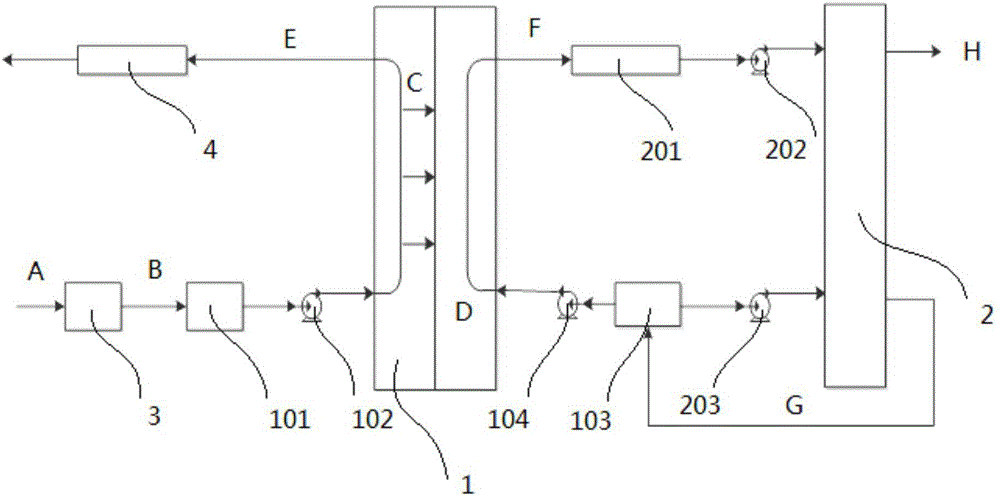

Forward osmosis draw fluid recycling method, wastewater treatment method and treatment device

A technology of recycling and treatment methods, applied in the direction of osmosis/dialysis water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of limited types of draw liquid, poor operation safety, and high energy consumption. To achieve the effect of prolonging the continuous and stable operation time, low operation cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The water quality characteristics of the high-salt wastewater to be treated (oilfield fracturing fluid wastewater of a certain high-salt wastewater) are: wastewater pH 8.35, electrical conductivity about 20000μs / cm, CODcr 8350mg / L, Cl - 43500mg / L, oil: 80mg / L, suspended matter: 1000mg / L.

[0048] The forward osmosis membrane module used is a cellulose acetate plate-and-frame membrane module; the ion-exchange membrane is a styrene-divinylbenzene copolymer membrane plate-and-frame membrane module, and the membrane pore diameter is 0.2 μm.

[0049] The pretreatment steps include high-efficiency oil separation and air flotation tanks to remove oil, and high-efficiency suspension sedimentation tanks to remove suspended matter.

[0050] The drawing solution is magnesium sulfate solution. During the operation of the wastewater treatment unit, under the operating conditions of the forward osmosis process: feed liquid side, wastewater pH 8.35, wastewater temperature 25°C, membra...

Embodiment 2

[0054] The water quality characteristics of the high-salt wastewater to be treated (reverse osmosis concentrated water from sewage treatment plant): wastewater pH8, electrical conductivity around 20000μs / cm, CODcr 15000mg / L, Ca 2+ About 30mg / L, Mg 2+ About 20mg / L, soluble silicon about 50mg / L, NH 3 -N 1000mg / L or so. This water is pretreated landfill leachate water.

[0055] The forward osmosis membrane module used is a cellulose acetate plate-and-frame membrane module; the ionic membrane module used is a styrene-divinylbenzene copolymer membrane plate-and-frame membrane module, and the membrane pore diameter is 0.2 μm.

[0056] The pretreatment steps include high-efficiency suspension sedimentation tanks to remove suspended solids.

[0057] The drawing solution is magnesium sulfate solution. During the operation of the wastewater treatment unit, under the operating conditions of the forward osmosis process: feed liquid side, wastewater pH 8, wastewater temperature 25°C, me...

Embodiment 3

[0061] The high-salt wastewater to be treated belongs to the reverse osmosis concentrated water of the coal chemical industry. The water quality characteristics: pH 8.0, TDS23935mg / L, CODcr 300mg / L, Cl - 13812mg / L, Na + 8749mg / L, HCO 3 - 882mg / L, Ca 2+ 399mg / L.

[0062] The forward osmosis membrane module used is a cellulose acetate plate-and-frame membrane module; the ionic membrane module used is a styrene-divinylbenzene copolymer membrane plate-and-frame membrane module, and the membrane pore diameter is 0.2 μm.

[0063] Pretreatment steps include high-efficiency sedimentation tanks to remove suspended solids.

[0064] The draw solution is calcium sulfate solution. During the operation of the wastewater treatment device, under the operating conditions of the forward osmosis process: feed liquid side, wastewater pH8, wastewater temperature 25 ° C, membrane surface flow rate 0.5m / s, forward osmosis membrane flux maintains at 5L / m 2 About h; under the operating condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com