Method for removing barium sulfate impurity from lead dioxide

A technology of lead dioxide and barium sulfate, applied in the direction of lead dioxide and lead oxide, which can solve the problems of reducing oxygen evolution overpotential, affecting the capacity and life of lead-acid batteries, and achieving the effect of reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

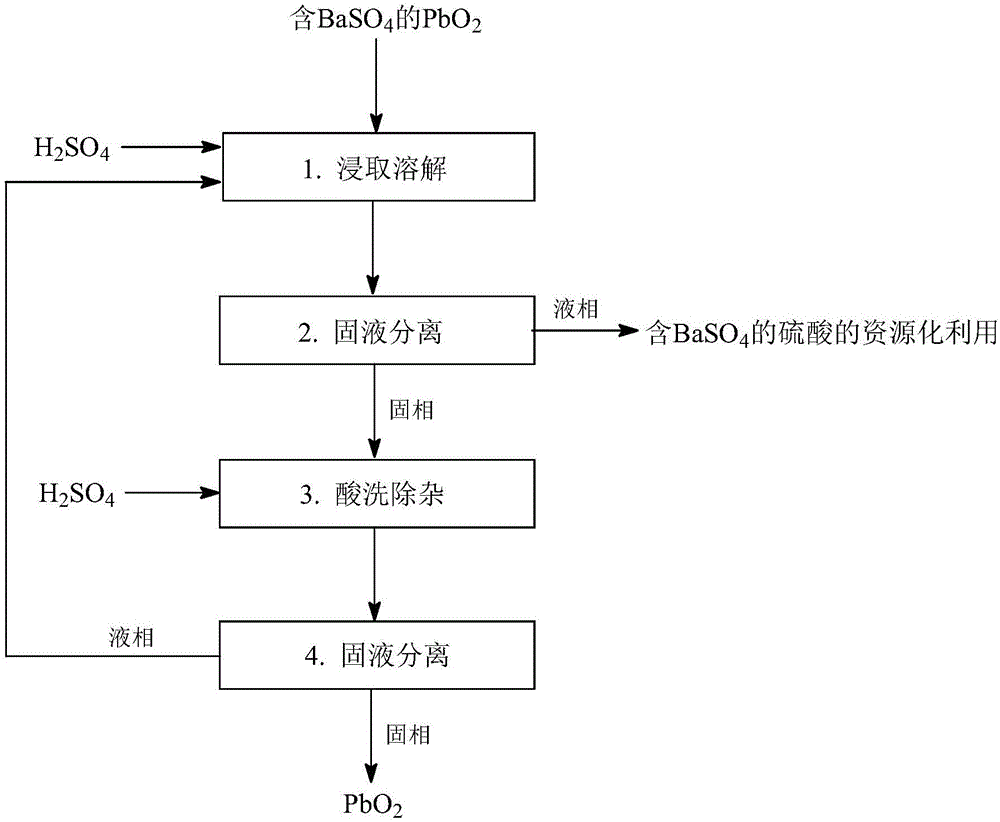

[0043] Such as figure 1 As shown, a method for removing barium sulfate impurities in lead dioxide, using lead dioxide containing barium sulfate as raw material, using concentrated sulfuric acid as leaching agent and detergent, adopts leaching and dissolving-pickling to remove impurities-solid A process method for preparing sulfuric acid solution containing lead dioxide and barium sulfate by liquid separation coupling technology. The specific method steps are as follows:

[0044] (1) Leaching and dissolving: in the stirred tank type leaching and dissolving equipment, lead dioxide containing 0.5% barium sulfate and 15.6mol / L sulfuric acid are mixed and leached, and the consumption ratio of lead dioxide and leaching agent is 1.0kg: 1.0L, the operating temperature is 60°C, the barium sulfate in lead dioxide is leached and dissolved in concentrated sulfuric acid, and the material after leaching, dissolving and removing impurities enters the next step;

[0045] (2) Solid-liquid se...

Embodiment 2

[0049] (1) leaching and dissolving: in the dynamic mixer leaching and dissolving equipment, the lead dioxide containing 2.0% barium sulfate is mixed with 18.6mol / L sulfuric acid, leaching, the consumption ratio of lead dioxide and leaching agent is 1.0kg: 1.0L, the operating temperature is 20°C, the barium sulfate in the lead dioxide is leached and dissolved in the concentrated sulfuric acid solution, and the material after leaching, dissolving and removing impurities enters the next step;

[0050] (2) Solid-liquid separation: In the drum-type vacuum filtration solid-liquid separation equipment, the material obtained in the previous step is subjected to solid-liquid separation, and the liquid phase material obtained through solid-liquid separation can be further separated and removed to realize resource utilization , the obtained solid phase material enters the next step;

[0051] (3) Pickling and impurity removal: In the stirred tank type washing and impurity removal equipmen...

Embodiment 3

[0054] (1) Leaching and dissolving: In the stirred tank type leaching and dissolving equipment, lead dioxide containing 1.5% barium sulfate and 18.0mol / L sulfuric acid are mixed and leached, and the consumption ratio of lead dioxide and leaching agent is 1.0kg: 4.0L, the operating temperature is 30°C, the barium sulfate in the lead dioxide is leached and dissolved in the concentrated sulfuric acid solution, and the material after leaching, dissolving and removing impurities enters the next step;

[0055] (2) Solid-liquid separation: In the solid-liquid separation equipment of the centrifuge, the material obtained in the previous step is subjected to solid-liquid separation, and the liquid phase material obtained through solid-liquid separation can be further separated and removed to realize resource utilization. The phase material enters the next step;

[0056] (3) Pickling and impurity removal: In the stirred tank type washing and impurity removal equipment, the material obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com