Method for improving thermal stability of collagen through ultrahigh pressure treatment

An ultra-high pressure, thermally stable technology that can be used in the field of medical biomaterials to solve problems such as reduced biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

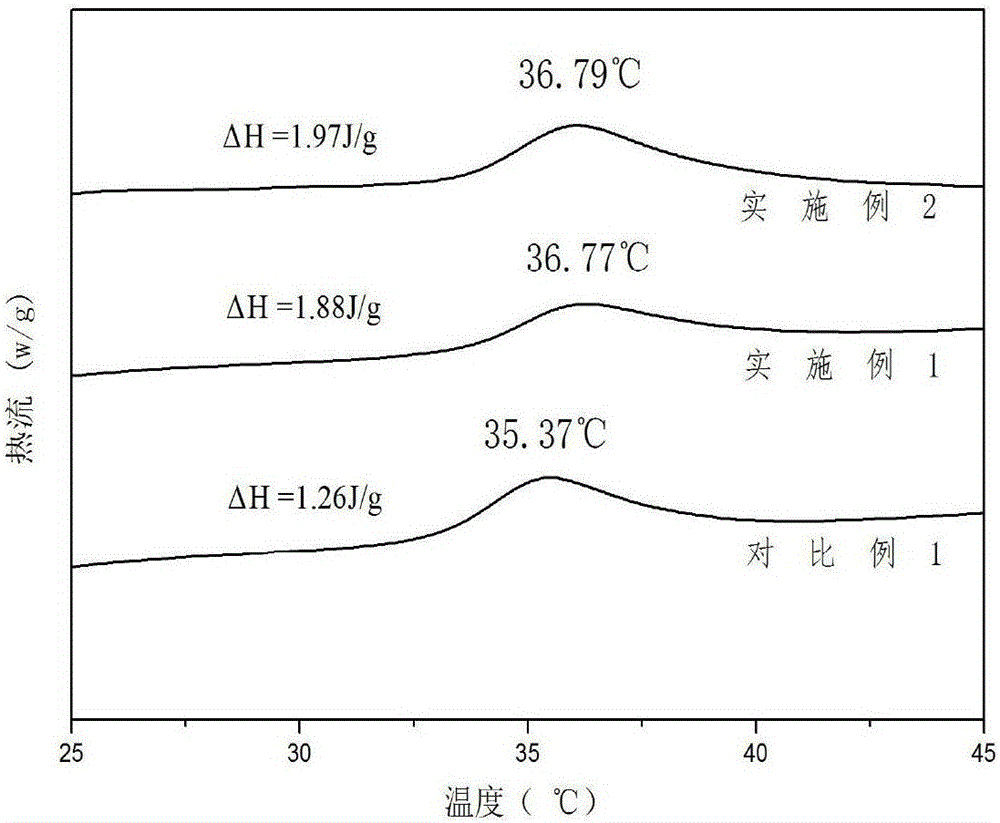

Embodiment 1

[0025] Bullfrog skin was selected as raw material, natural collagen was extracted by acetic acid combined with pepsin, the extract was purified by salting out, dialysis and other methods, and then freeze-dried to obtain bullfrog enzyme-soluble collagen products. The collagen was analyzed by SDS-PAGE and circular dichroism (CD), and it was confirmed that it was a natural type I collagen with a complete triple helix molecular structure. Under the condition of ice bath, the collagen was dissolved with acetic acid aqueous solution (to obtain a collagen solution with a concentration of 3 mg / mL), and then the collagen solution was placed in a polyethylene bag, which was vacuum-sealed and packaged by a vacuum packaging machine. The packaging bag is placed in an ultra-high pressure container, and water is used as a pressure transmission liquid medium for ultra-high pressure treatment. The treatment conditions are as follows: the pressure is 300MPa, the time for the pressure holding tr...

Embodiment 2

[0027] Bullfrog skin was selected as raw material, natural collagen was extracted by acetic acid combined with pepsin, the extract was purified by salting out, dialysis and other methods, and then freeze-dried to obtain bullfrog enzyme-soluble collagen products. The collagen was analyzed by SDS-PAGE and circular dichroism (CD), and it was confirmed that it was a natural type I collagen with a complete triple helix molecular structure. Under the condition of ice bath, the collagen was dissolved with acetic acid aqueous solution (to obtain a bullfrog skin collagen solution with a concentration of 2 mg / mL), and then the bullfrog skin collagen solution was placed in a polypropylene bag, which was vacuum-sealed and packaged by a vacuum packaging machine. The packaging bag is placed in an ultra-high pressure container, and water is used as a pressure transmission liquid medium for ultra-high pressure treatment. The treatment conditions are as follows: the pressure is 200MPa, the tim...

