Colored glossy pigment using vegetable type natural dye and method for preparing same

A technology of natural dyes and natural pigments, applied in the direction of natural dyes, organic dyes, pigment pastes, etc., can solve problems such as the limitation of raw materials, and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

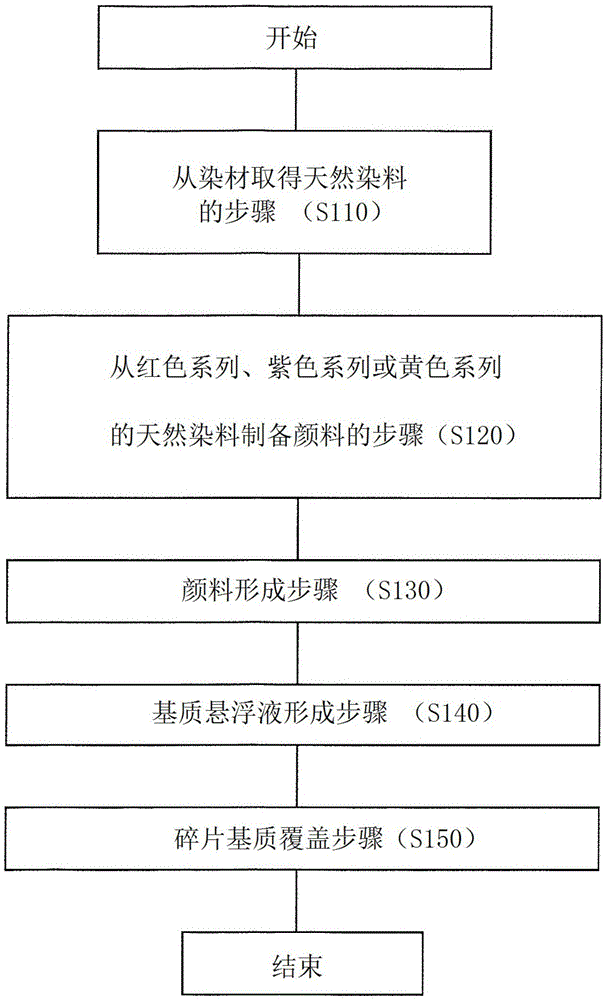

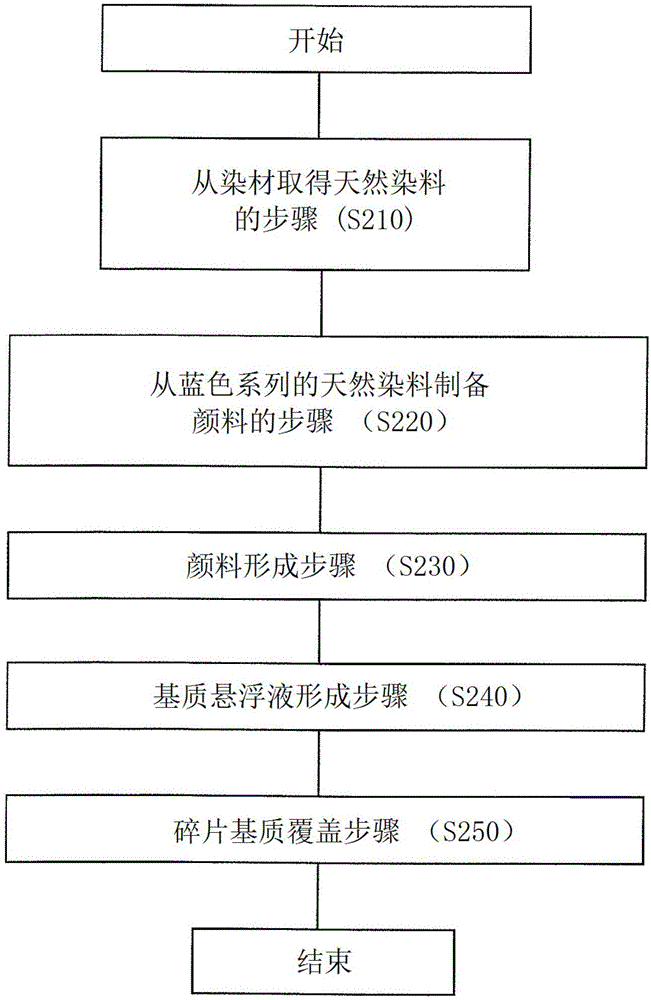

[0022] refer to figure 1 , the preparation method of the colored luster pigment that utilizes natural dyestuff according to an embodiment of the present invention comprises: Step S110, obtain natural dyestuff from dyeing material; Step S120, S130, after titrating inorganic salt solution in natural dyestuff, pH adjustment is neutral state, to prepare natural pigments comprising natural dyes; matrix suspension forming step S140, comprising one of synthetic mica, natural mica, glass, platy iron oxide, platy alumina, platy silica, talc and bismuth After mixing the above kinds of chip substrates and the pigment composition coated with metal oxides in deionized water, stirring and dispersing; and the natural pigment covering step S150, mixing the acidity regulator and the above-mentioned pigments in the above-mentioned substrate suspension, and then The surface of the aforementioned chip matrix is covered with an oxide layer.

[0023] The dye preparation step S110 includes: a dy...

Embodiment 1

[0070] Preparation of red series natural pigments

[0071] (1) Preparation of red natural pigment

[0072] Heating in deionized water (or organic solvent) extracted from sumac [comprising one selected from sumac bark extract (CAESALPINIA SAPPAN BARK EXTRACT), sumac dry powder (CAESALPINIA SAPPAN STEM POWDER) or A mixture of more than one natural dye] to extract the dye solution, and concentrate the dye solution to vacuum-dry and prepare the dye. Put 10 parts by weight of hematoxylin into a 2L beaker, and drop into 100 parts by weight of deionized water and 30 parts by weight of CaCl 2 , to stir at 200rpm. At this time, the reaction temperature was set at 40° C., and potassium hydroxide was charged. The pH was adjusted to 7, and the solution was stirred, and when a precipitate started to appear, the above precipitate was dehydrated, dried, pulverized, and used as a pigment.

[0073] (2) Preparation of red natural pigment ink

[0074] 140 parts by weight of deionized water ...

Embodiment 2

[0084] Preparation of natural pigments of the yellow series

[0085] (1) Preparation of yellow natural pigment

[0086] A natural dye extracted from gardenia which is a natural dye dyeing material is heated in deionized water (or an organic solvent) to extract a dye solution, and the dye solution is concentrated for vacuum drying to prepare a dye. Put 20 parts by weight of gardenia dye into a 2L beaker, and drop into 100 parts by weight of deionized water and 30 parts by weight of AlCl 3 , to stir at 200rpm. At this time, the reaction temperature was set at 60° C., and sodium hydroxide was added. The pH was adjusted to 7, and the solution was stirred, and when a precipitate started to appear, the above precipitate was dehydrated, dried, pulverized, and used as a pigment.

[0087] (2) Preparation of yellow natural pigment ink

[0088] 140 parts by weight of deionized water and 60 parts by weight of gardenia pigment were put into a 500 mL beaker, and ground for 12 hours at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com