass of the mixed powder to make 3-5mm spherical particles, then place them in an oven and dry at 105°C More than 2 hours.

[0066] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Average compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com