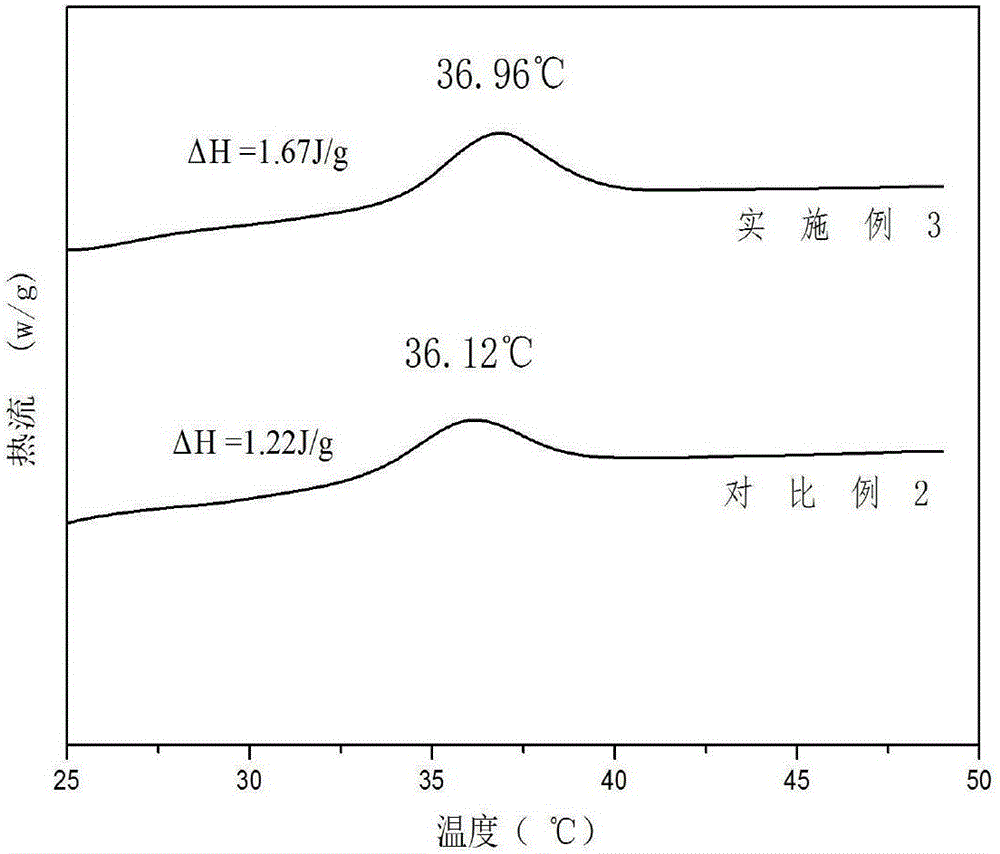

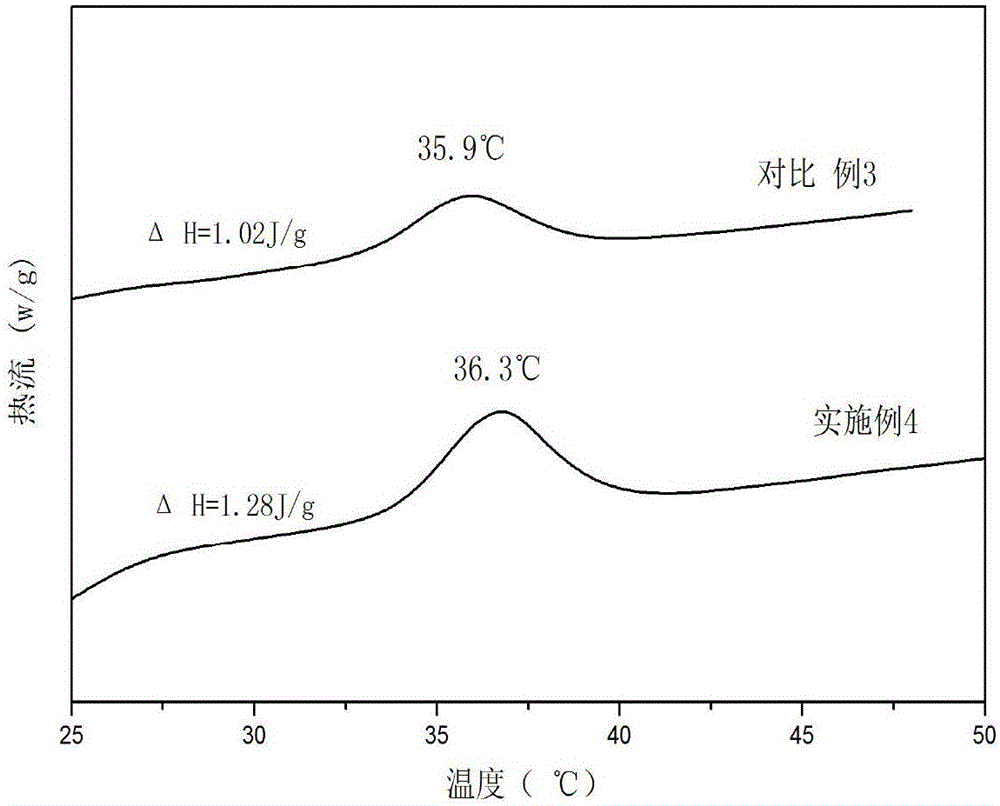

Embodiment 3

[0029] Grass carp skin was selected as raw material, and natural collagen was extracted by using acetic acid as a solvent. The extract was purified by salting out, dialysis and other methods, and then freeze-dried to obtain grass carp acid-soluble collagen products. The collagen was analyzed by SDS-PAGE and circular dichroism (CD), and it was confirmed that it was a natural type I collagen with a complete triple helix molecular structure. Under the condition of ice bath, the collagen was dissolved with acetic acid aqueous solution (to obtain a grass carp skin collagen solution with a concentration of 3 mg / mL), and then the grass carp skin collagen solution was placed in a polyethylene bag, which was vacuum sealed and packaged by a vacuum packaging machine. The packaging bag is placed in an ultra-high pressure container, and water is used as a pressure transmission liquid medium for ultra-high pressure treatment. The treatment conditions are as follows: the pressure is 300MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thermal denaturation | aaaaa | aaaaa |

| Thermal denaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com